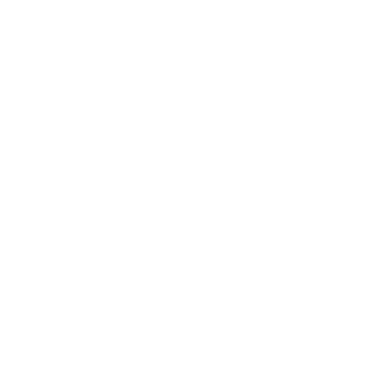

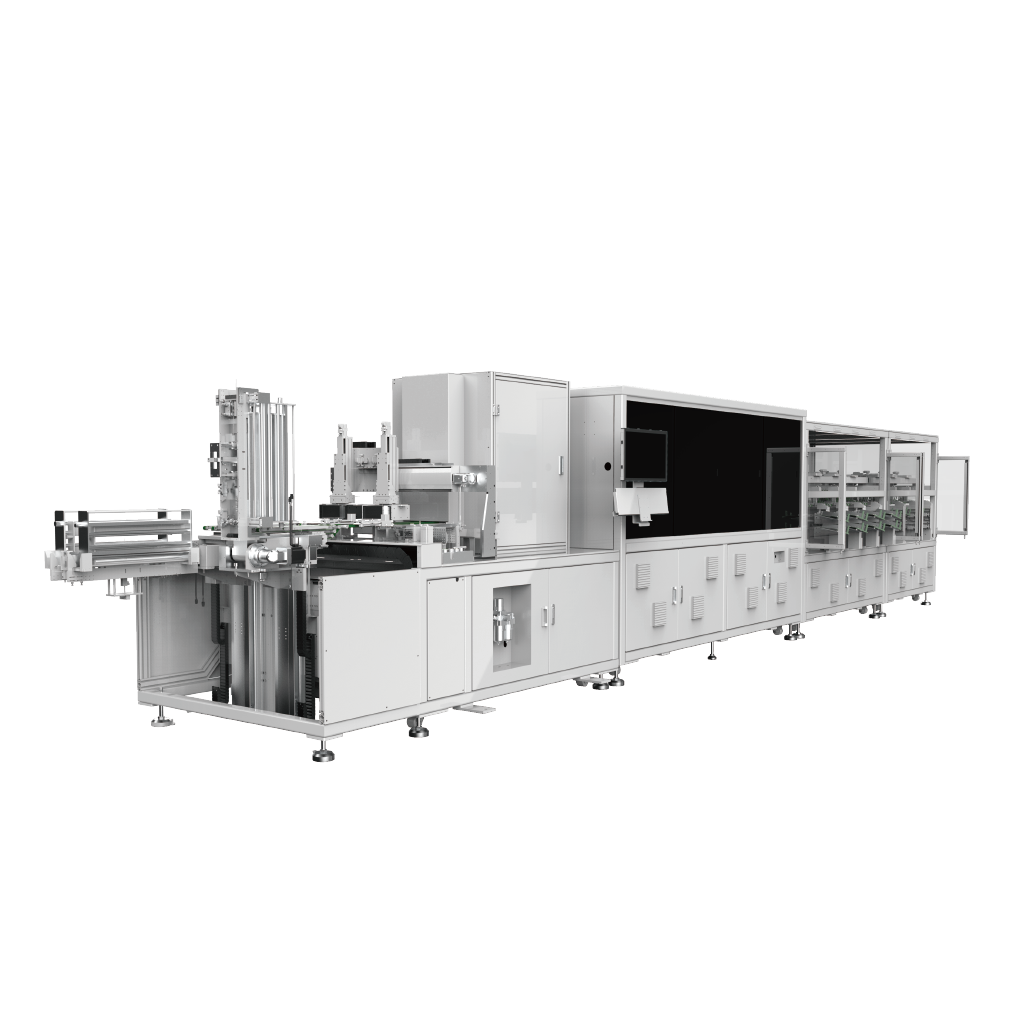

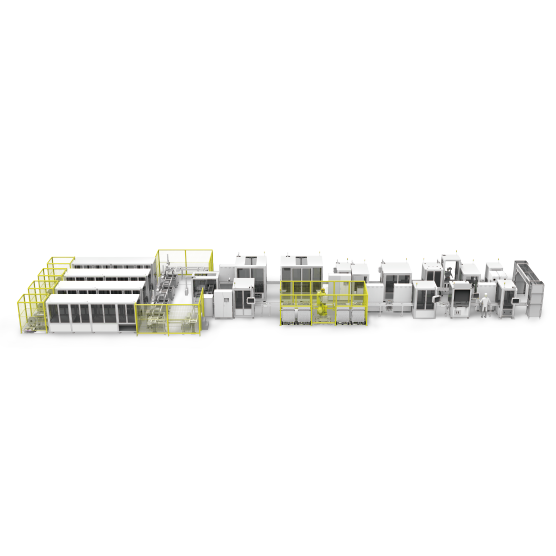

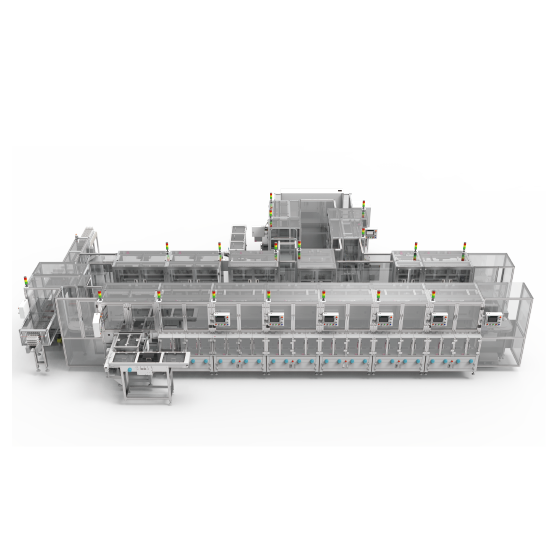

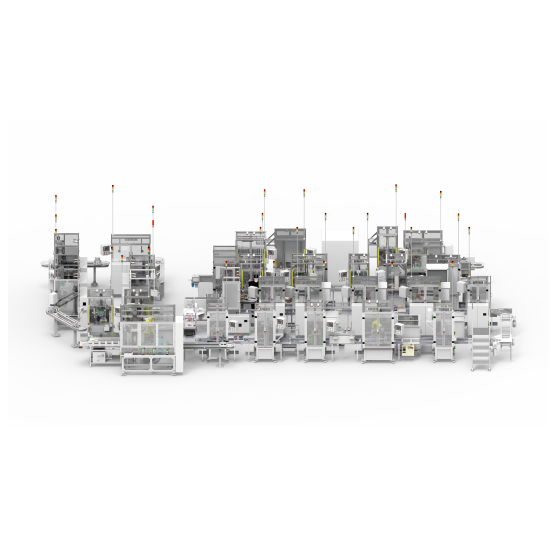

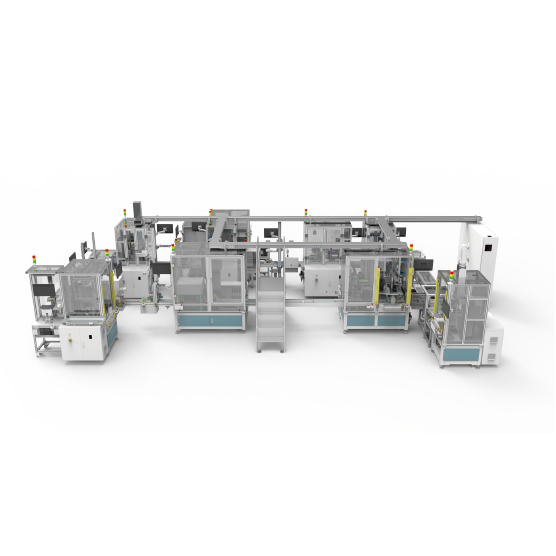

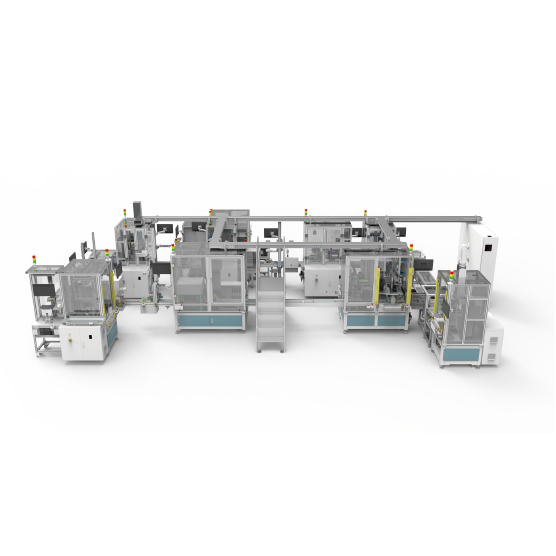

Electronic Water Pumps Smart Production Line

Advantages

-

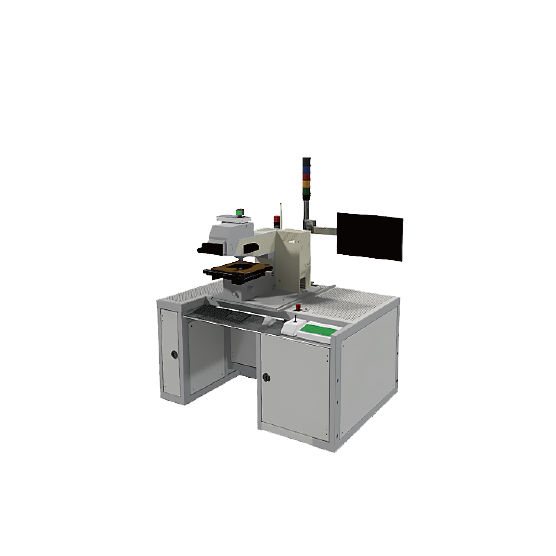

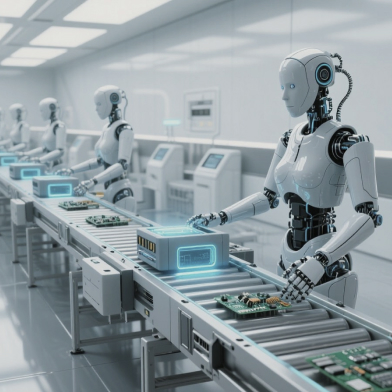

Fully automated, unmanned production

-

High Assembly Yield Rate

-

Production Cycle

-

Full-process data traceability system

-

Fully automated, unmanned production

Fully automated, unmanned productionReduces labor costs, boosts production efficiency, and ensures consistent product quality across factories.

