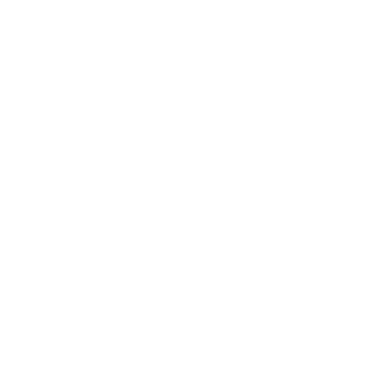

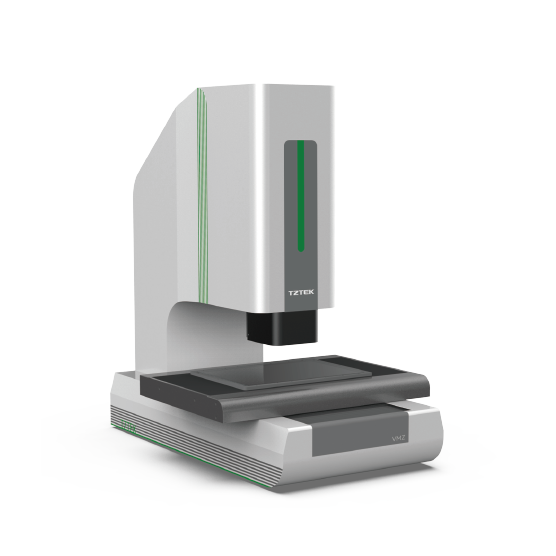

