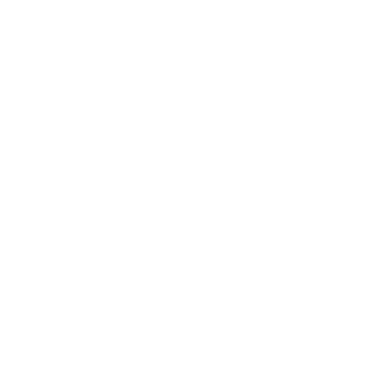

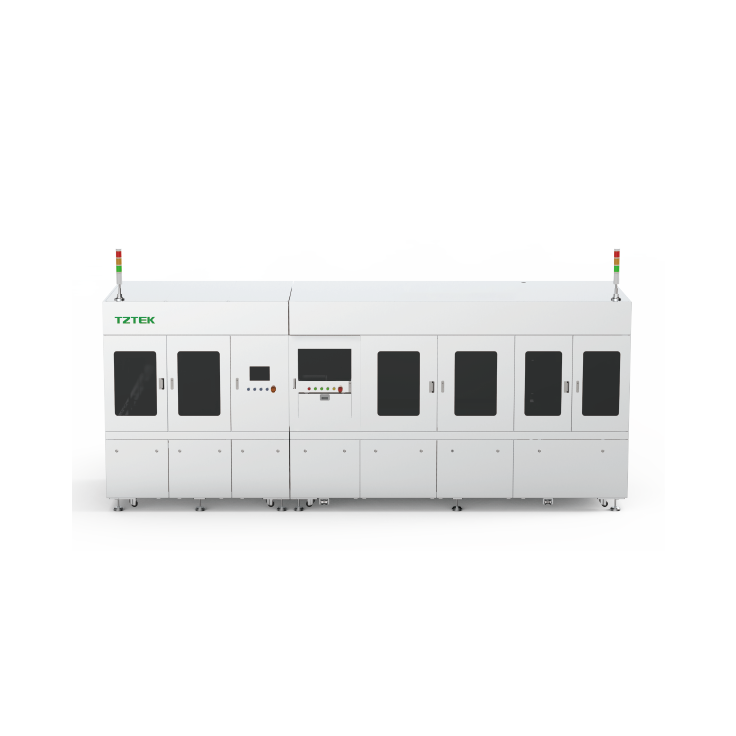

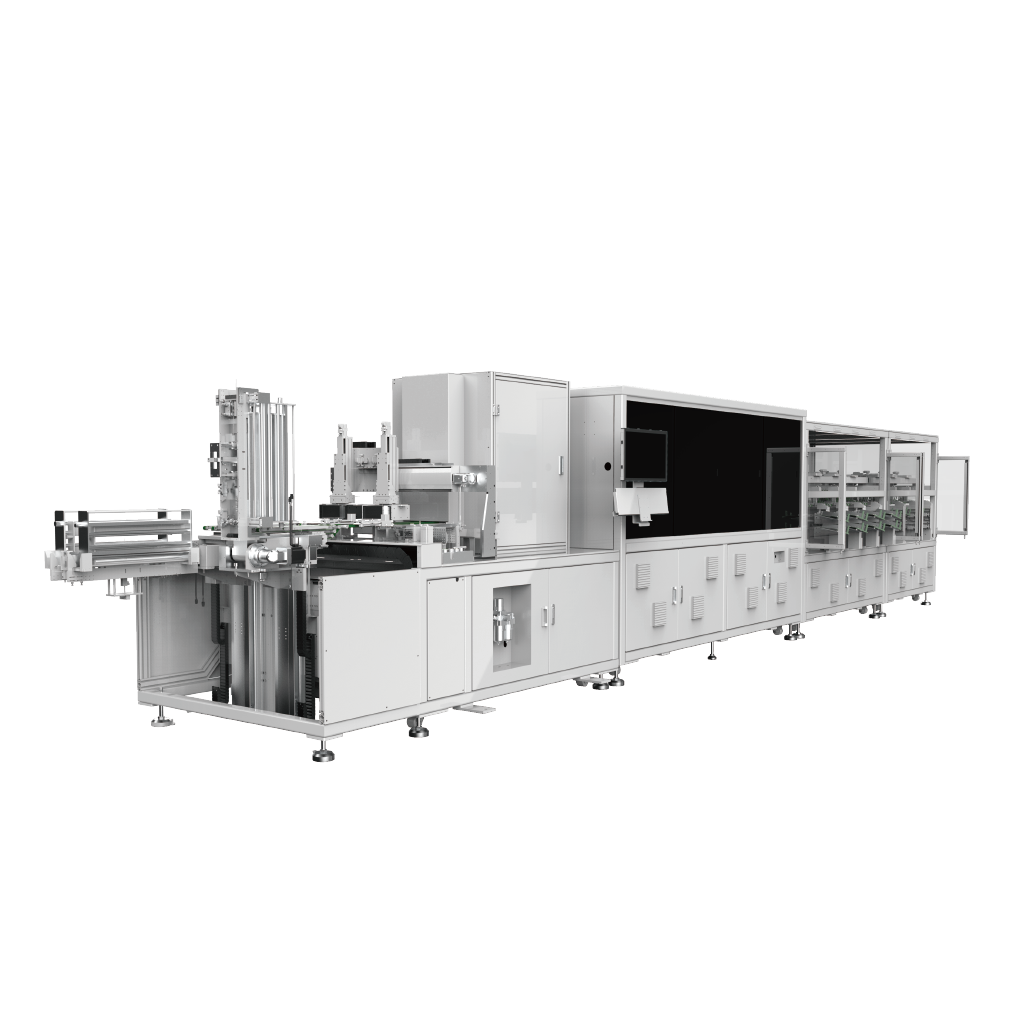

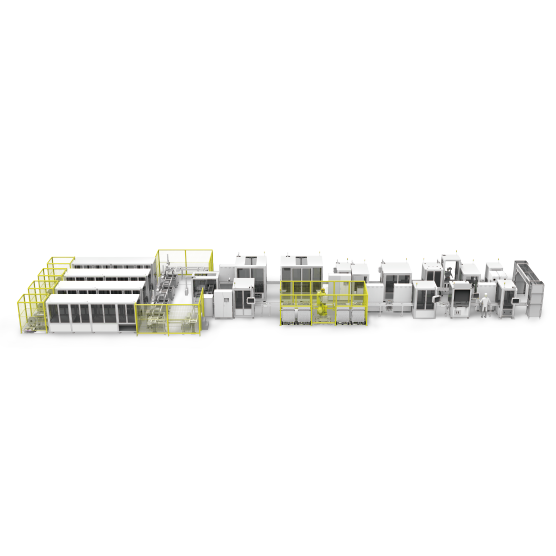

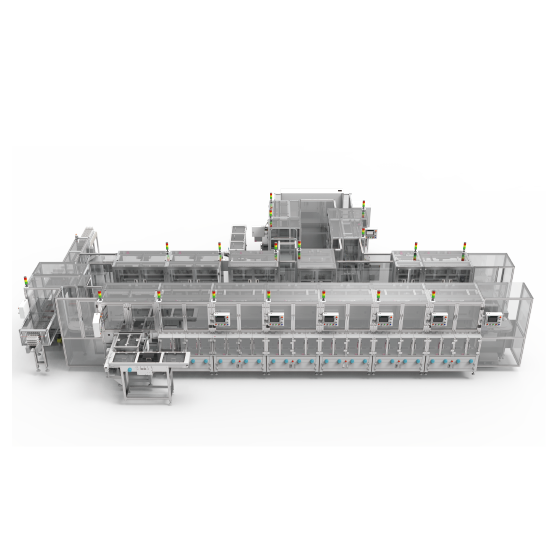

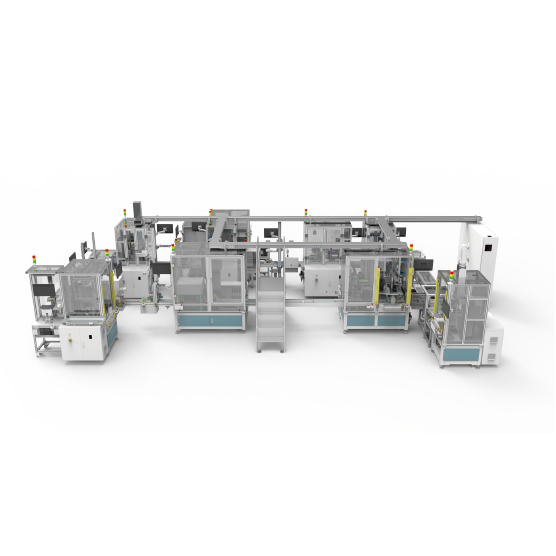

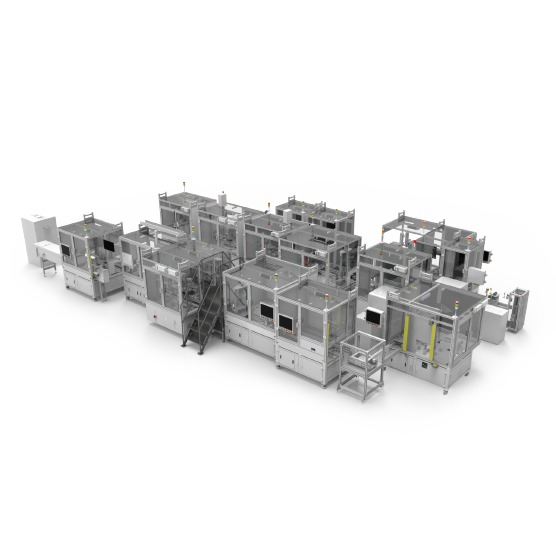

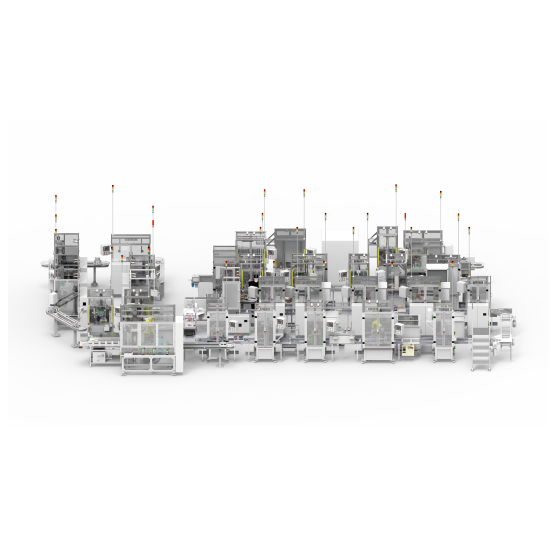

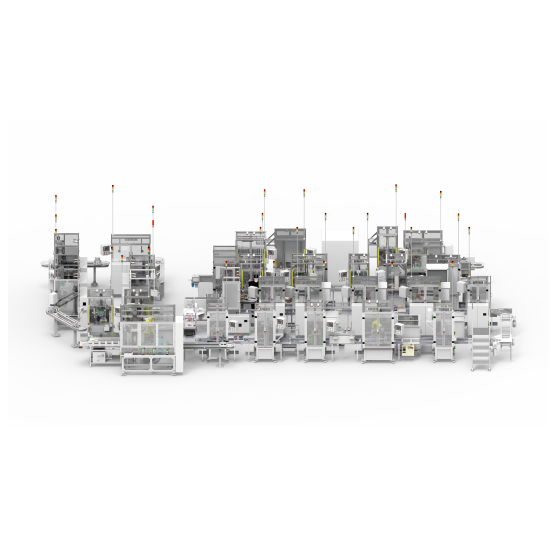

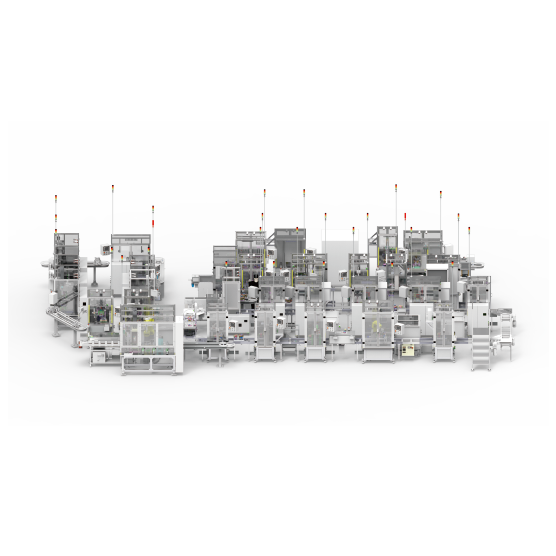

Thermal Management Modules Smart Production Line

