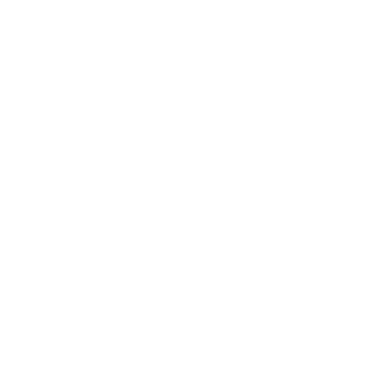

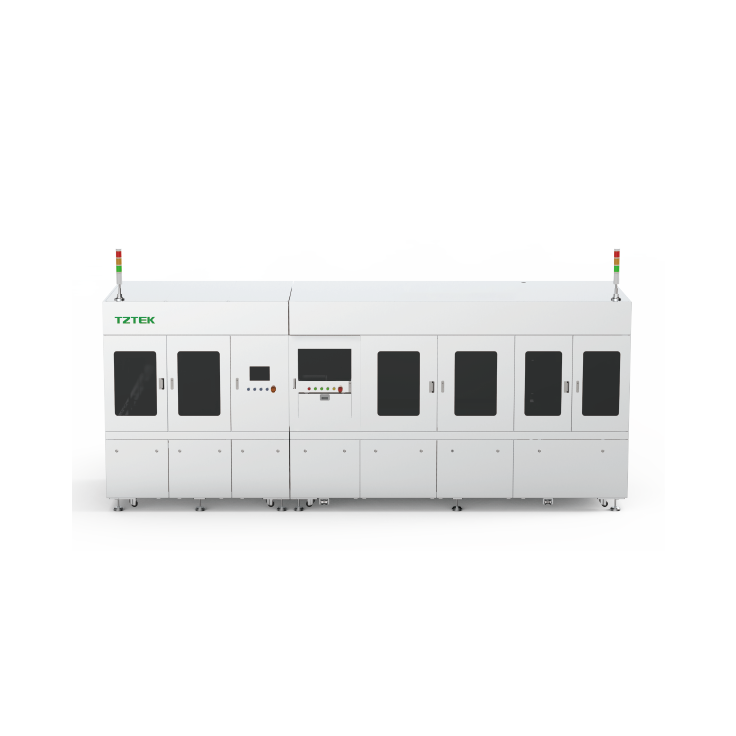

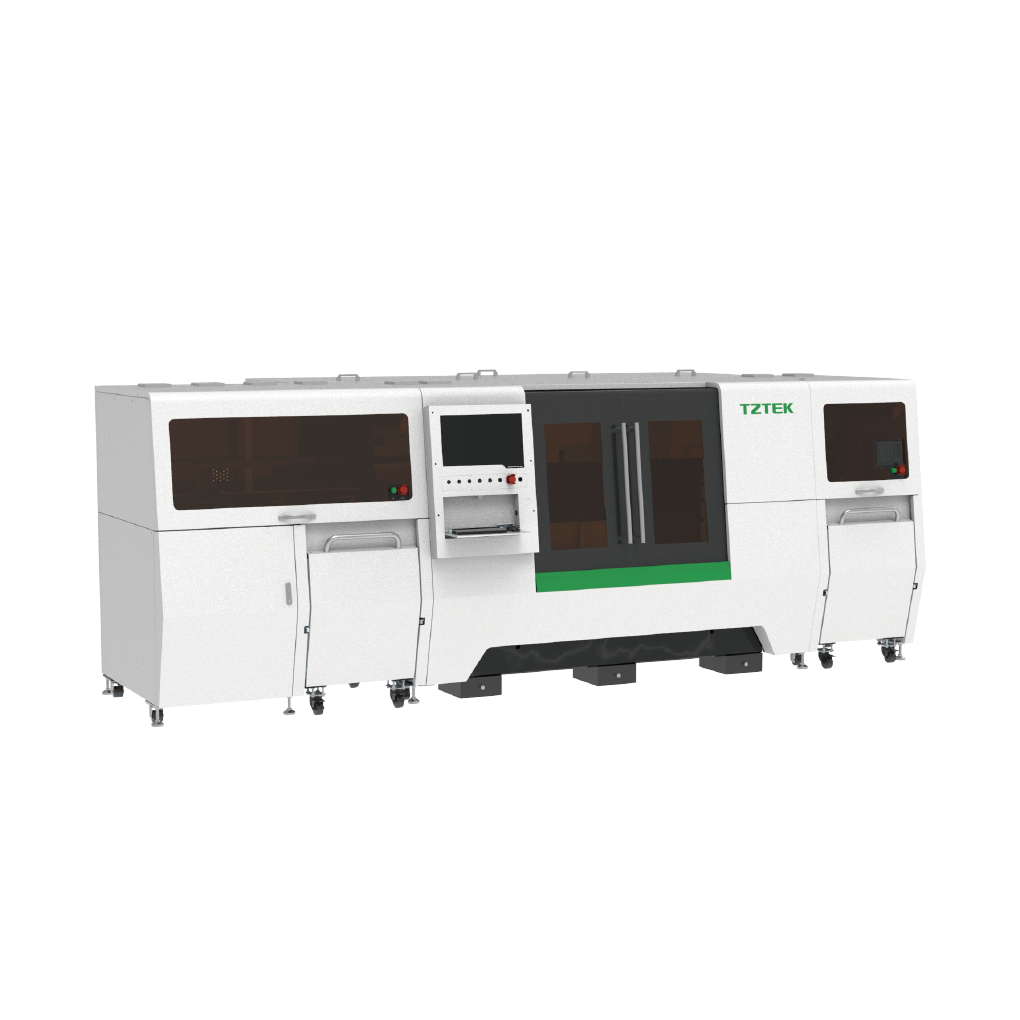

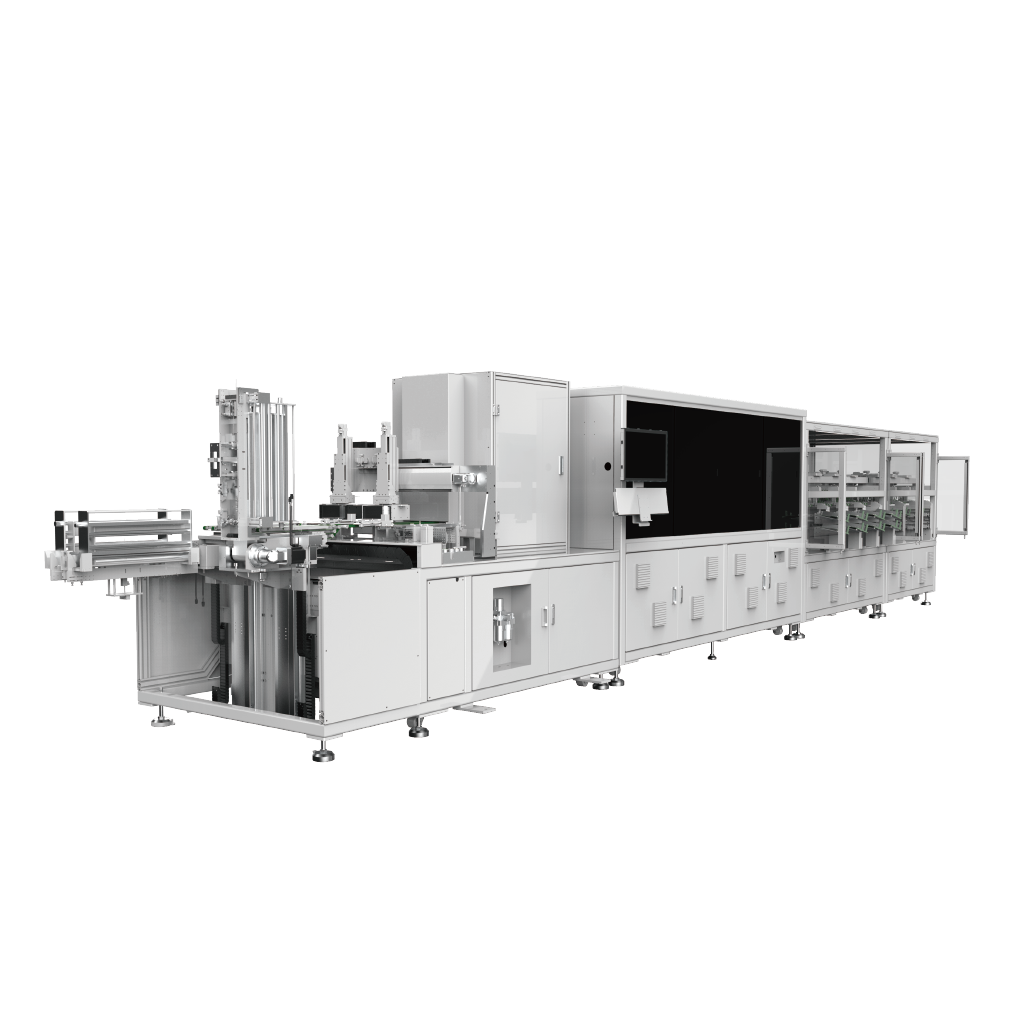

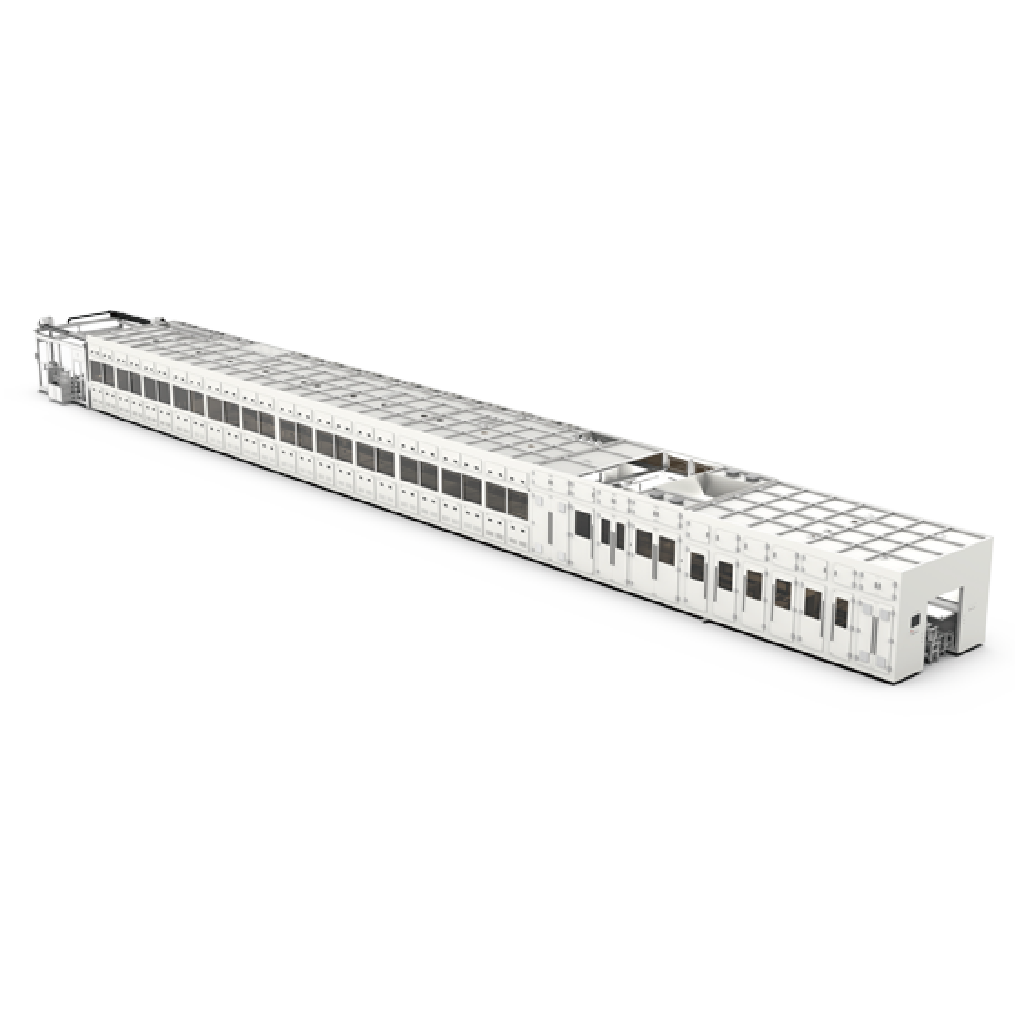