-

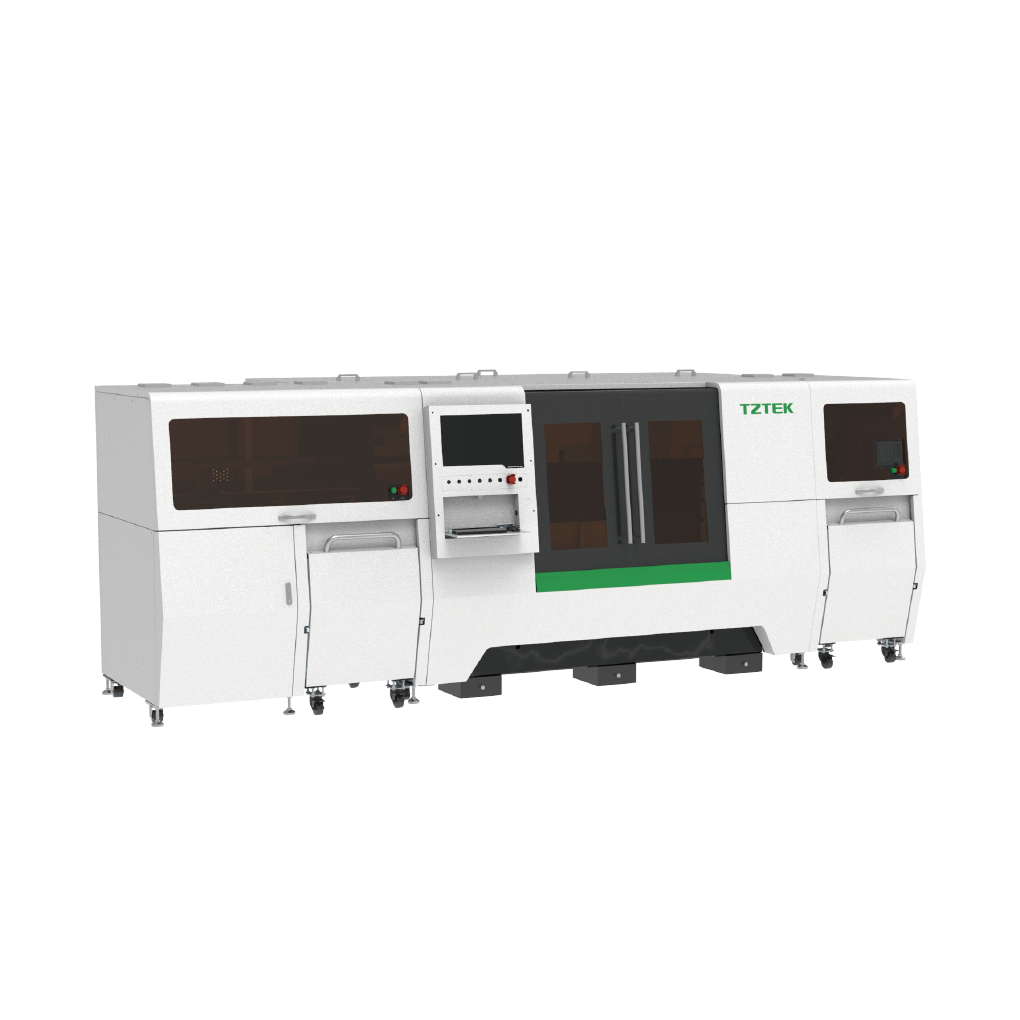

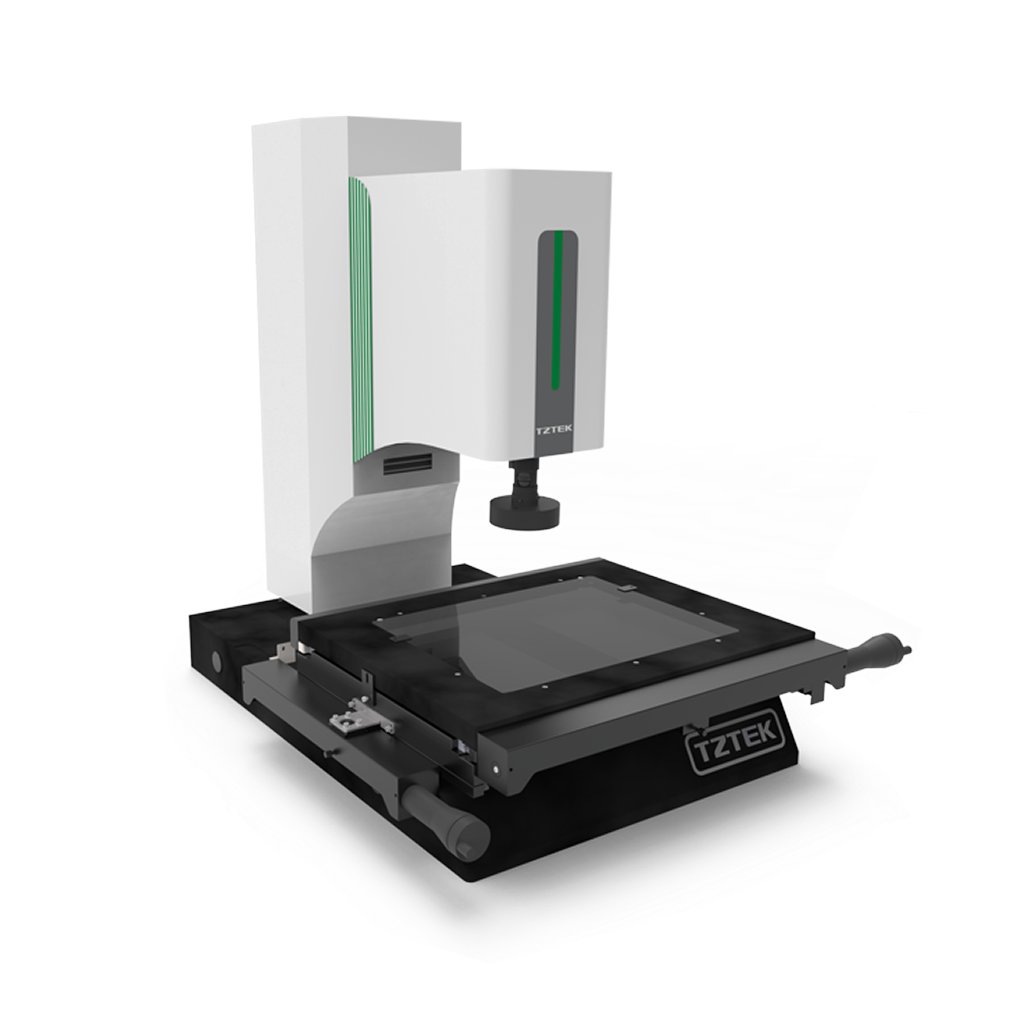

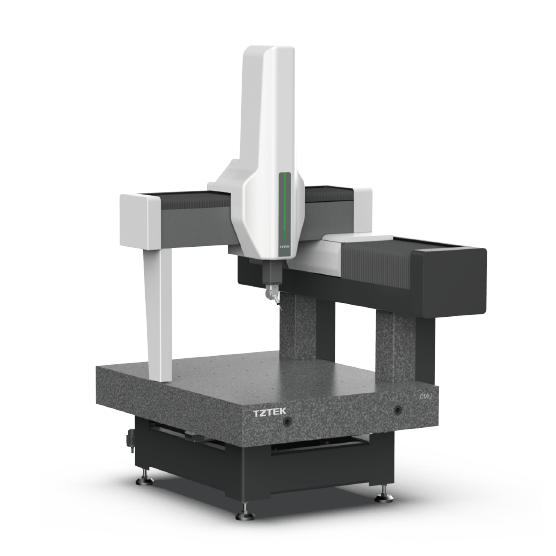