Advantages

-

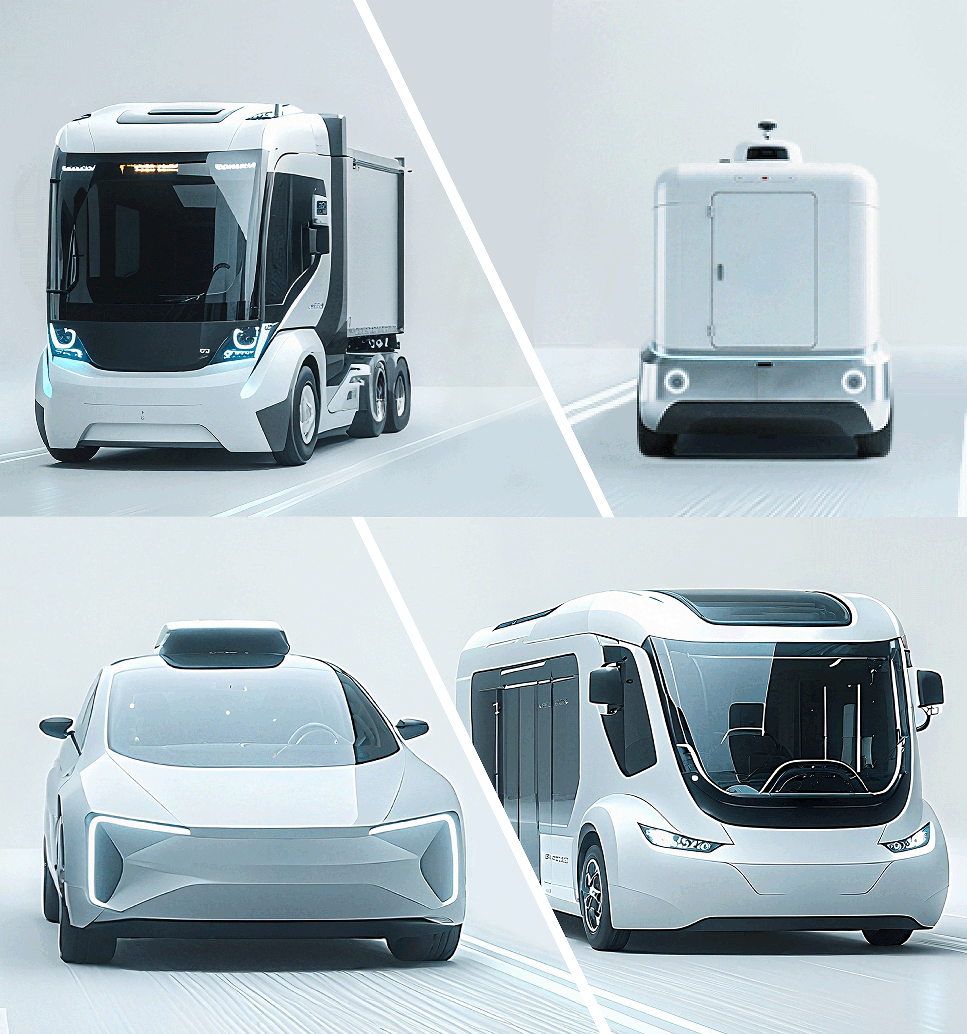

Unmanned Thermal Management

-

High Production Efficiency

-

Intelligent Production Line MES

-

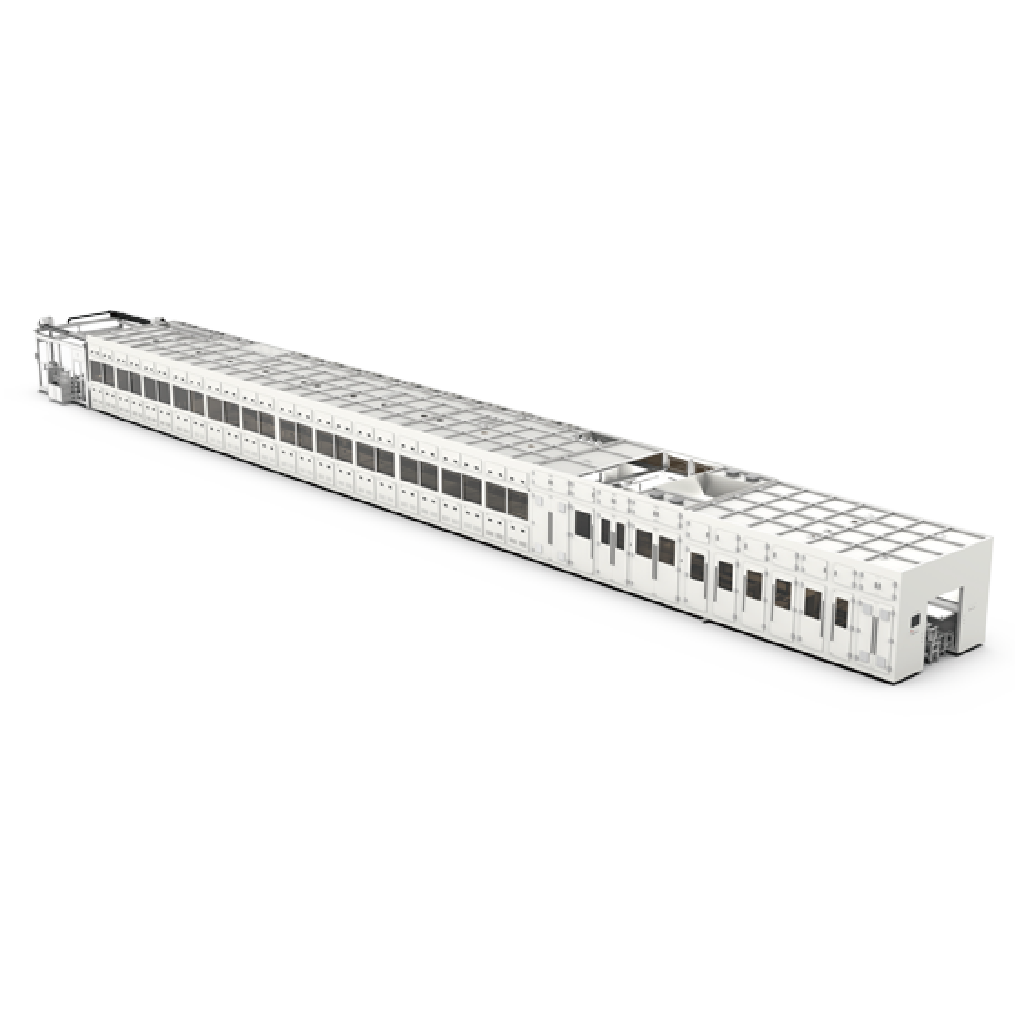

Unmanned Thermal Management

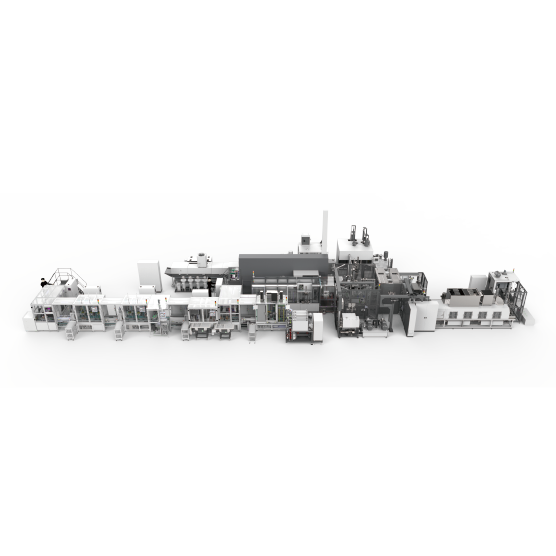

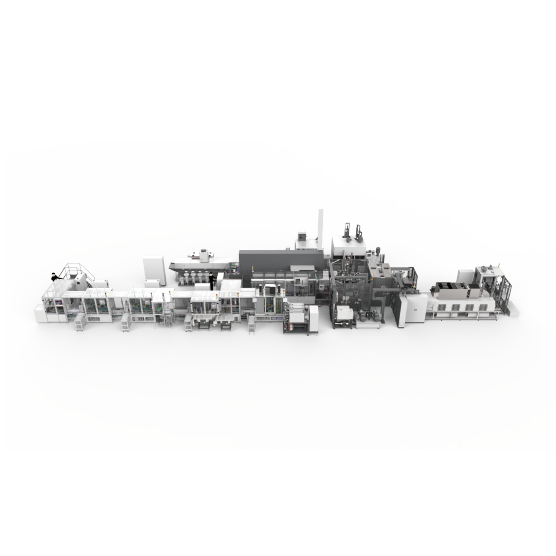

Unmanned Thermal ManagementThe first group to realize fully unmanned thermal management assembly line in the industry, including the water-based systems.