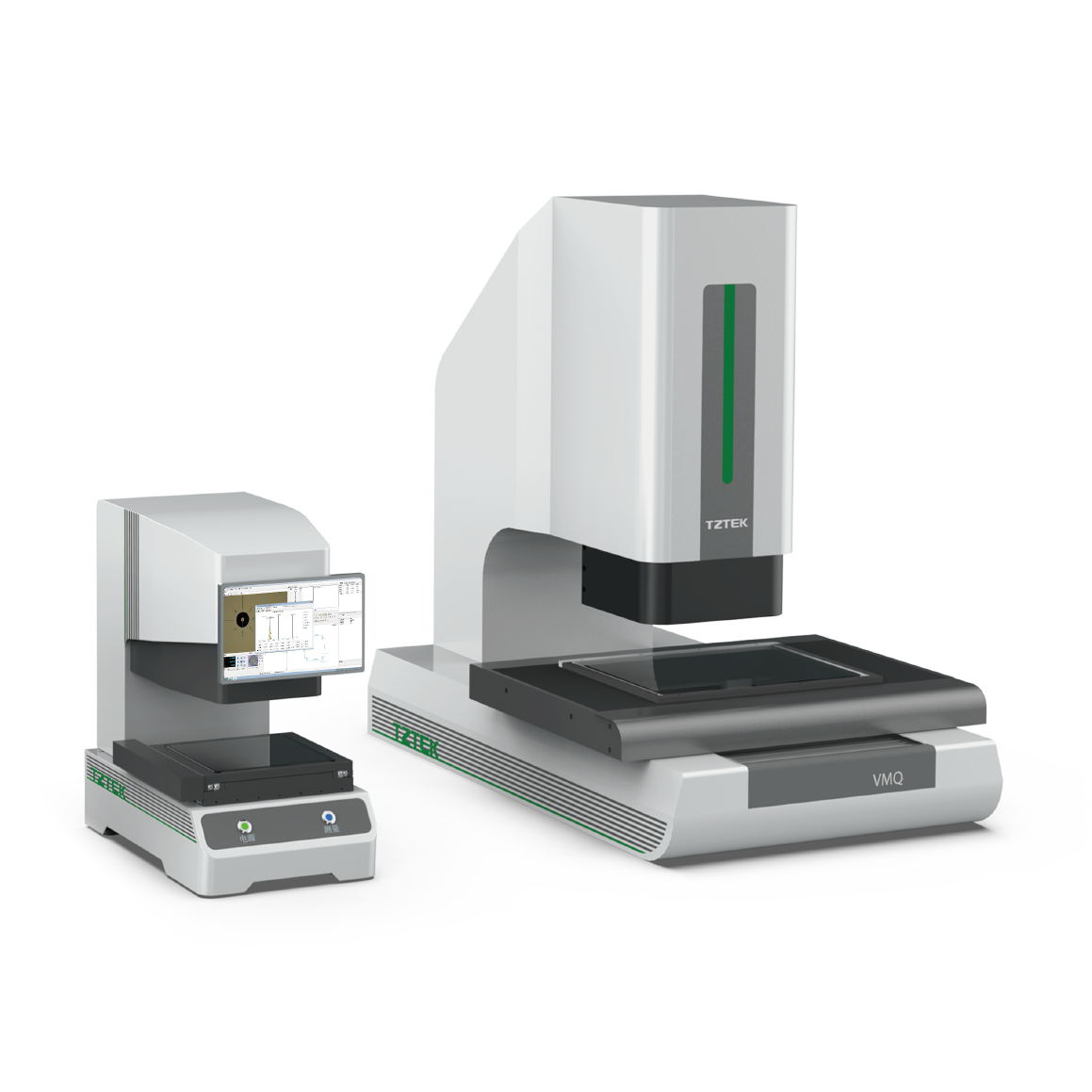

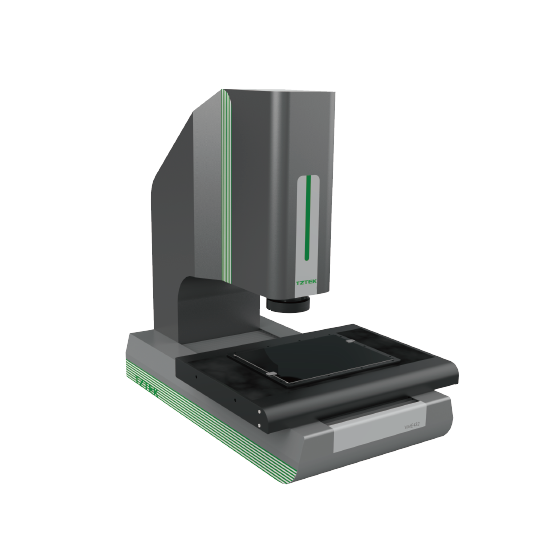