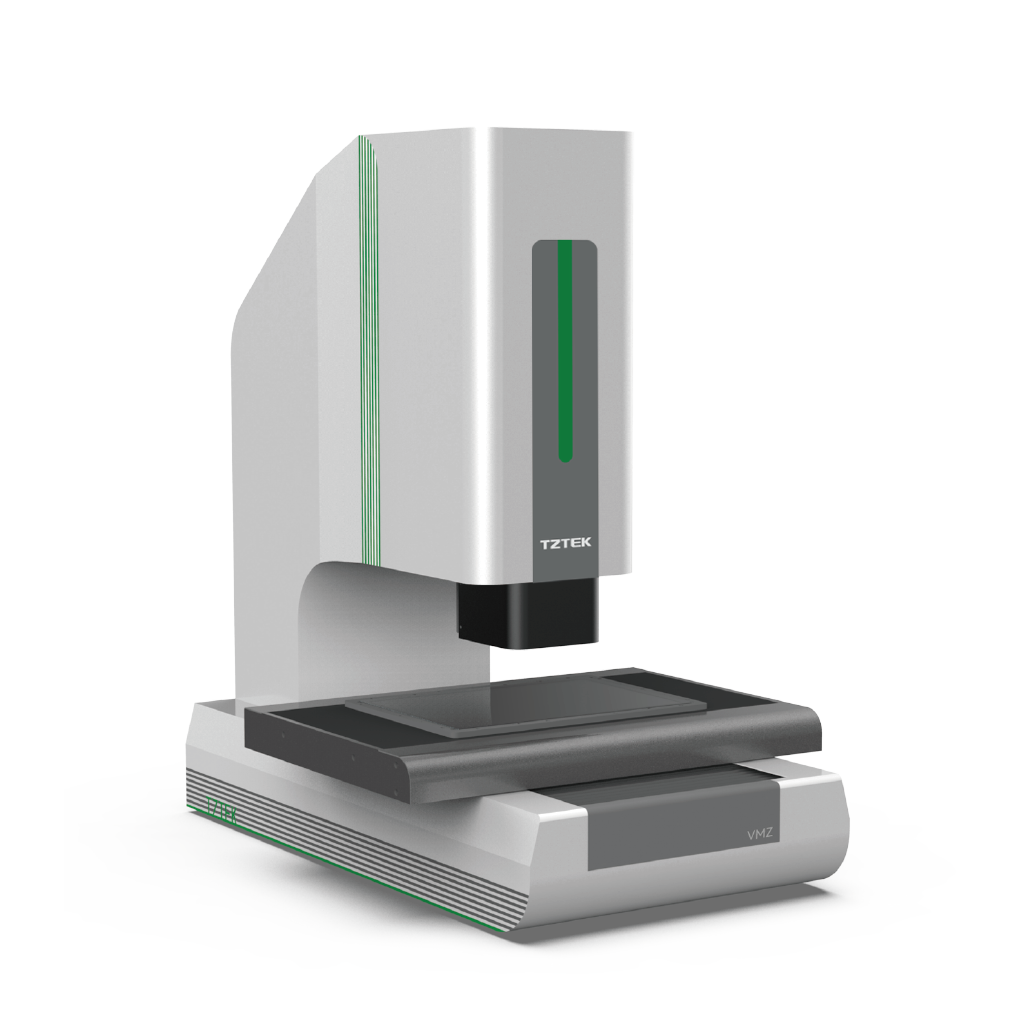

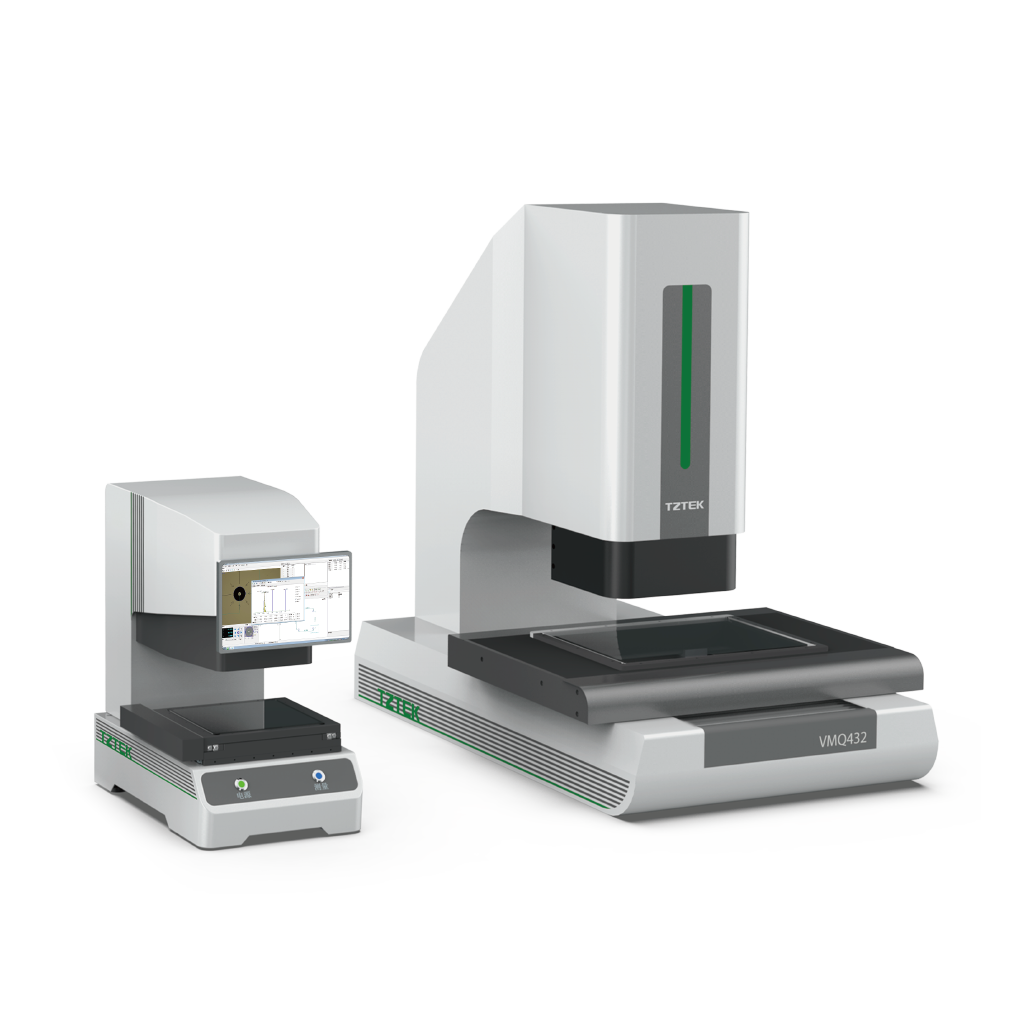

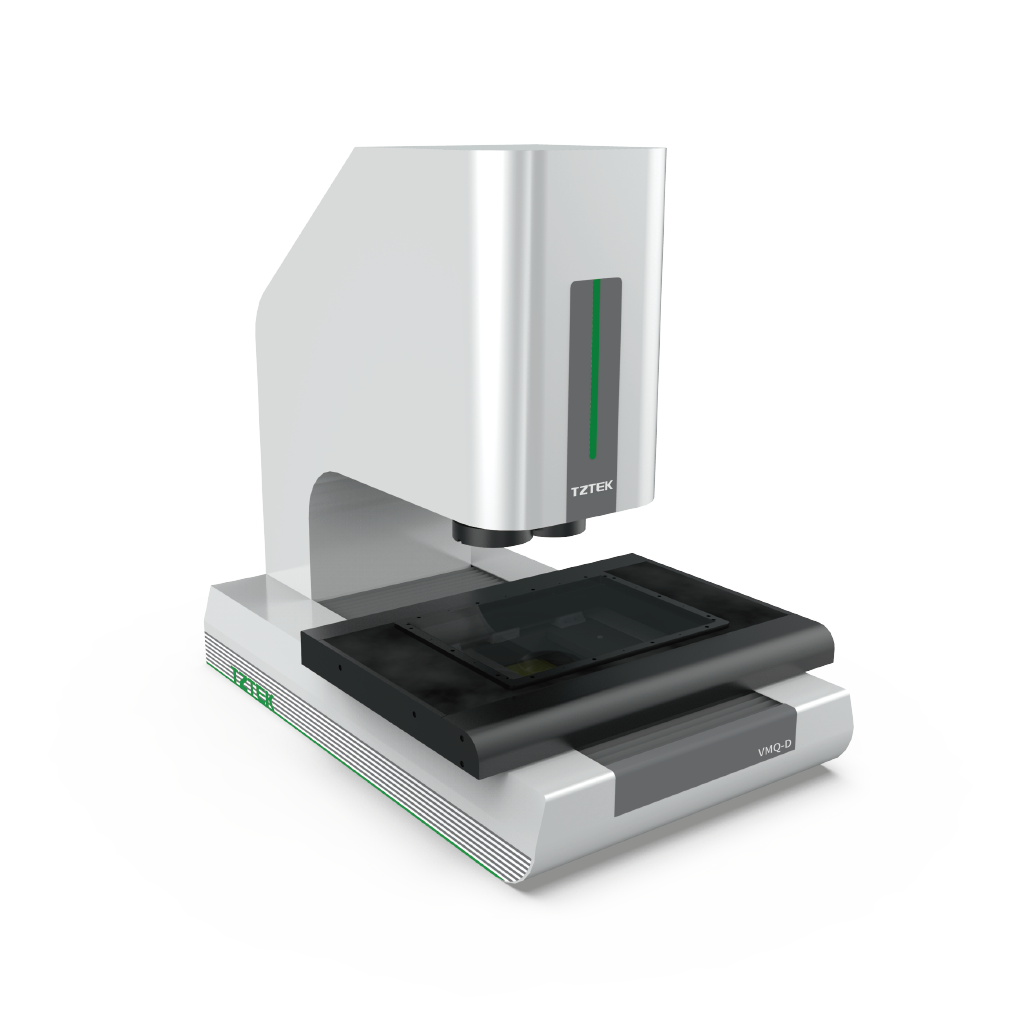