-

High Production Efficiency

High Production EfficiencyLeading in continuous operation duration.

-

Intelligent Production Line MES

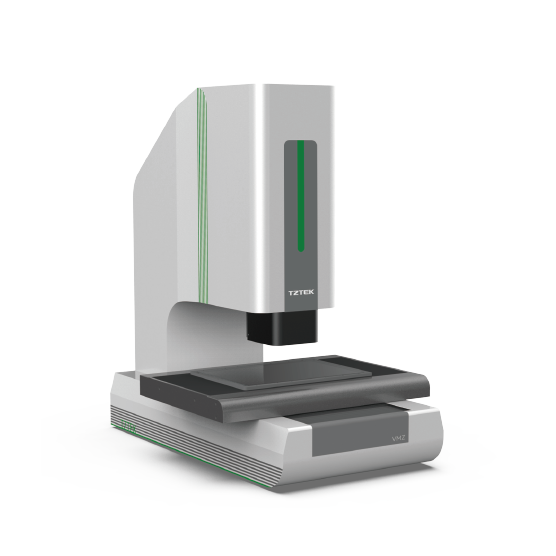

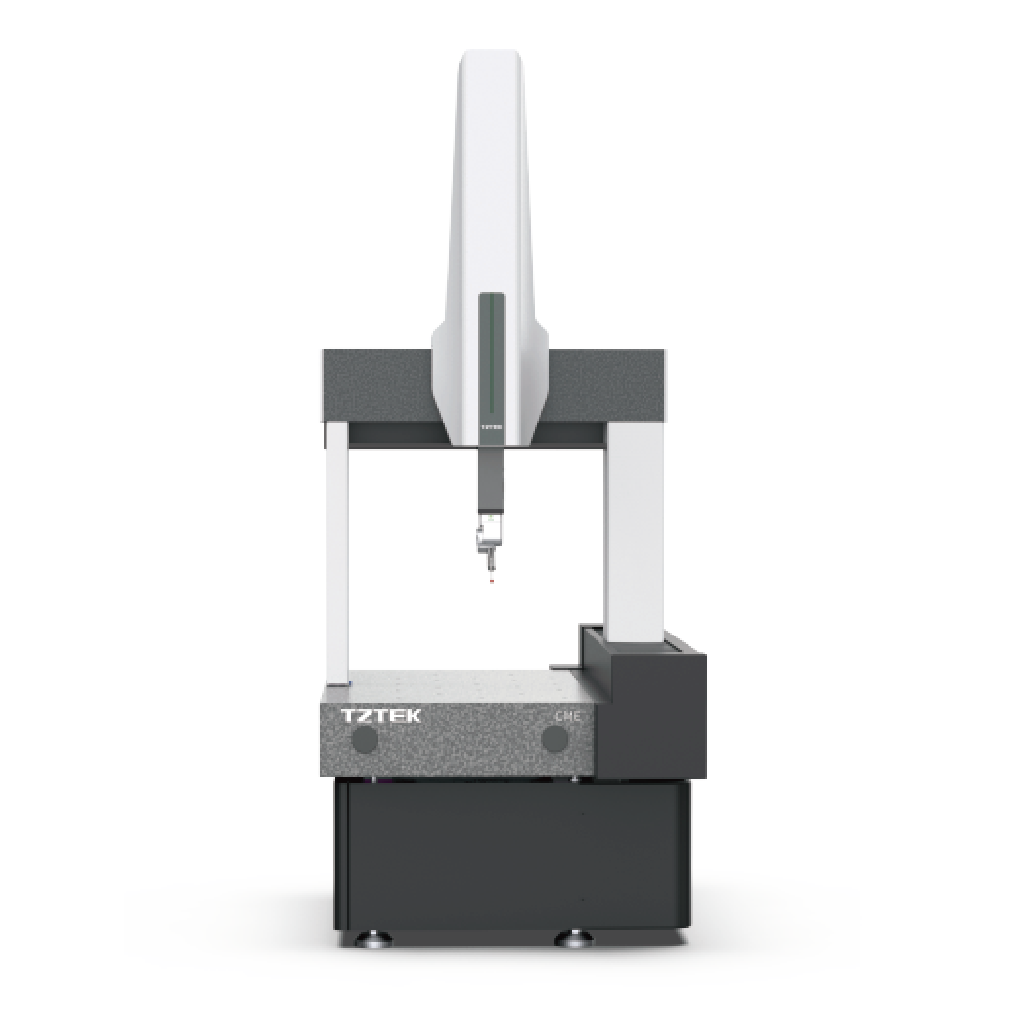

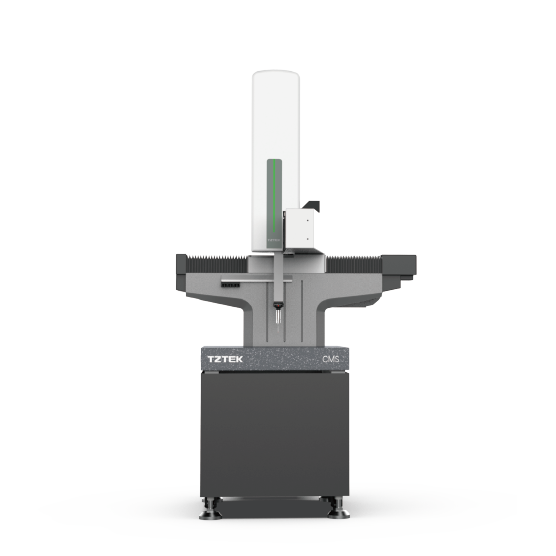

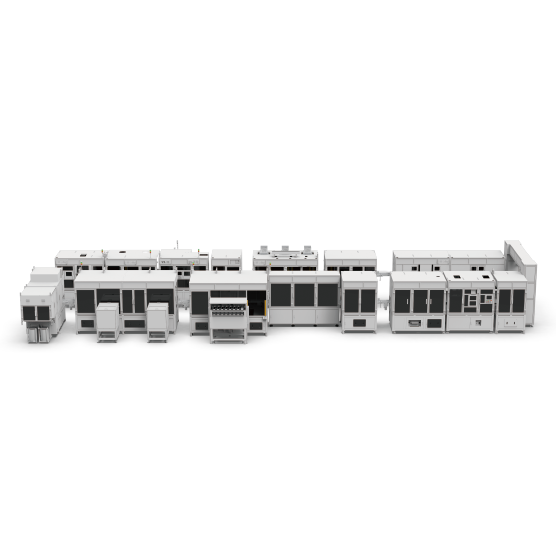

Intelligent Production Line MESMillimeter-level data collection, with intelligent operation and maintenance notifications.

PRODUCT FEATURES

-

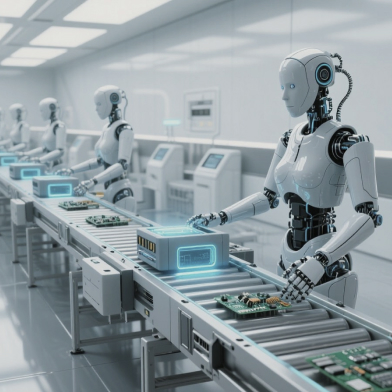

The entire line is designed for operation with fewer than 3 operators, offering high automation. Compared to traditional semi-automatic production lines, it saves over one million yuan in labor costs annually, and inrcreases production capacity to more than 150% of conventional lines, greatly boosting overall efficiency.