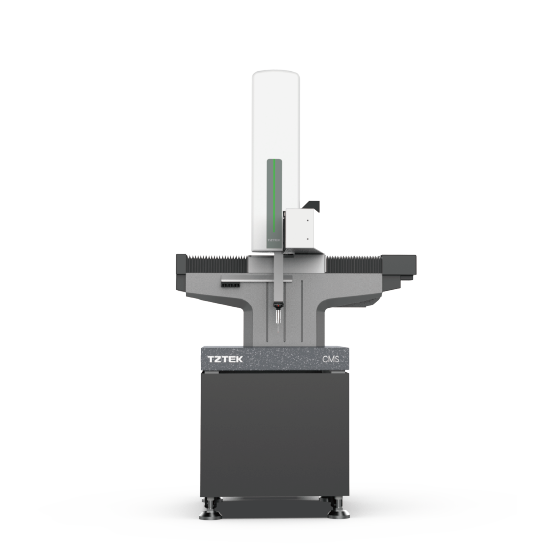

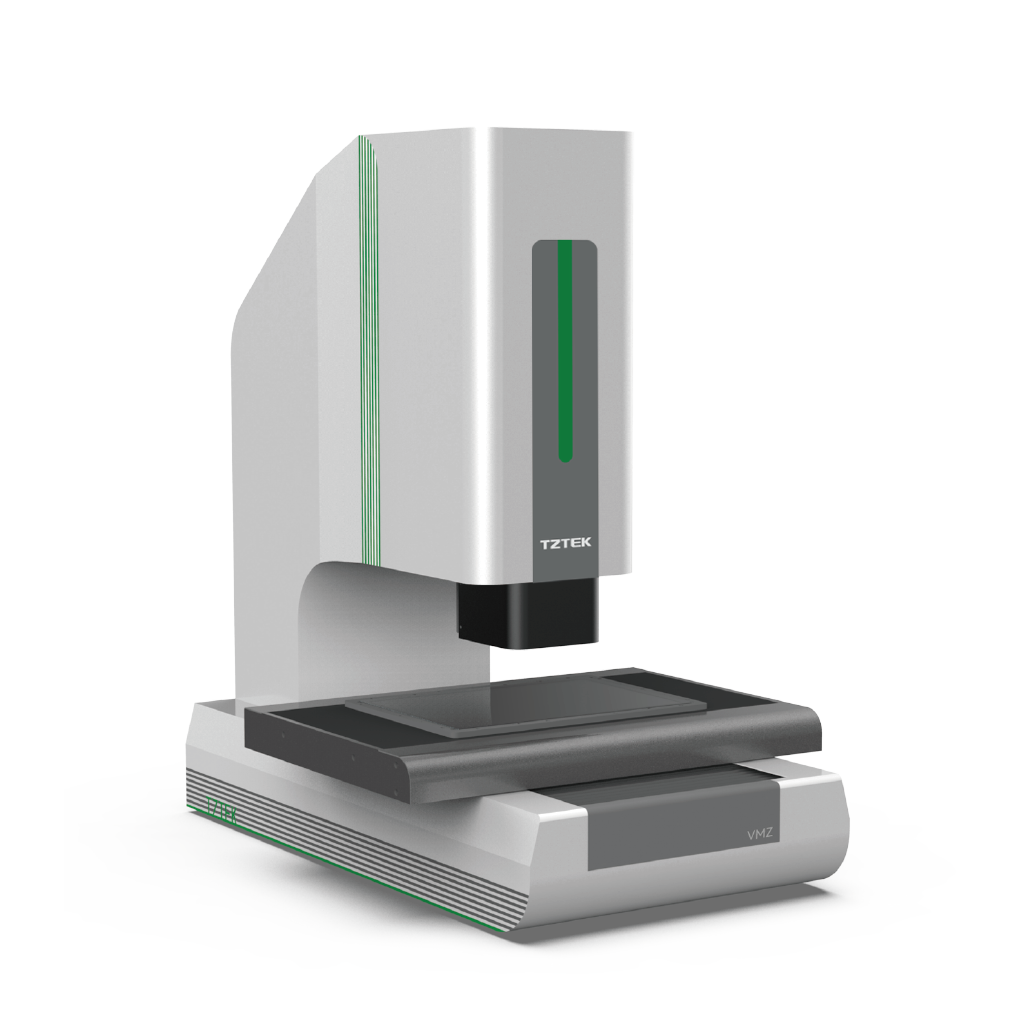