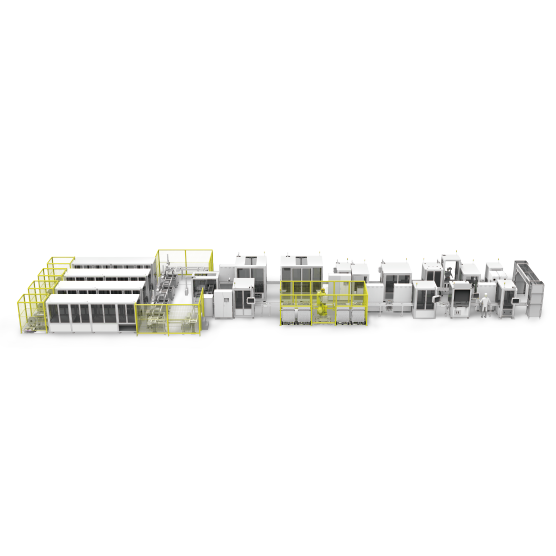

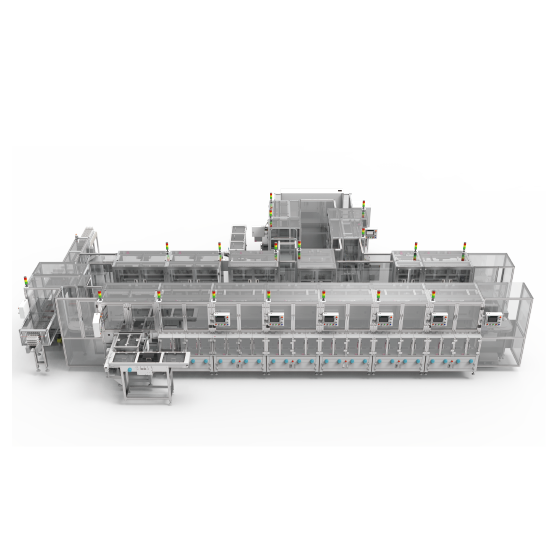

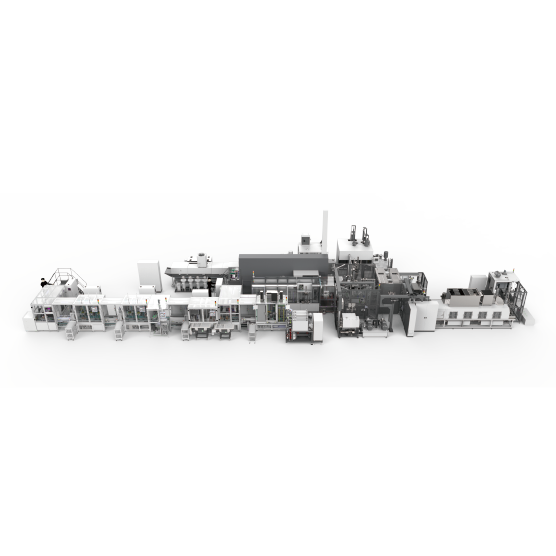

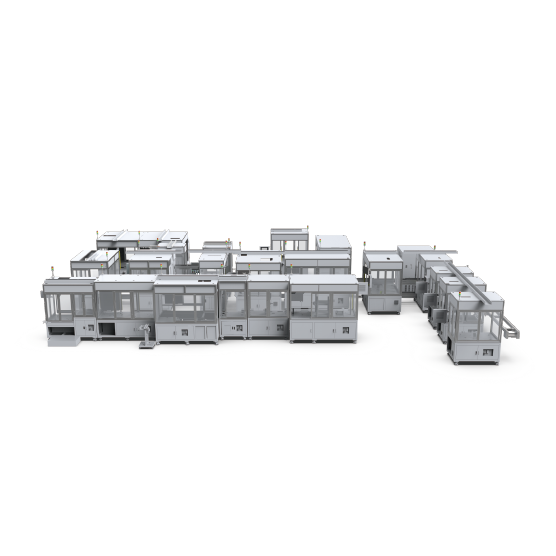

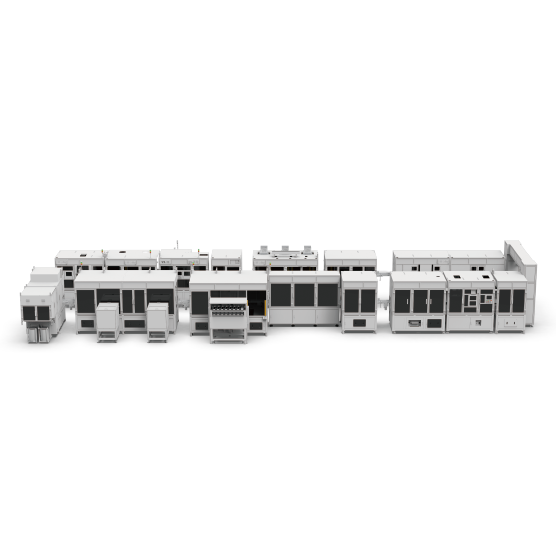

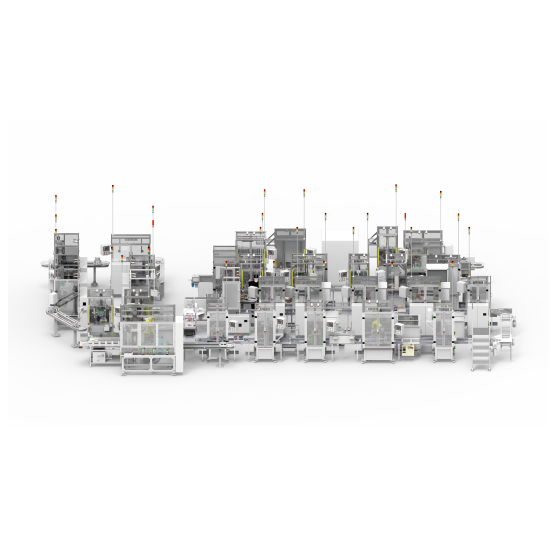