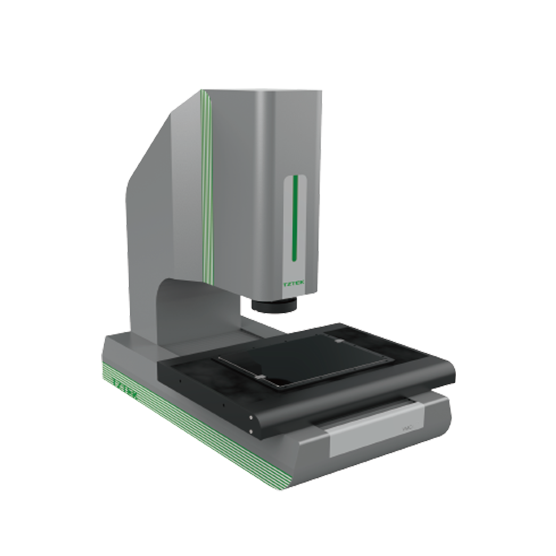

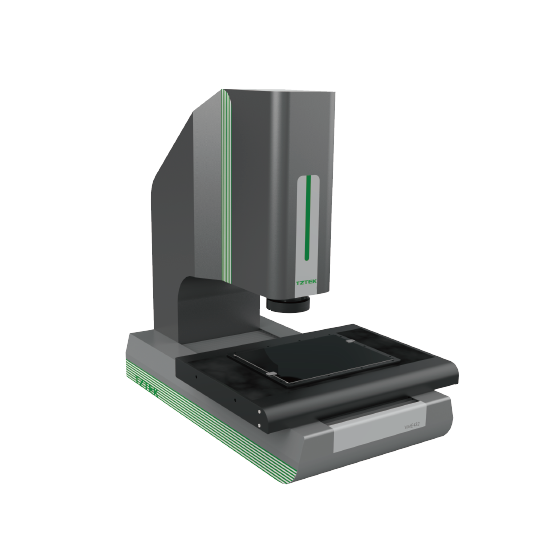

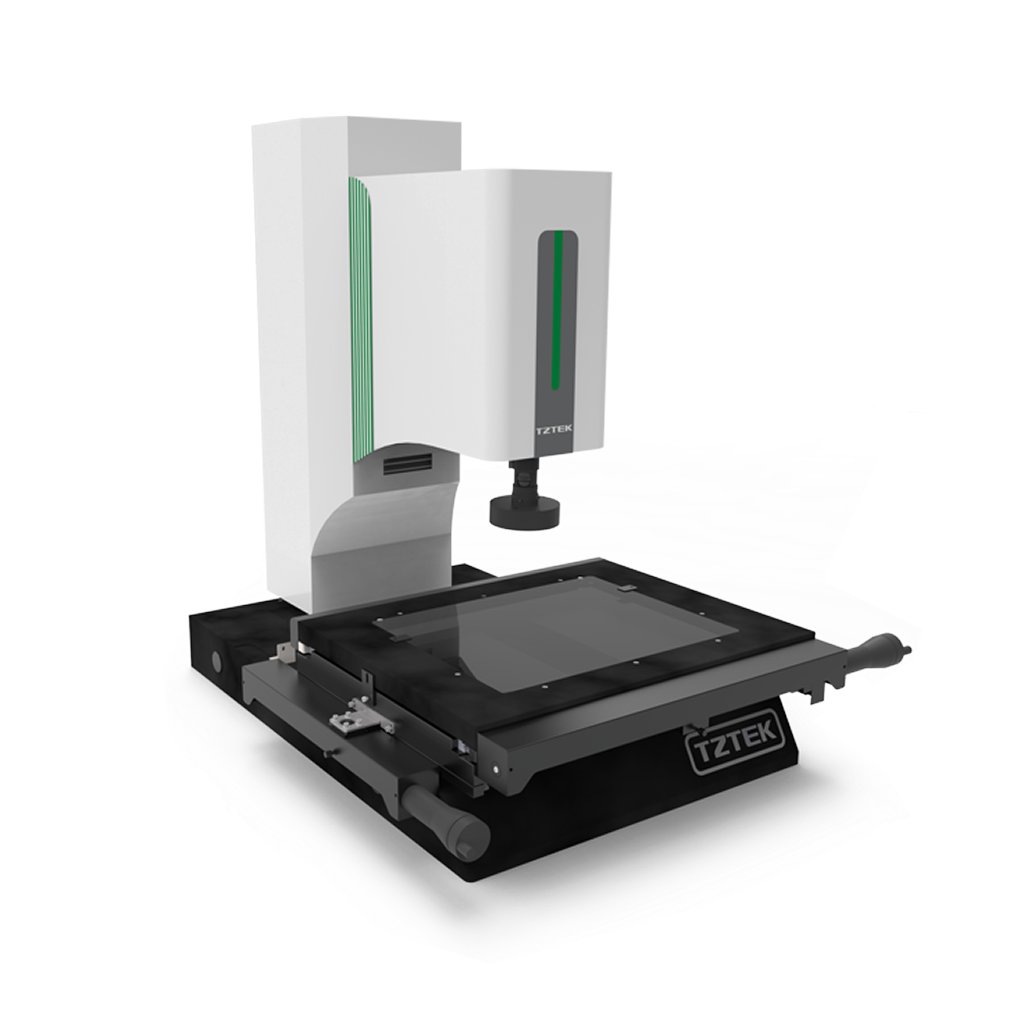

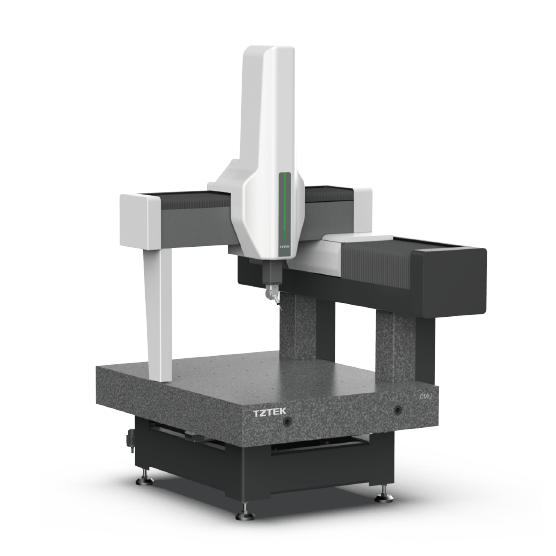

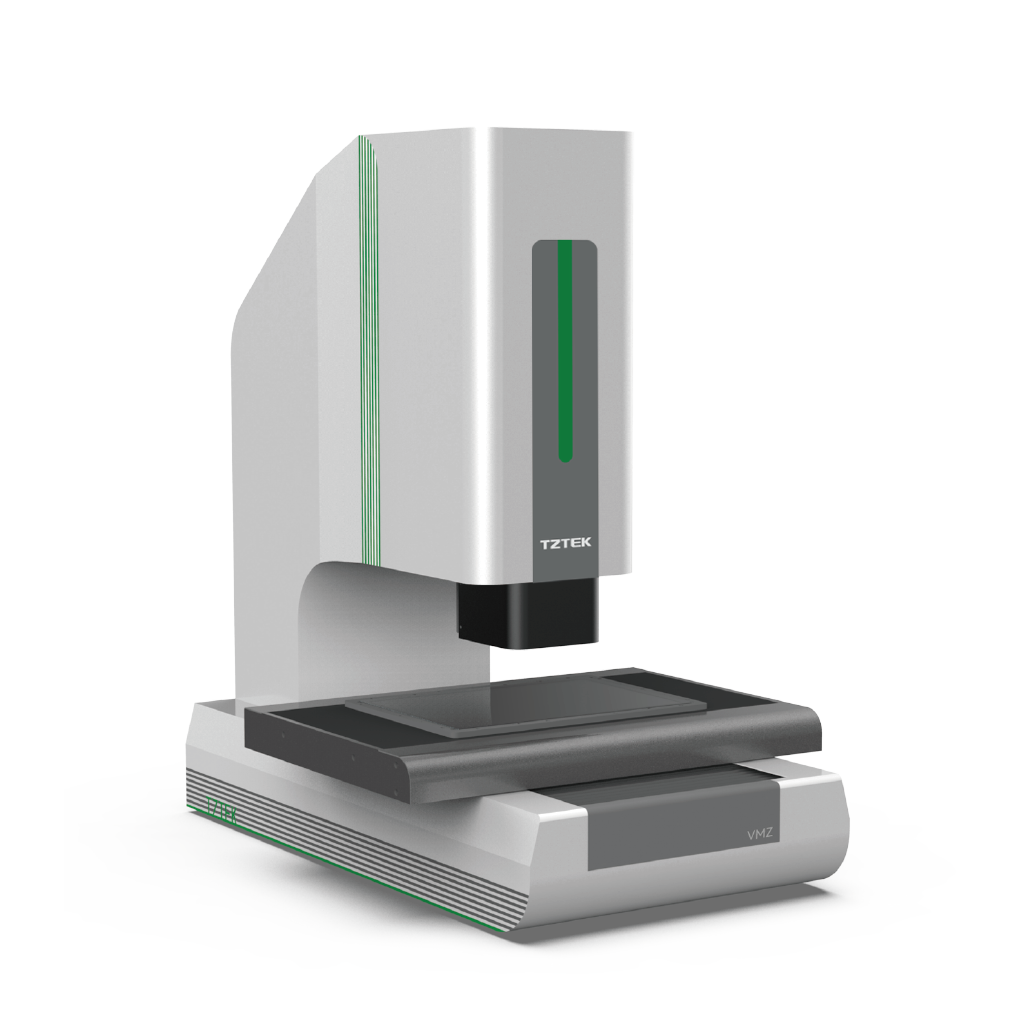

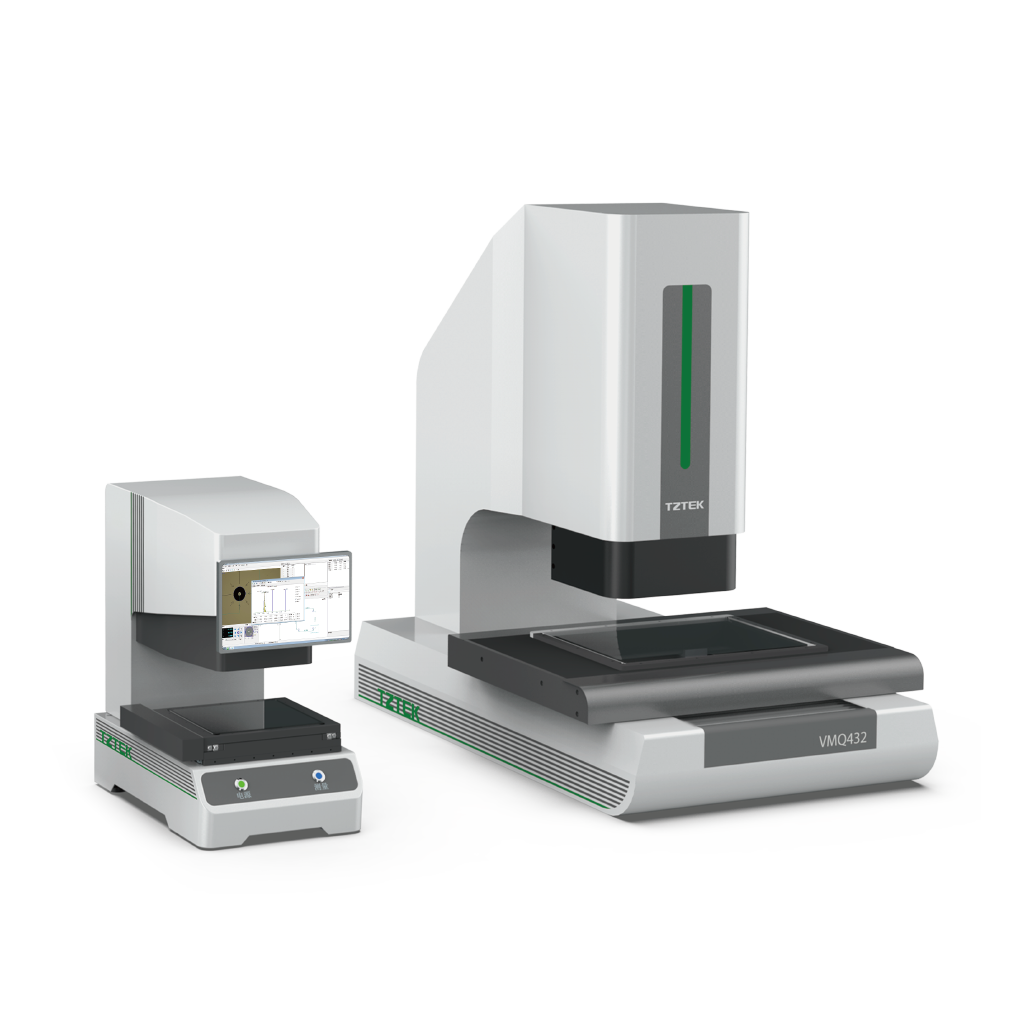