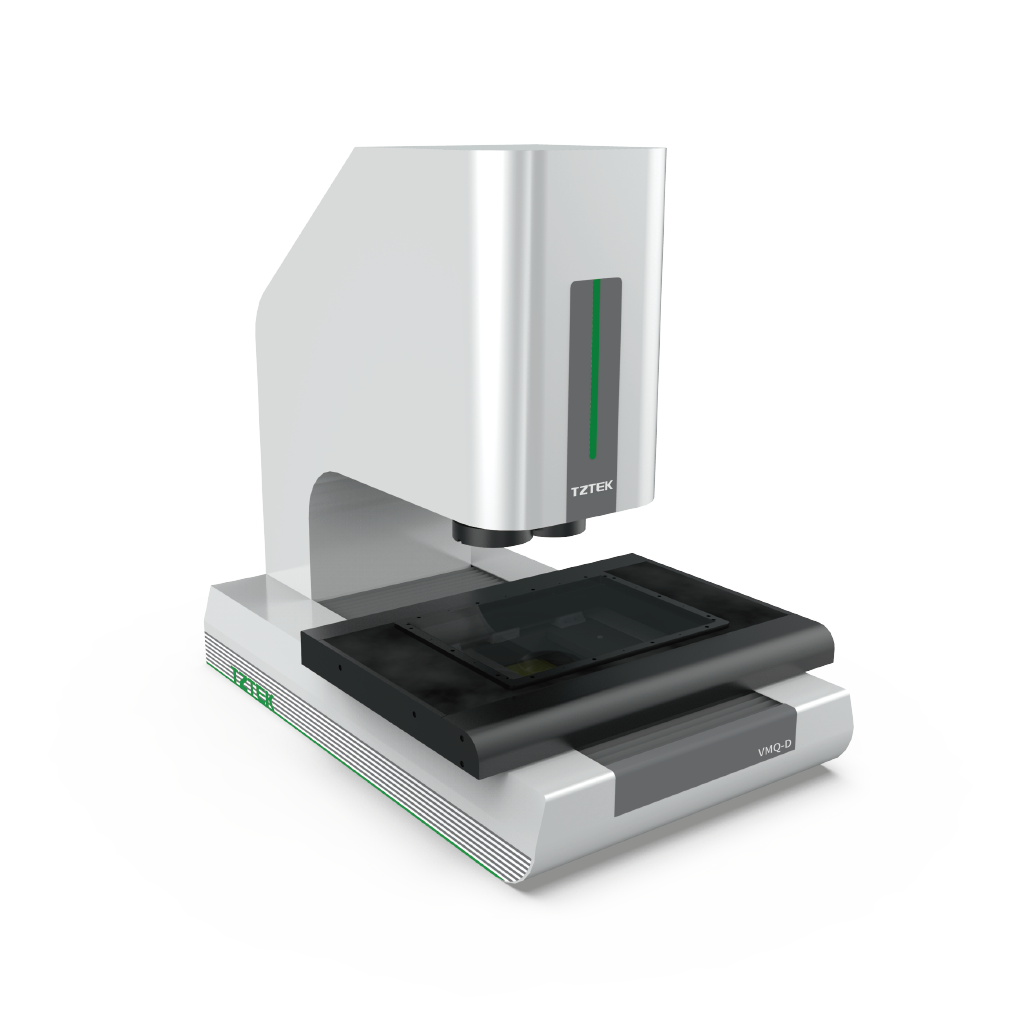

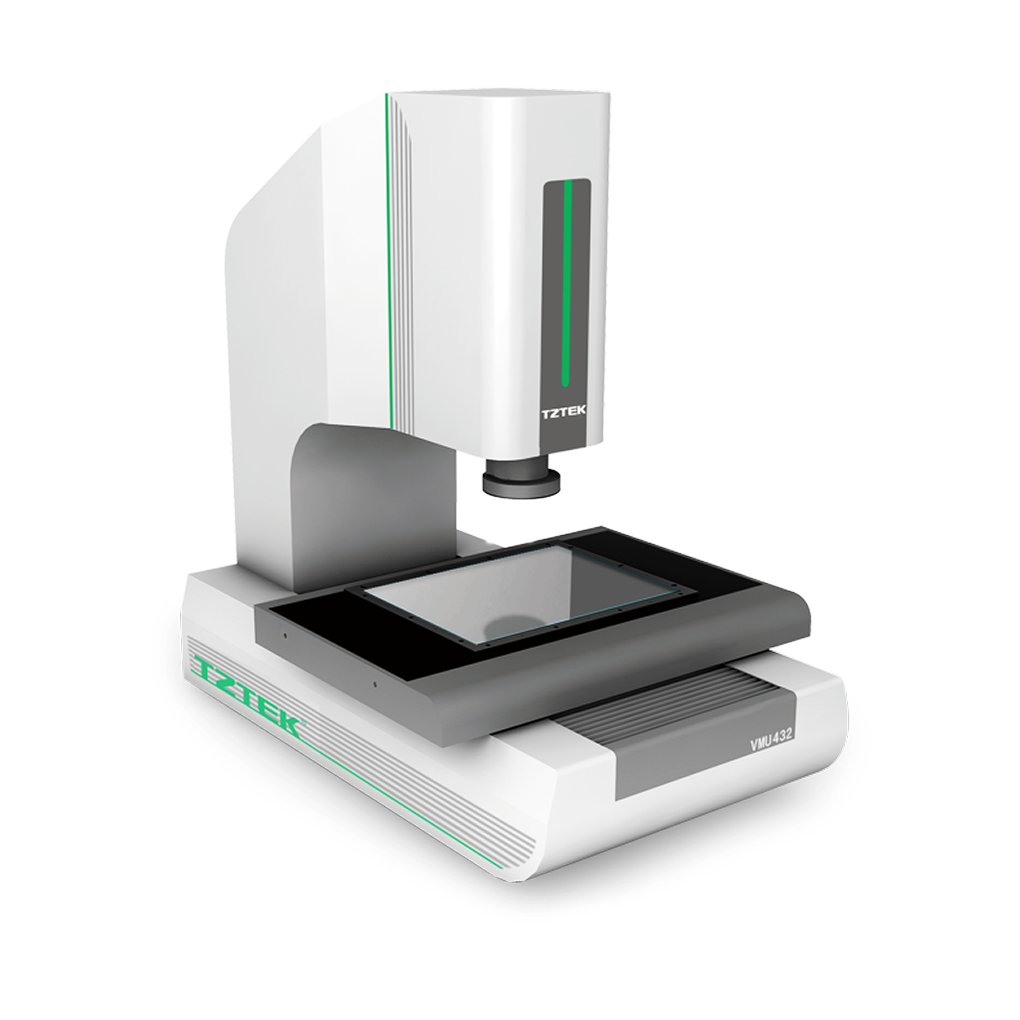