Multi-in-One Drive Motor Assembly Smart Production Line

Advantages

-

High Flexibility

-

High Automation Level

-

Integrated Design

-

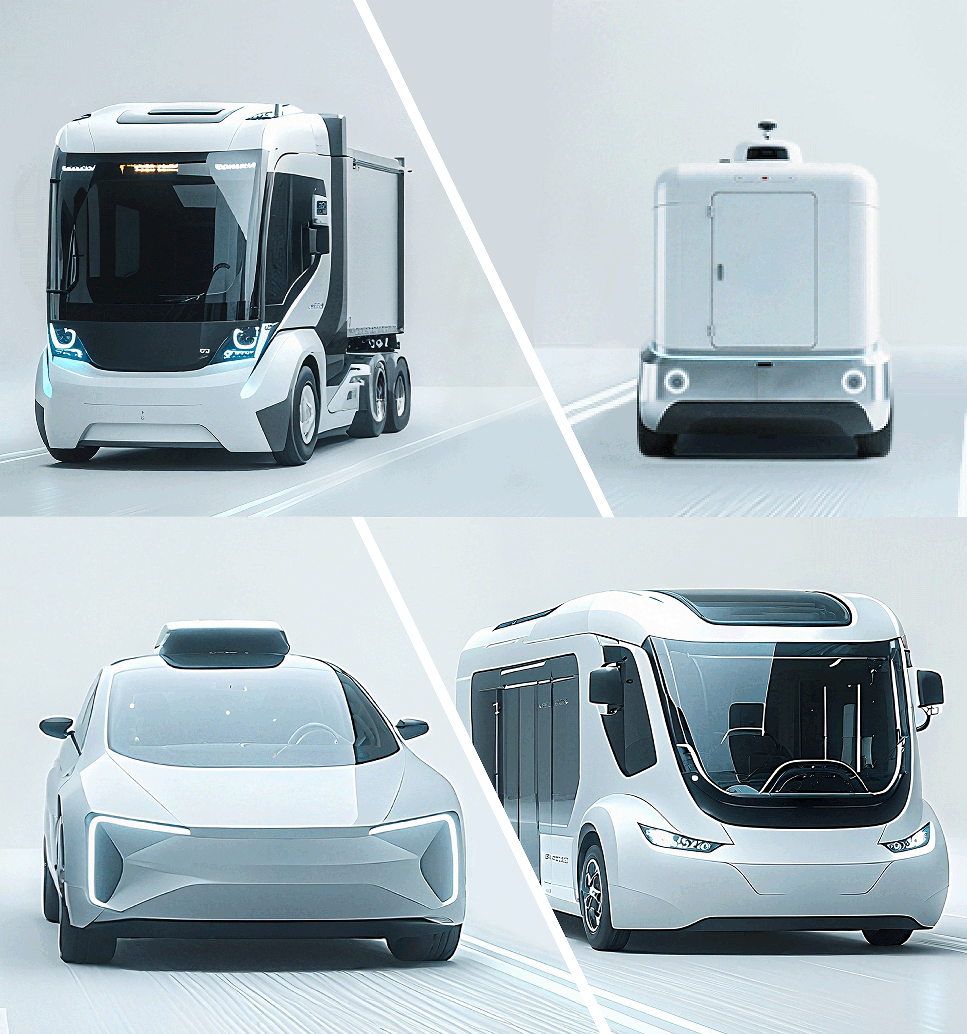

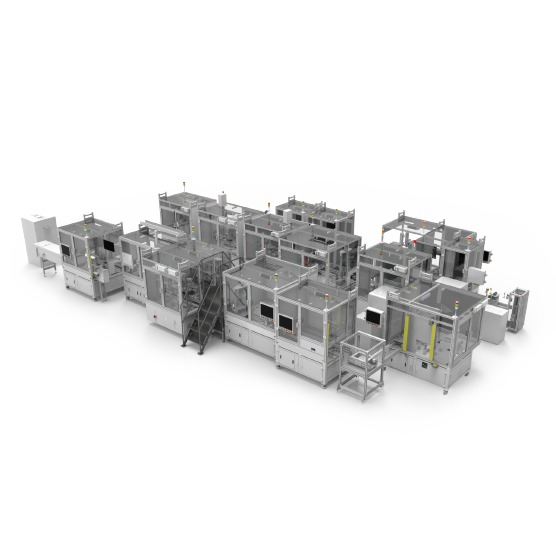

High Flexibility

High FlexibilityCompatible with multiple product variants and featuring short changeover times, enabling rapid switching between different specifications to meet the diverse demands of the NEV market.