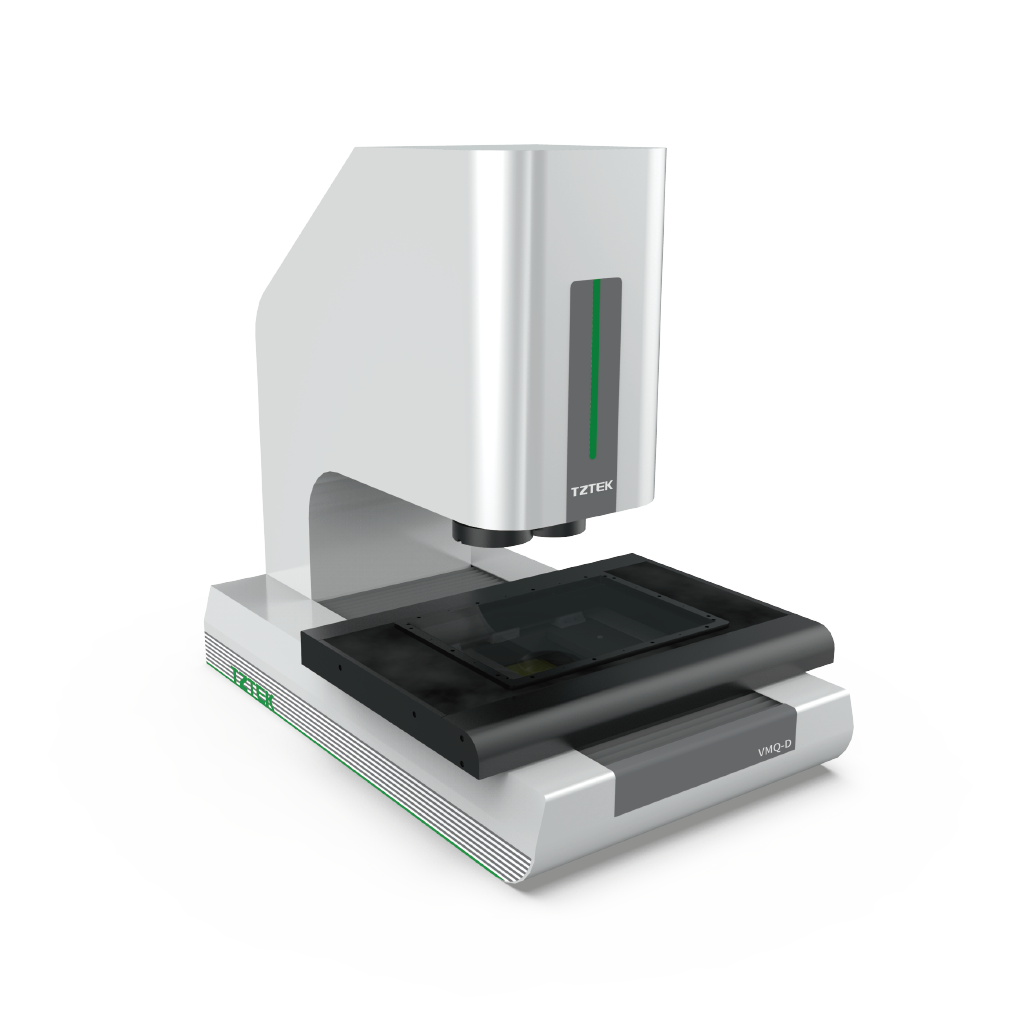

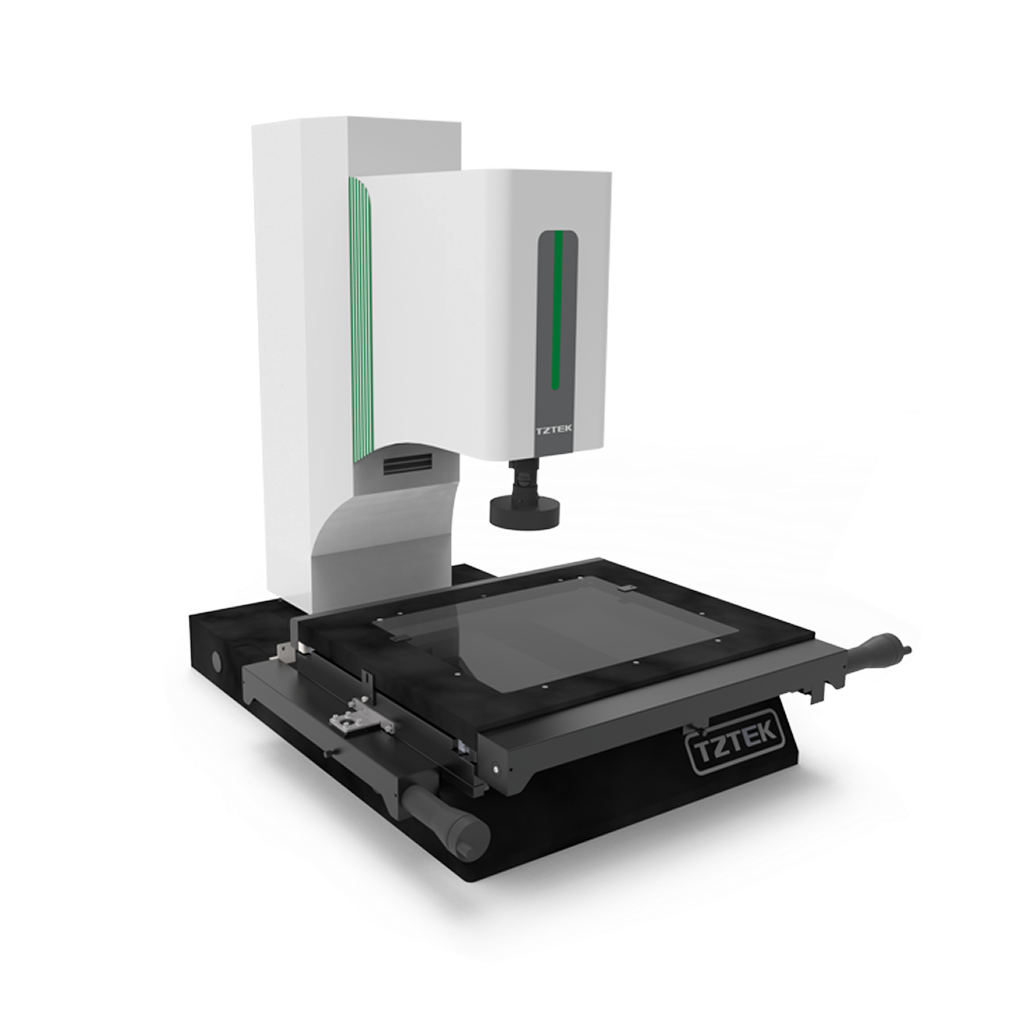

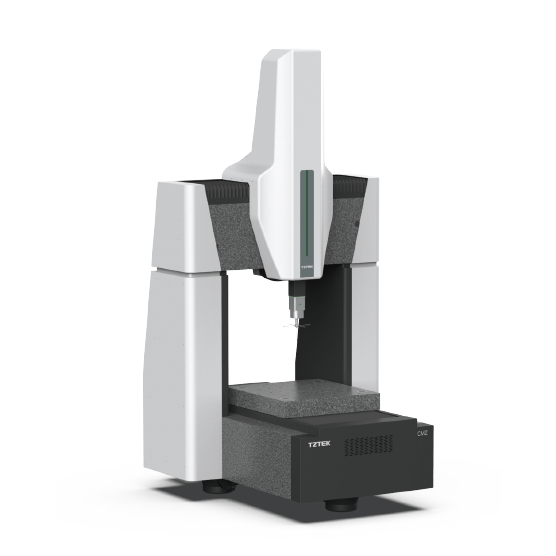

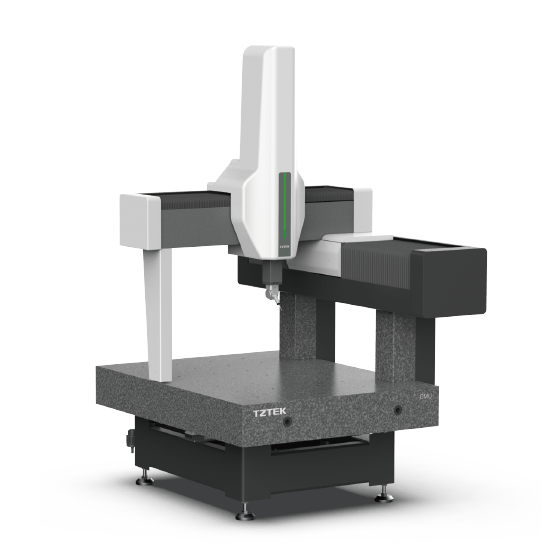

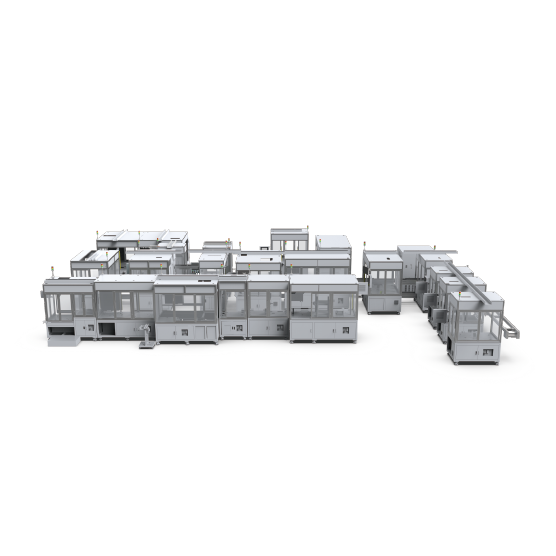

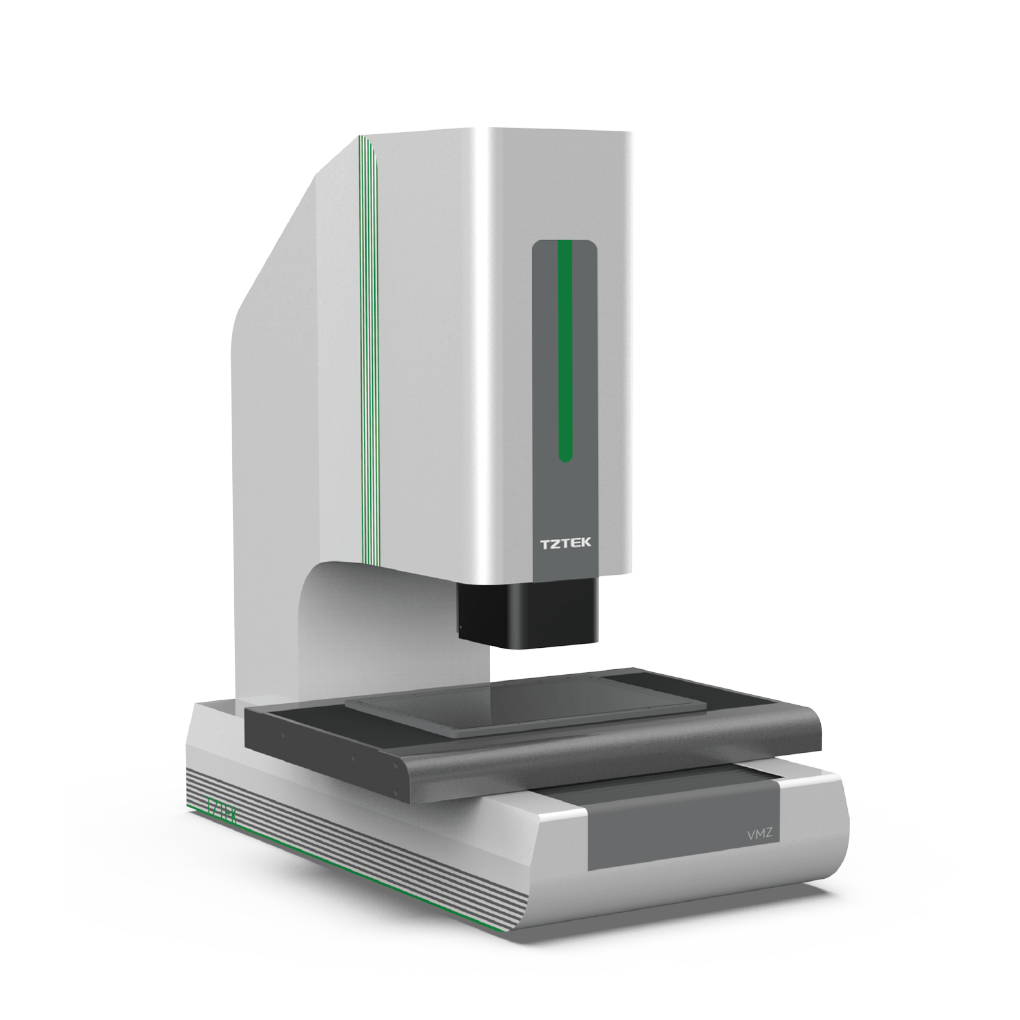

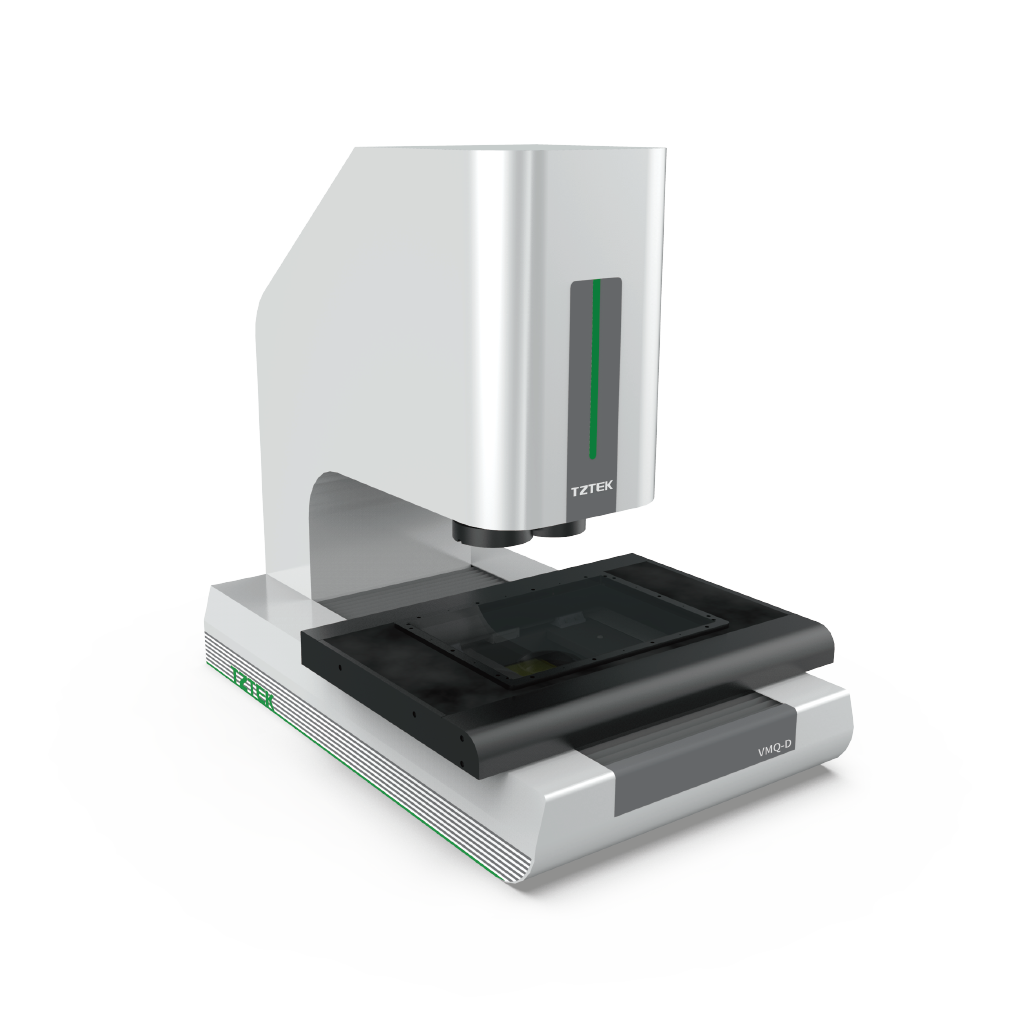