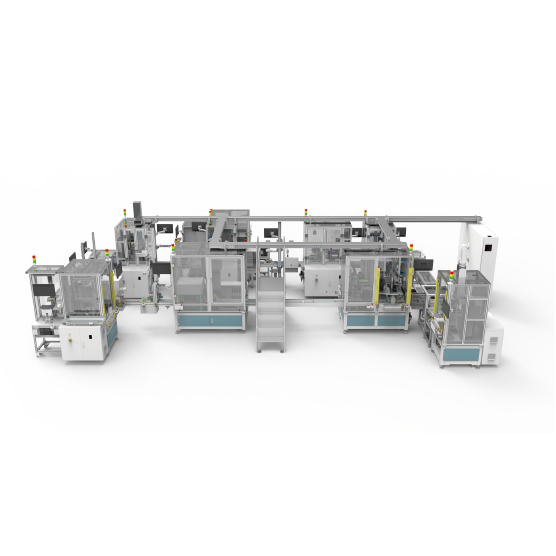

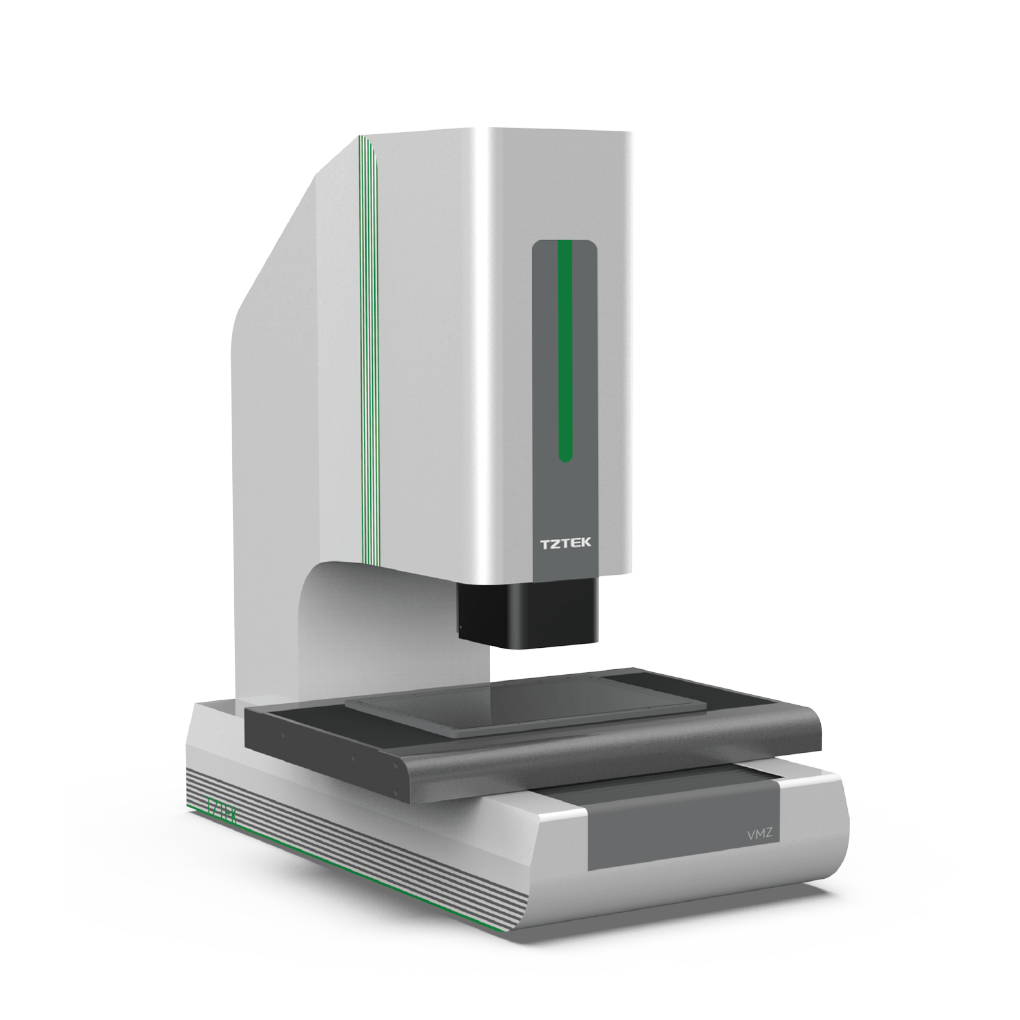