-

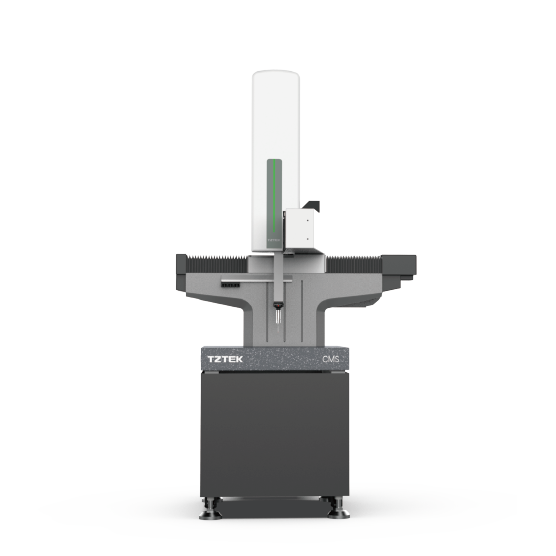

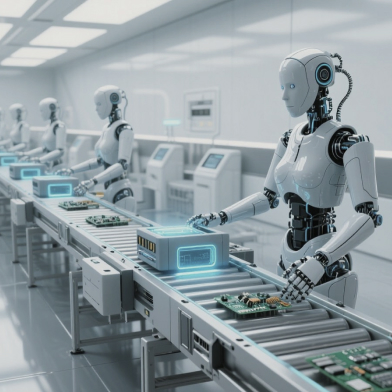

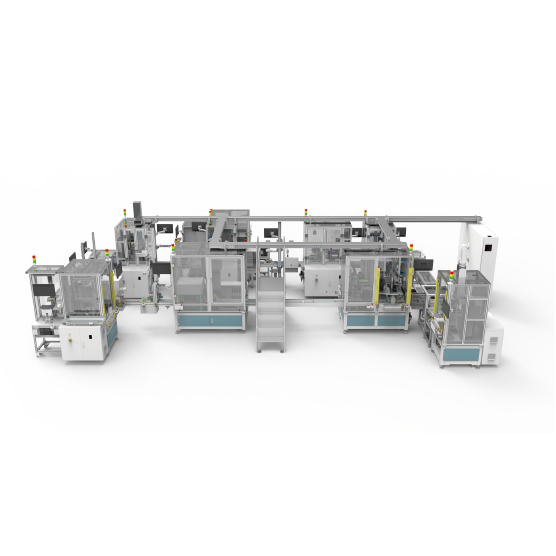

High Automation Level

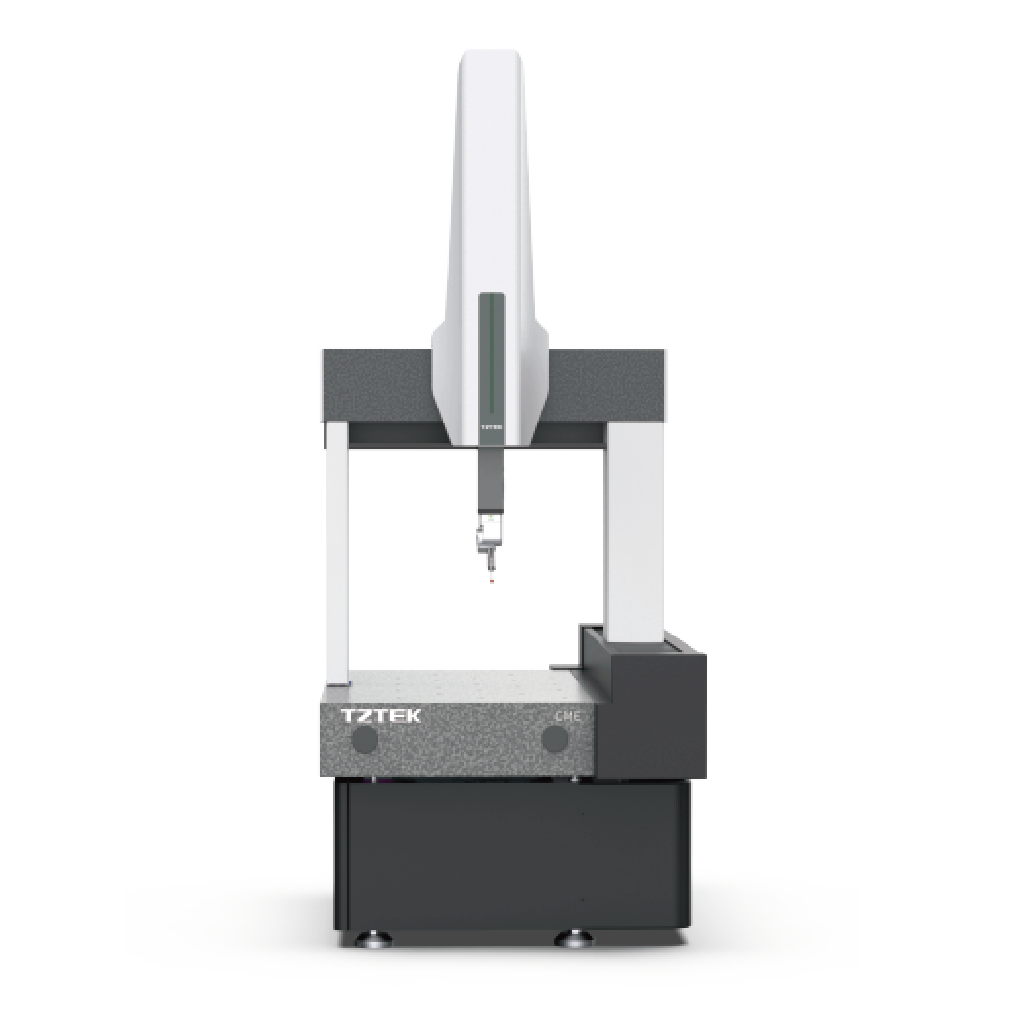