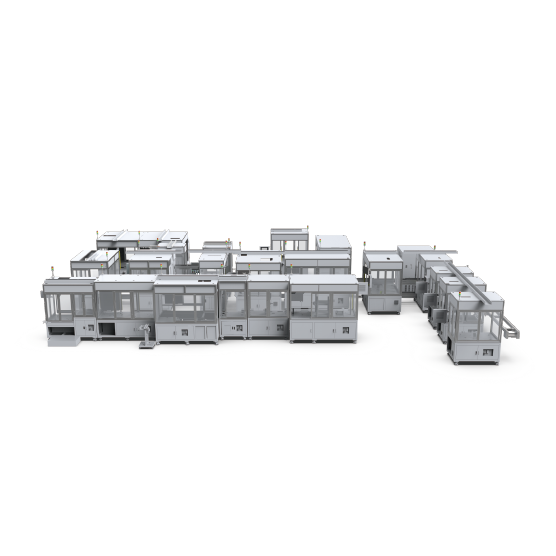

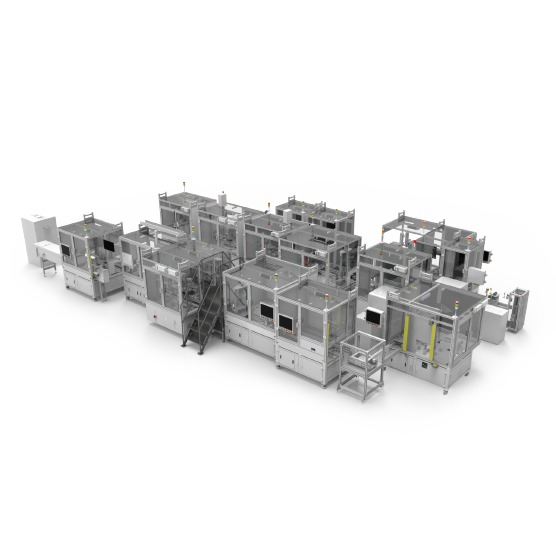

High Assembly Yield Rate