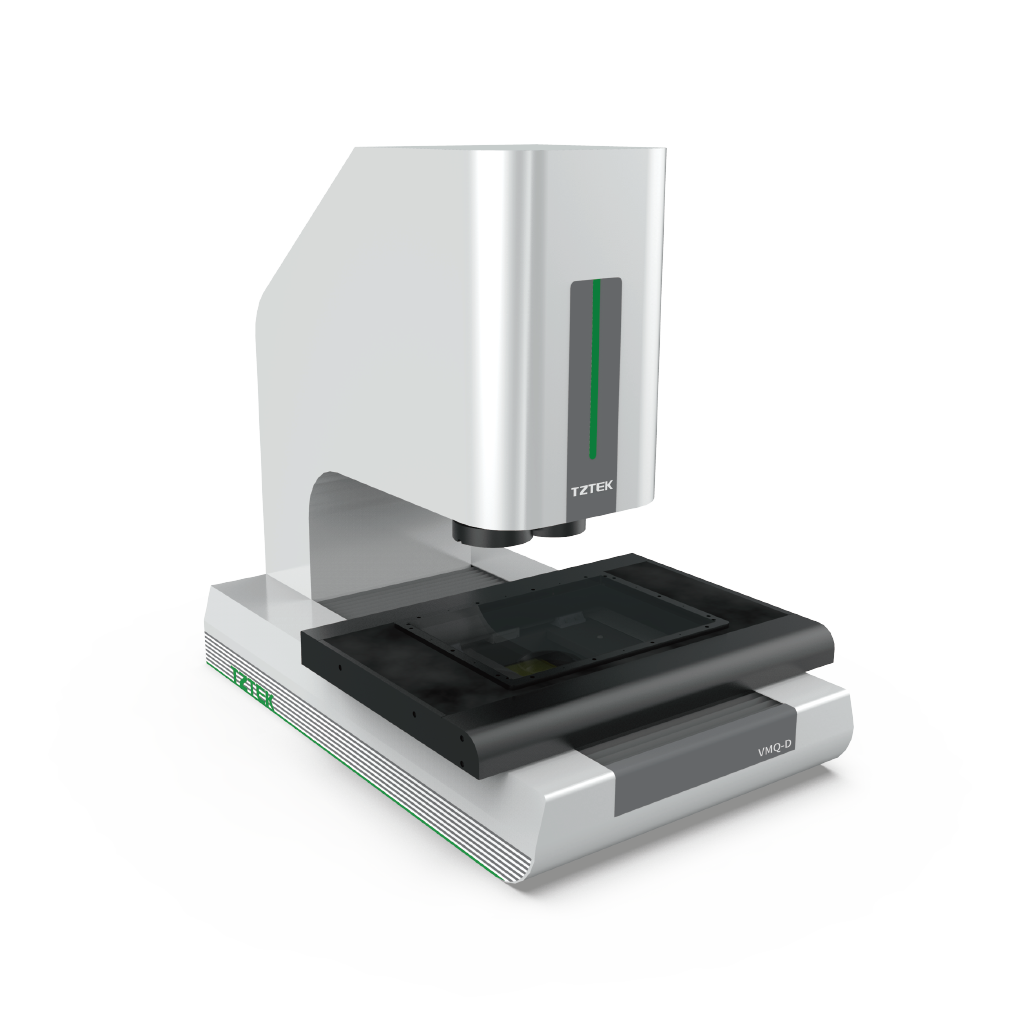

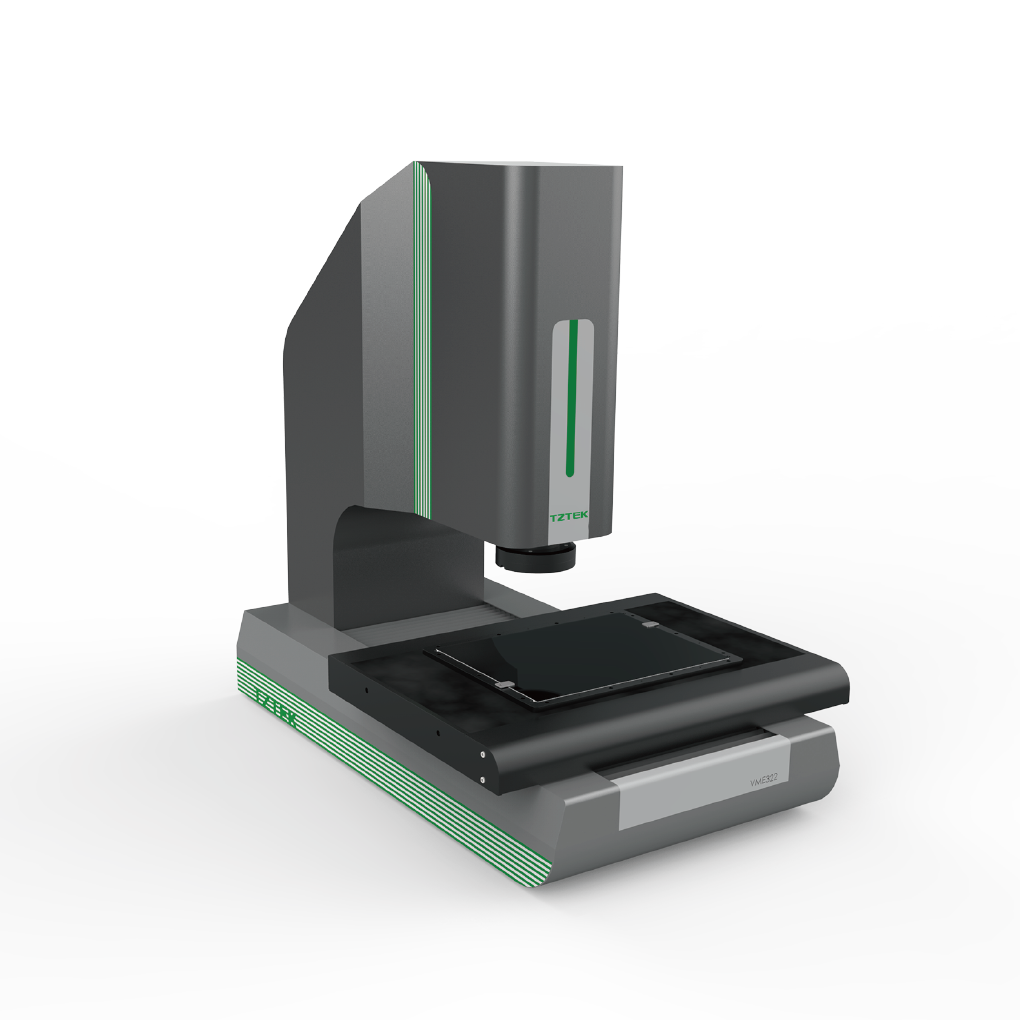