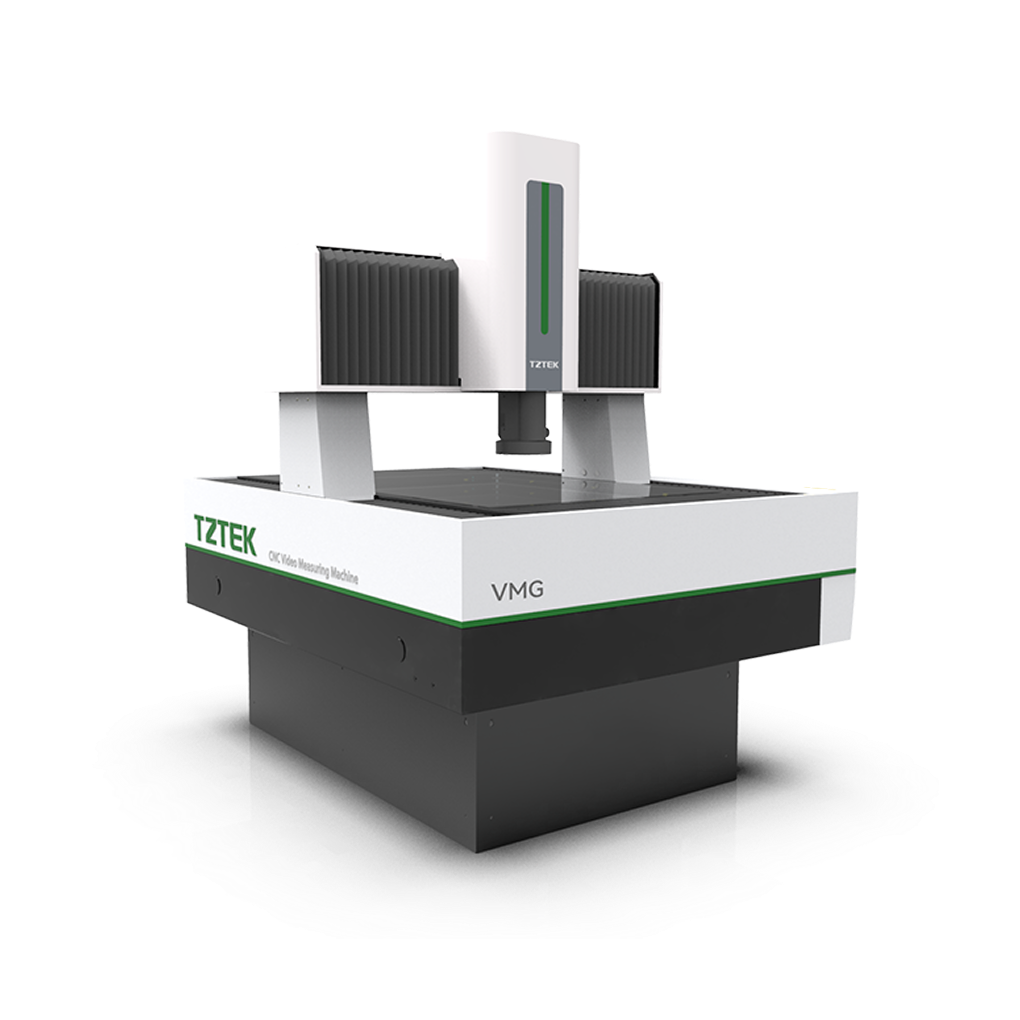

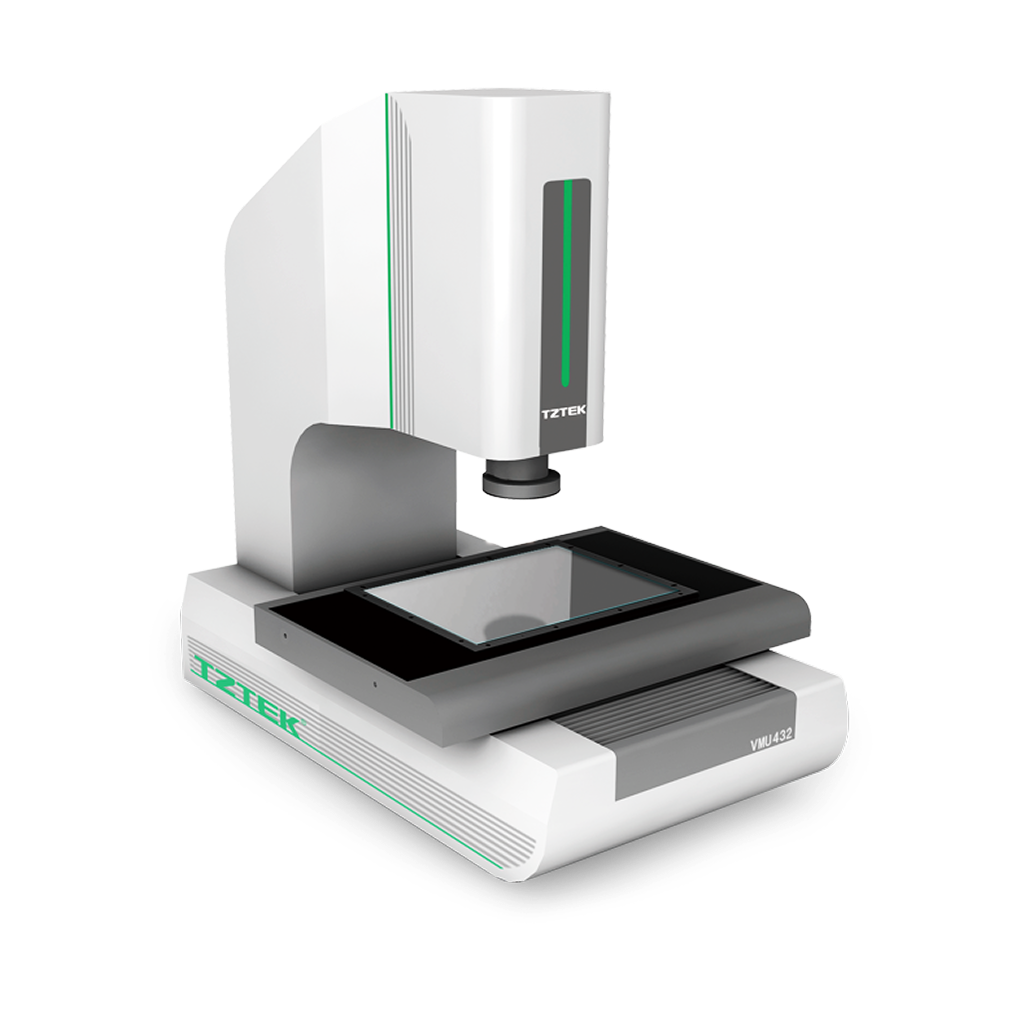

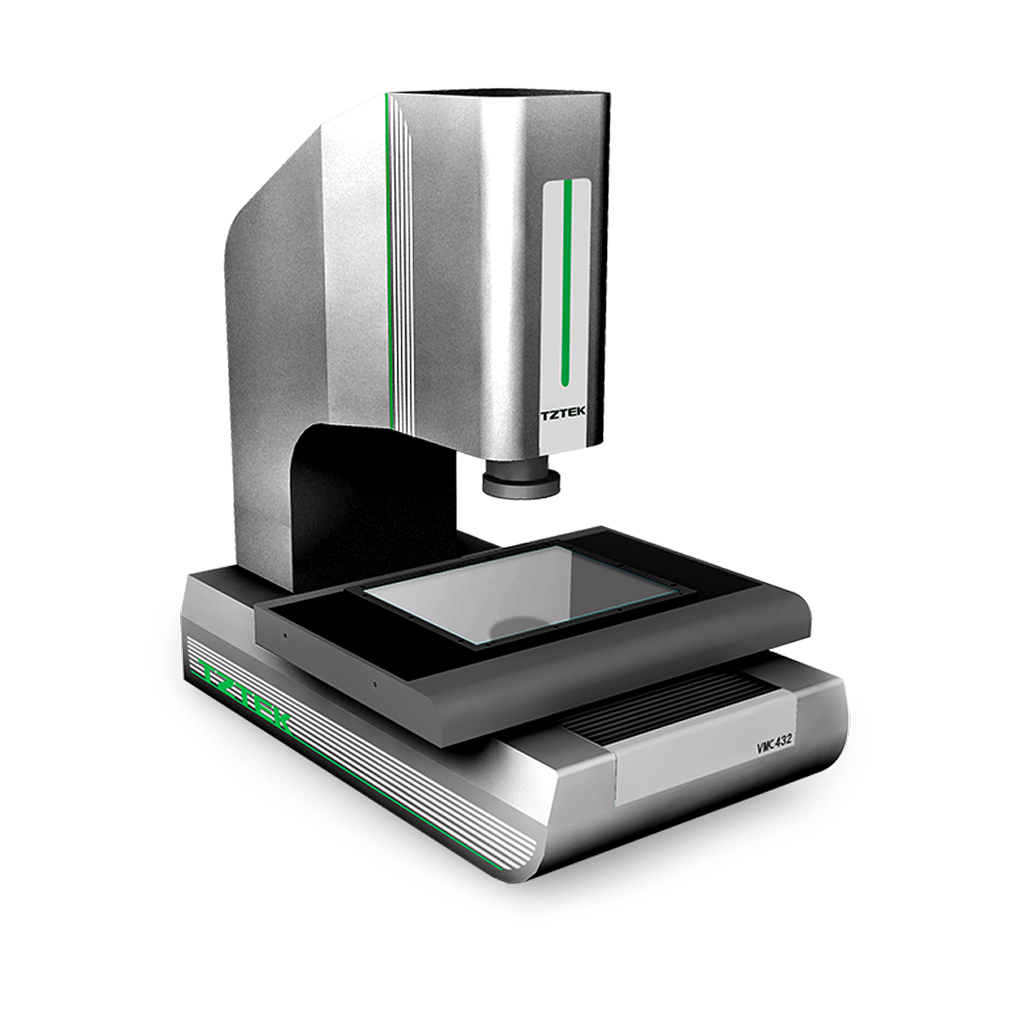

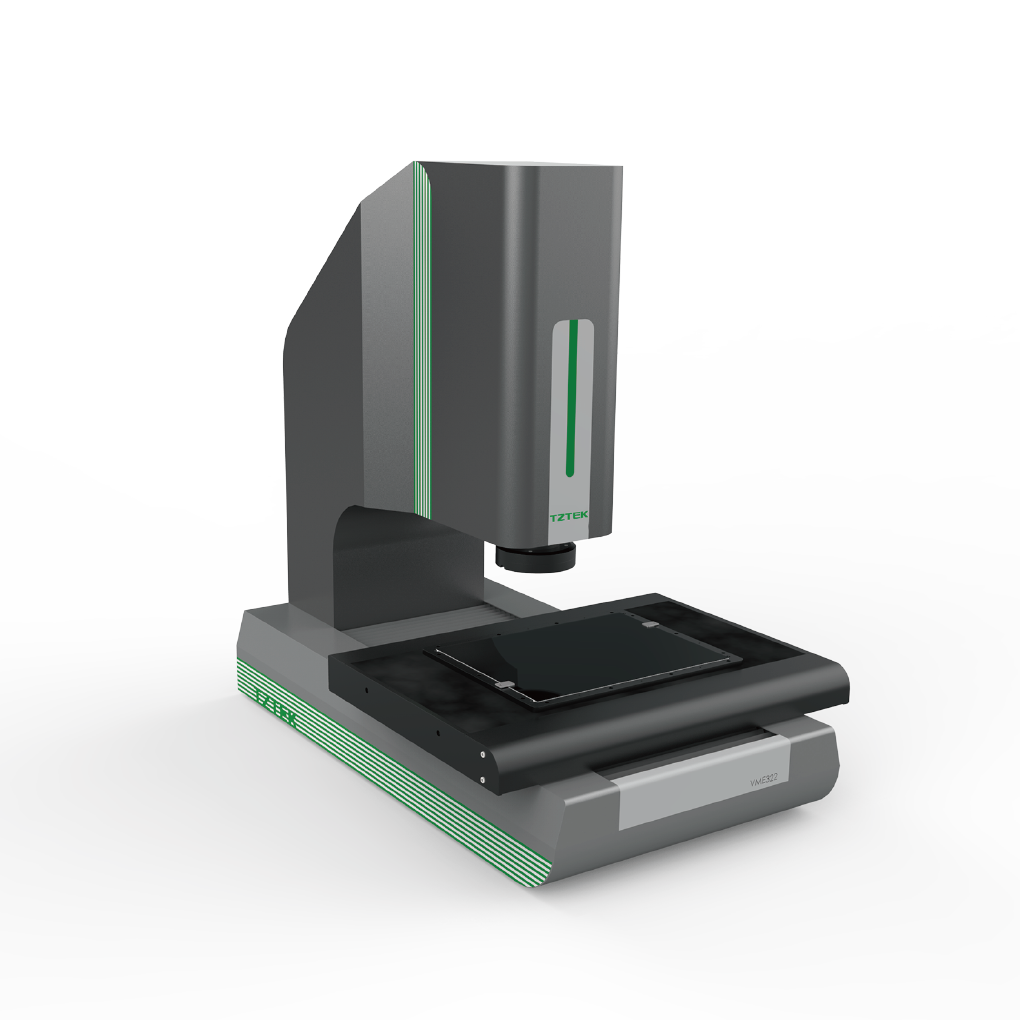

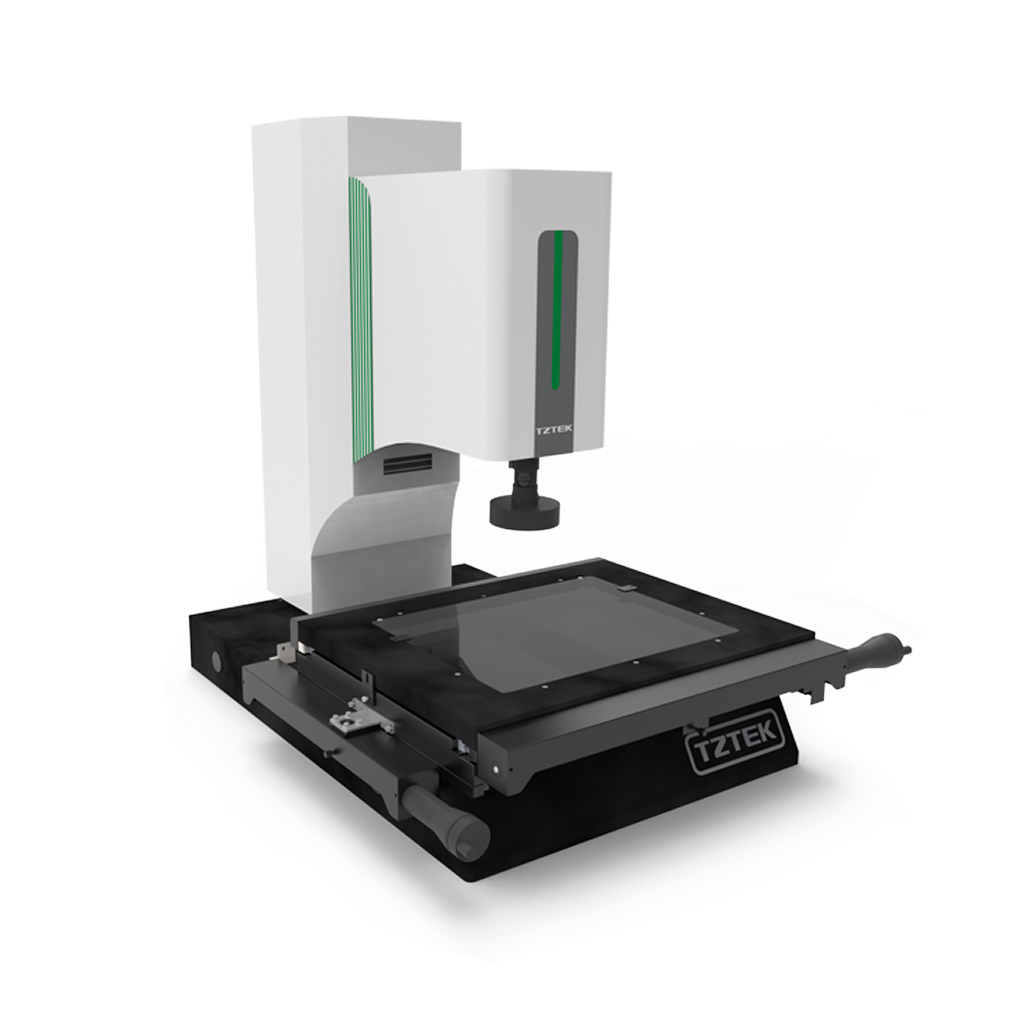

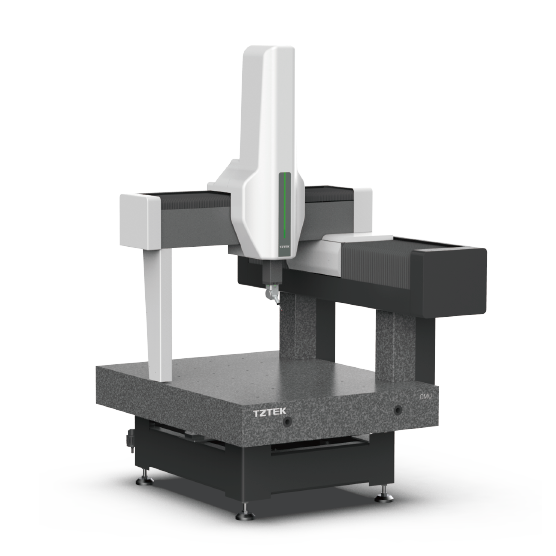