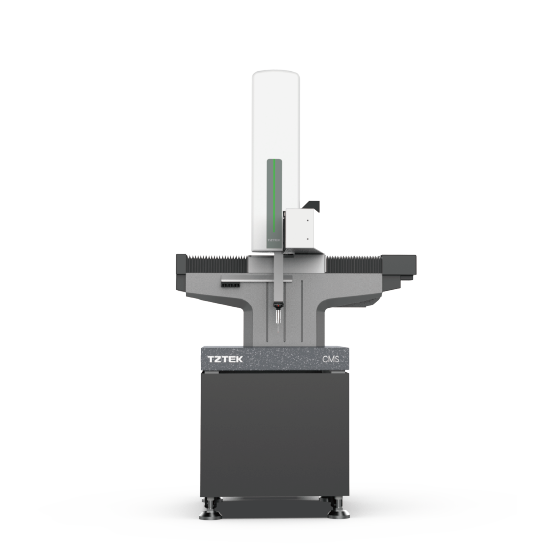

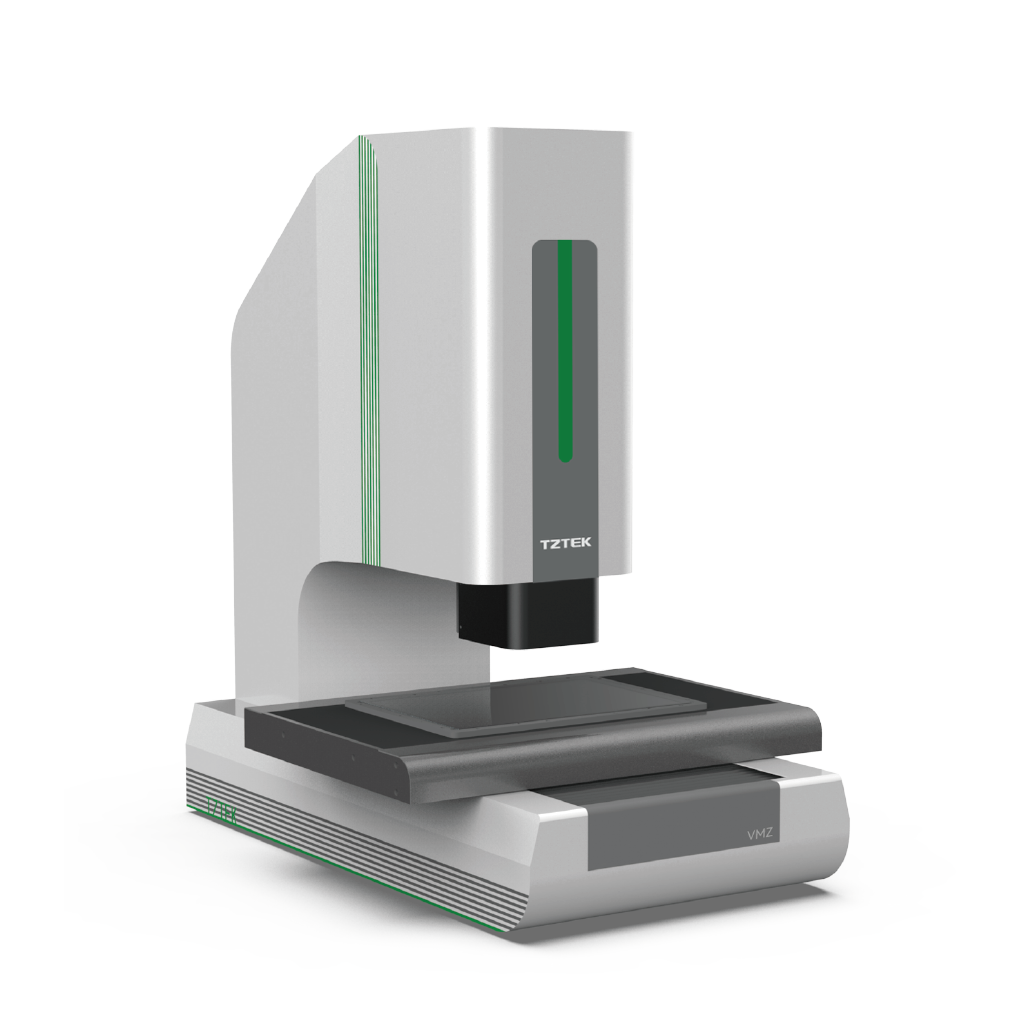

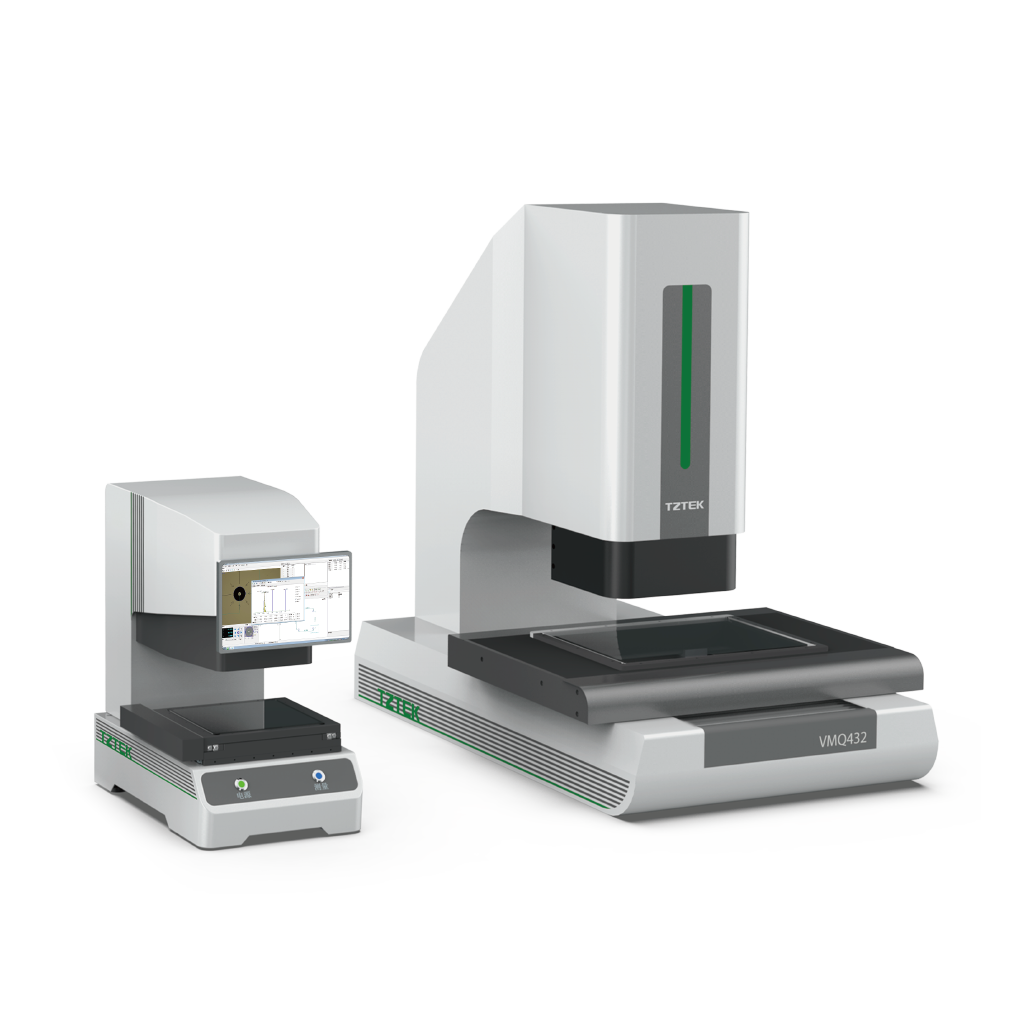

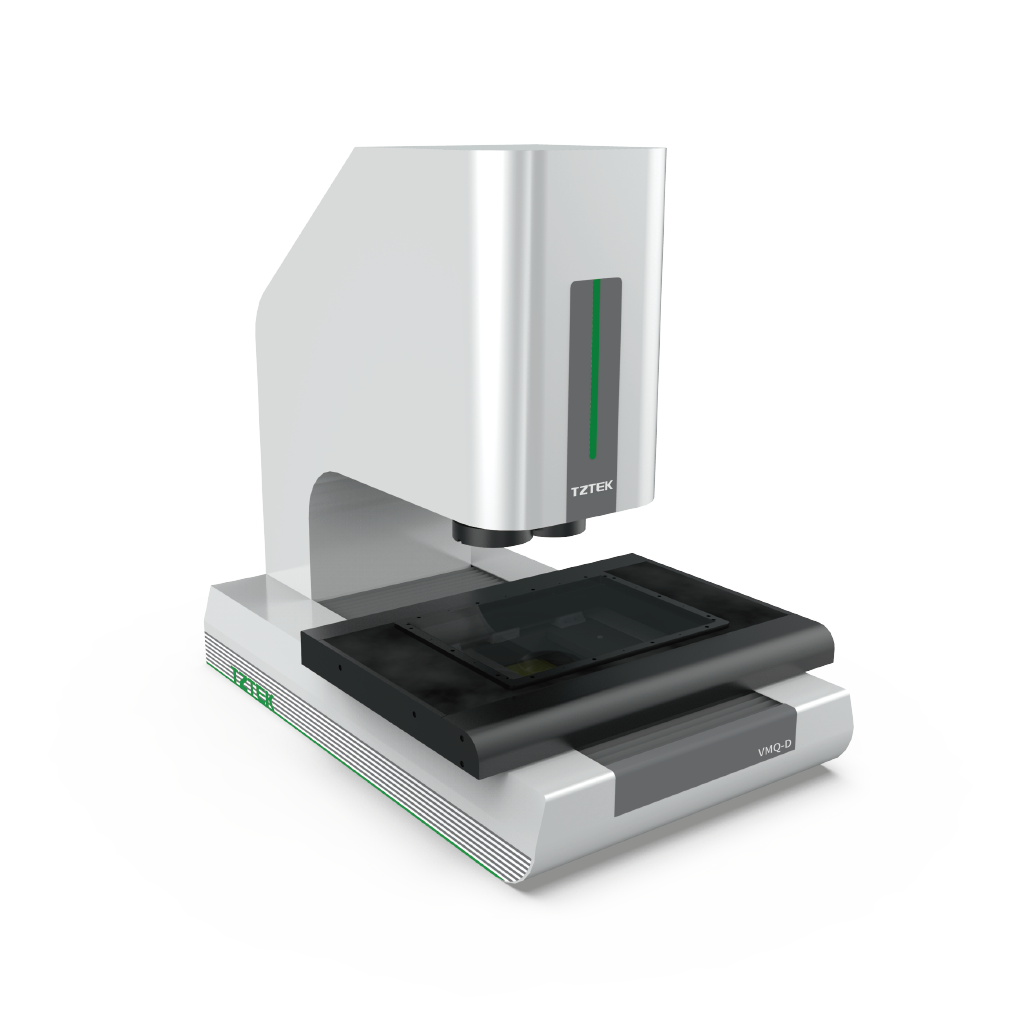

High Automation LevelEquipped with 6-axis