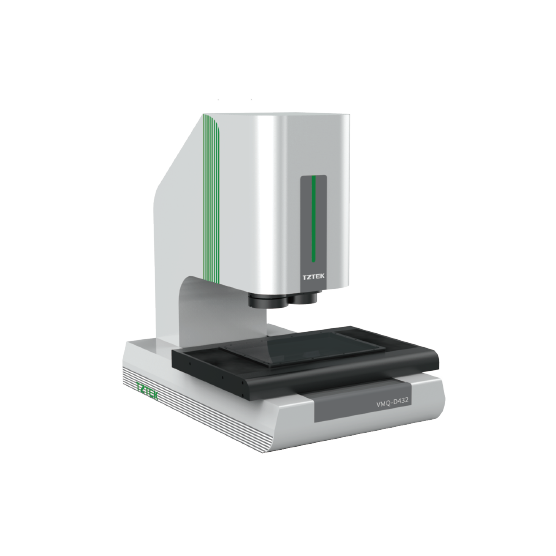

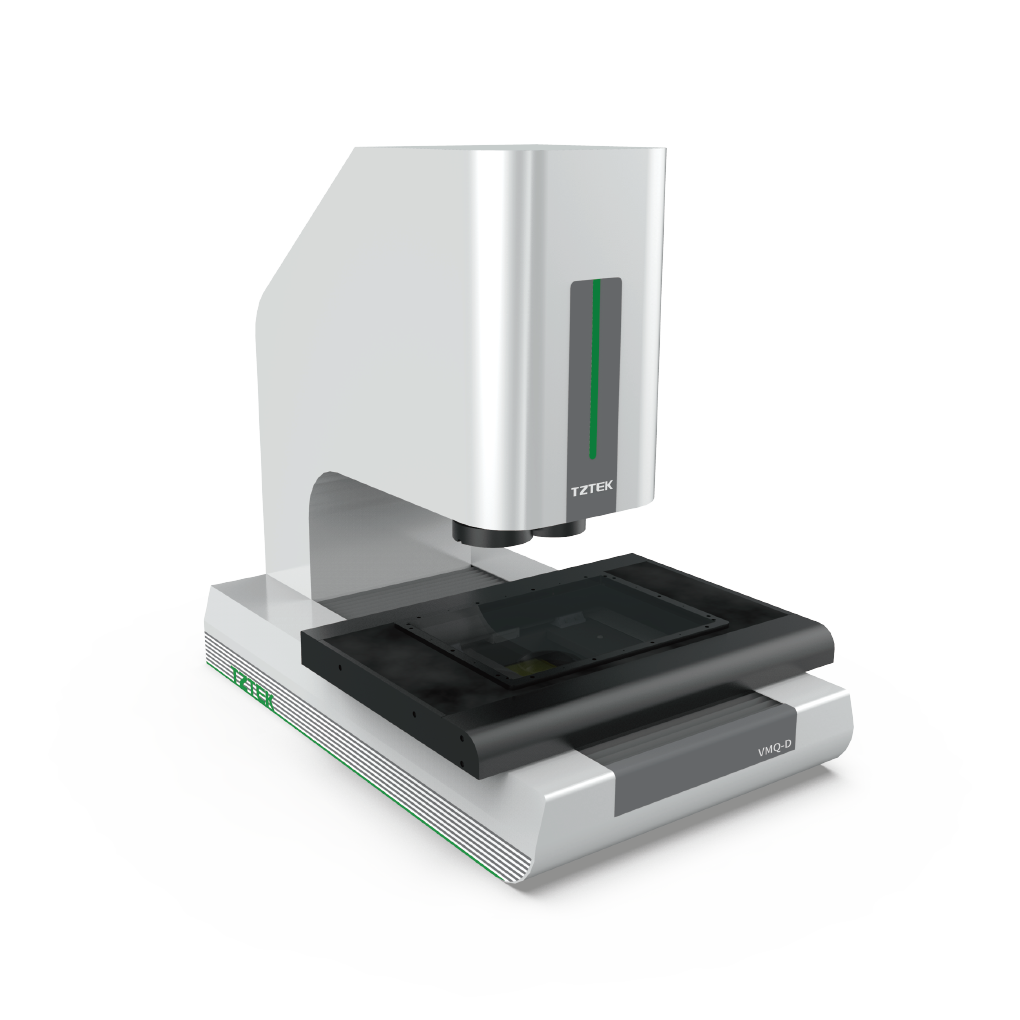