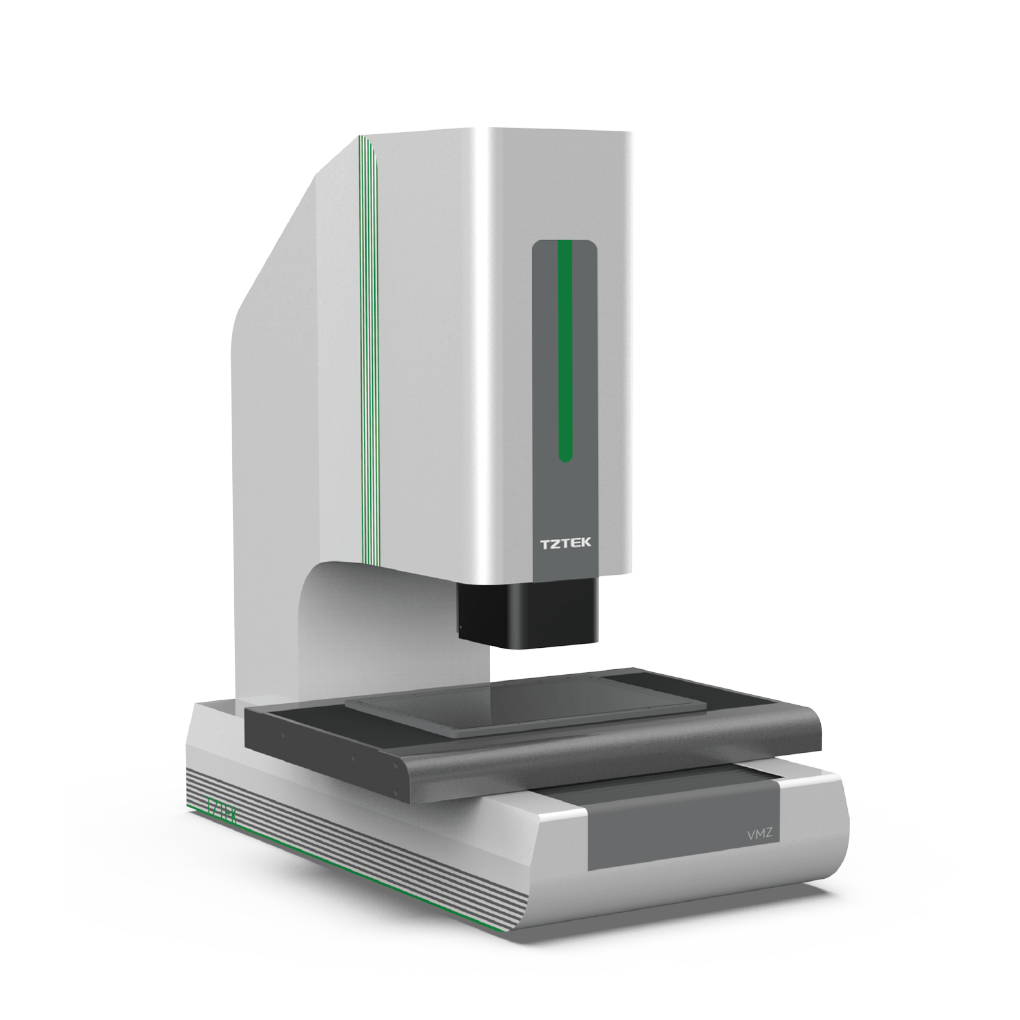

High Assembly Yield RateBy using visual systems, sensors, and standard measurement tools, the entire production process— from incoming materials to finished goods— is monitored, achieving an assembly yield rate of ≥99%