robots and automated testing equipment to achieve high-precision assembly and quality inspection, boosting production efficiency.

-

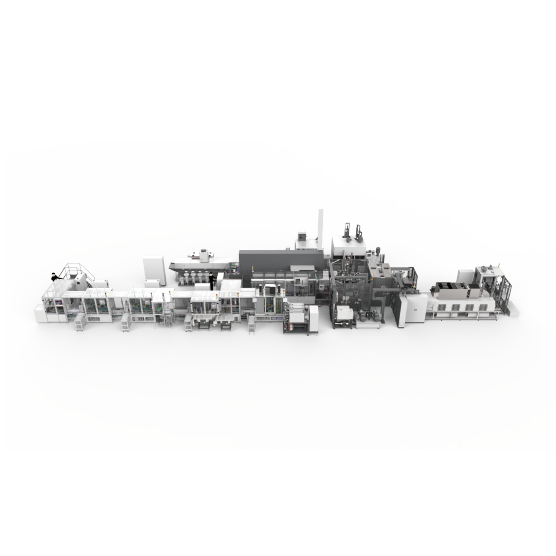

Integrated Design

Integrated DesignIntegrates key components (motor, gearbox, controller, etc.) with shared housings and wiring harnesses, enabling cost reduction, weight savings, miniaturization, and optimized vehicle spatial layout.