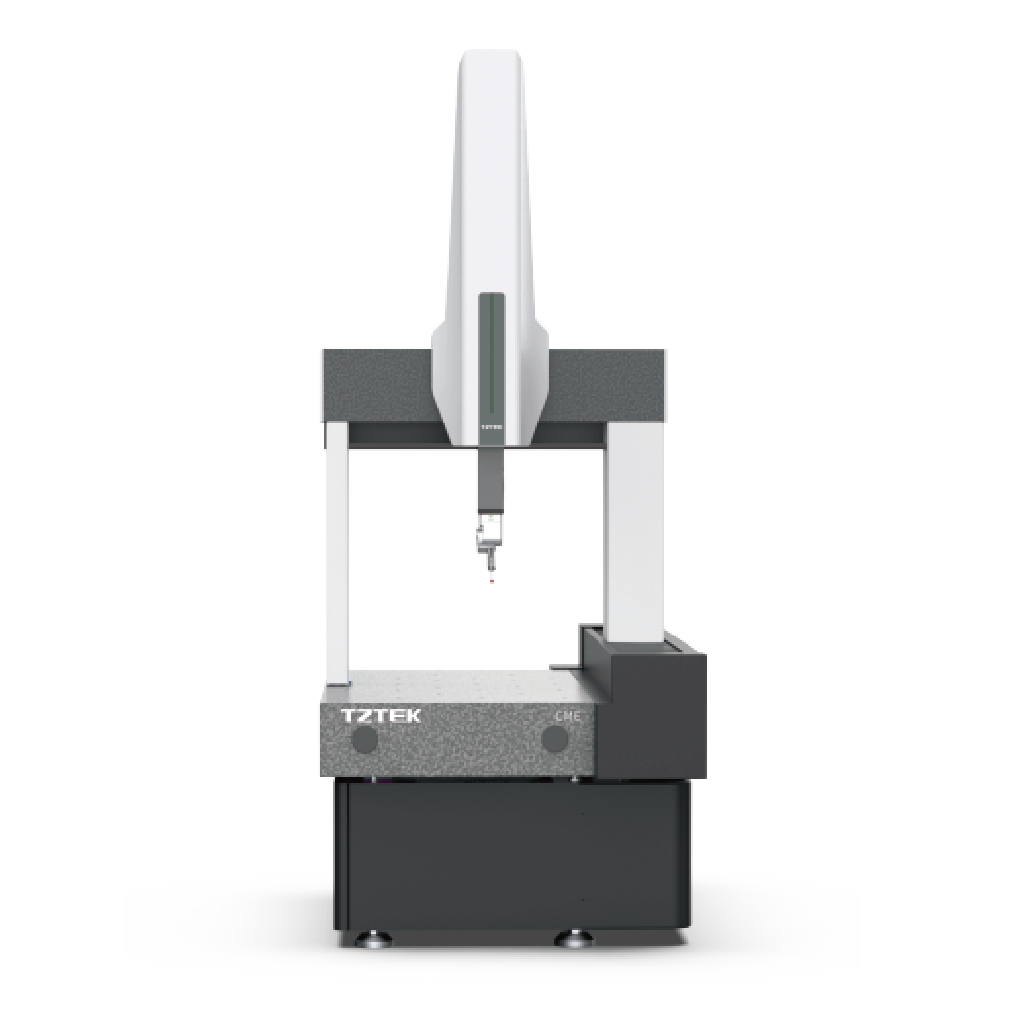

A full range of camera inspections (2D, 3D, line scanning, line laser) ensures comprehensive quality control throughout the production process, from incoming materials to finished products. The combination of visual guidance and robotic arms greatly reduces the assembly defect rate to less than 1%.

Thanks to the high automation design, the entire line enables A-level traceability, which is full-dimensional tracking of OK/NG status for all parts and semi-finished products, including raw materials.