-

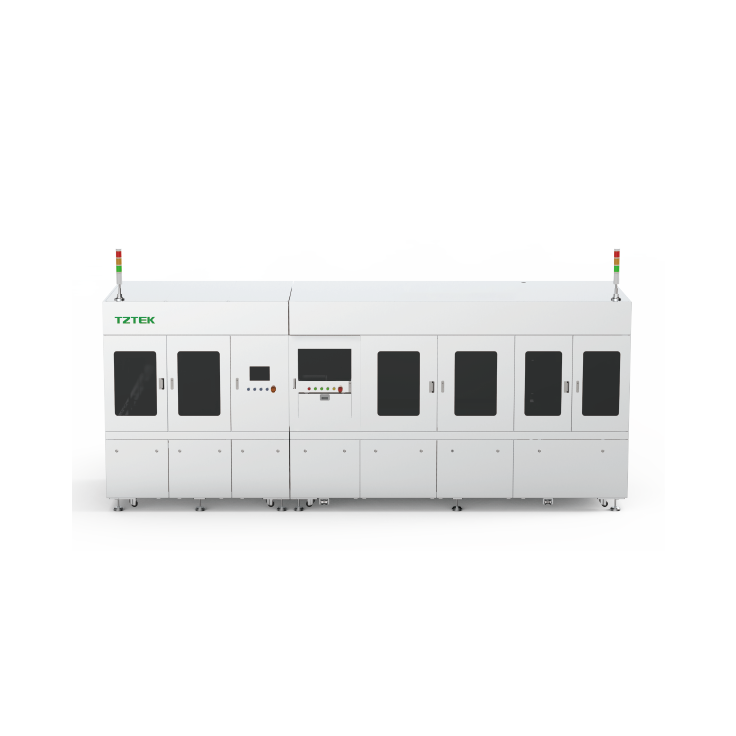

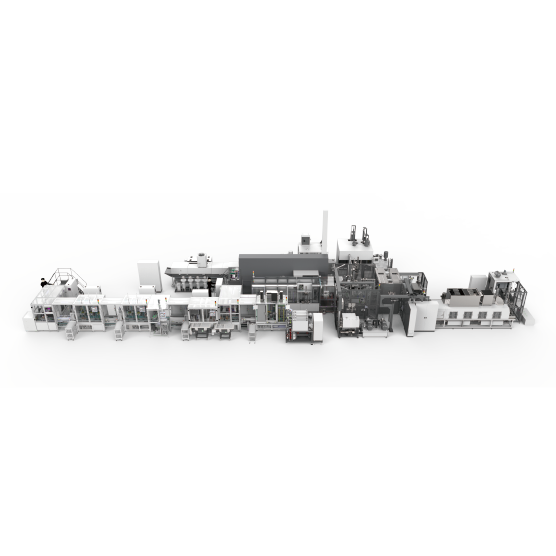

Production Cycle

Production Cycle15 seconds per piece, enabling the production of 4,800 electronic water pumps per day, and 1.7 million units annually.

-

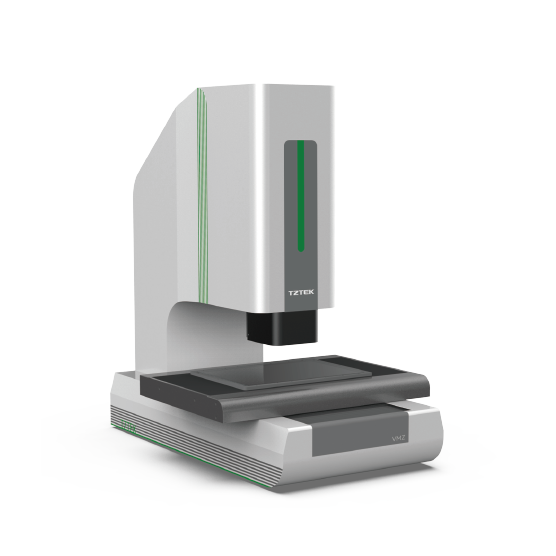

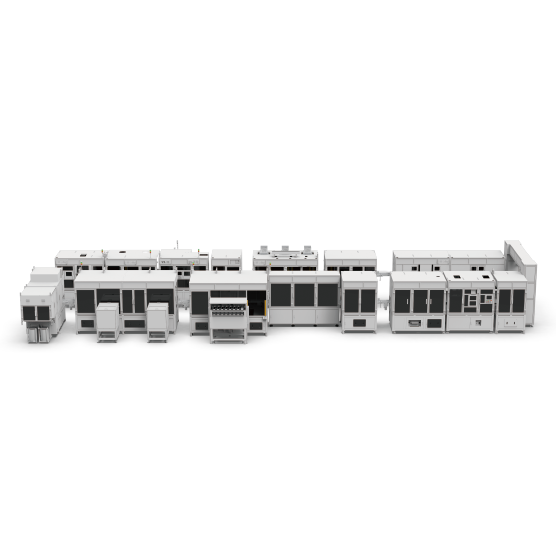

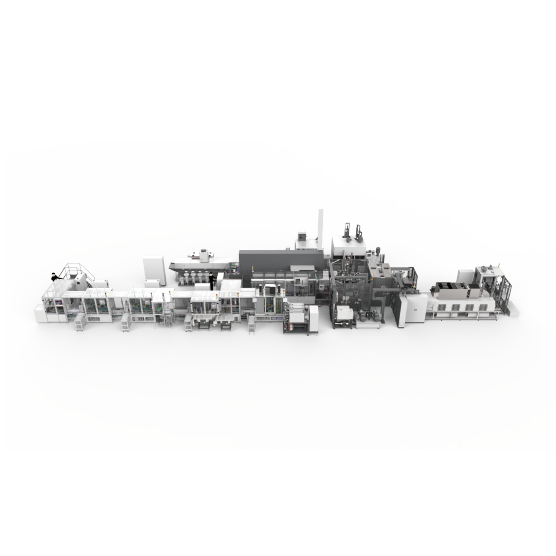

Full-process data traceability system

Full-process data traceability systemProvides real-time online monitoring of both product production and the production line's status, ensuring traceability of quality data throughout assembly, inspection, and production processes, while optimizing line efficiency.