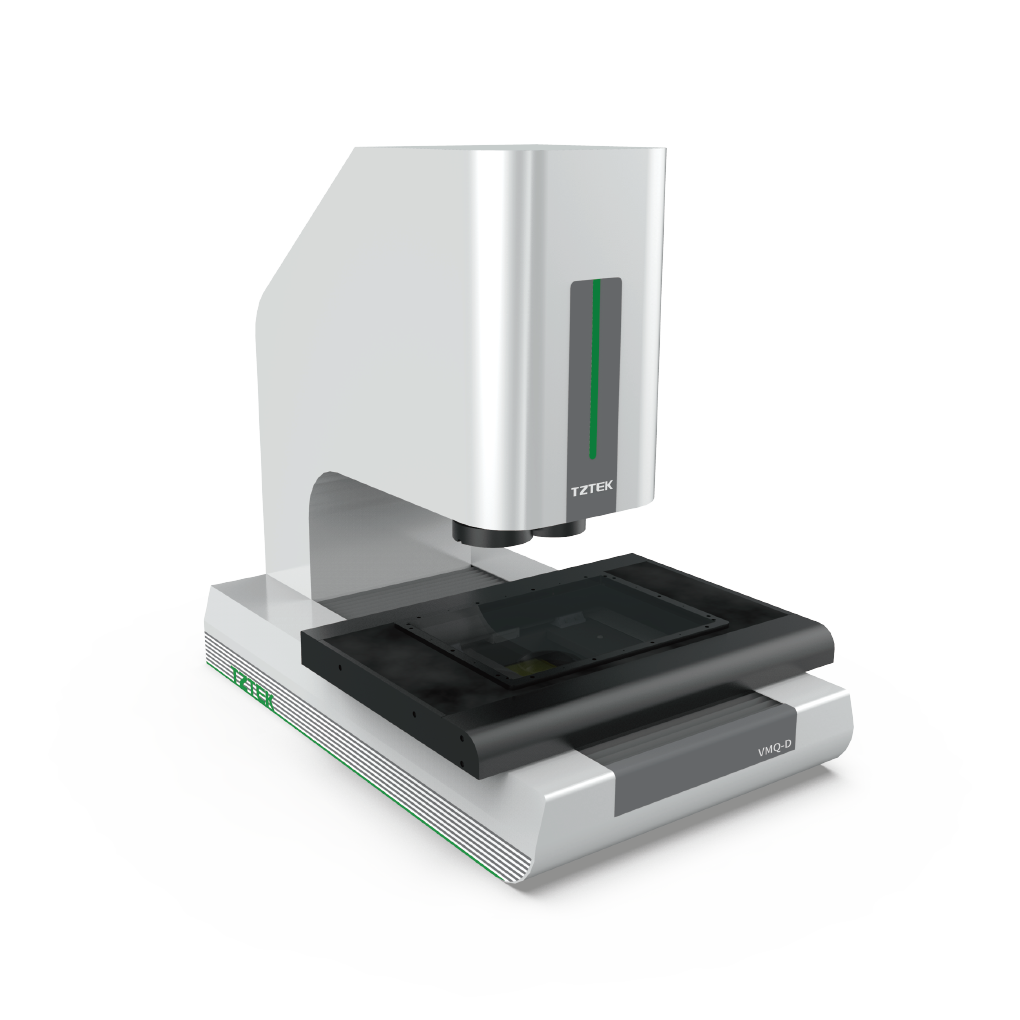

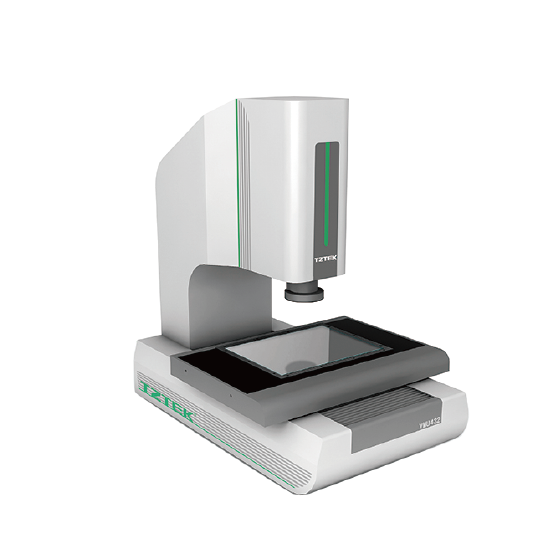

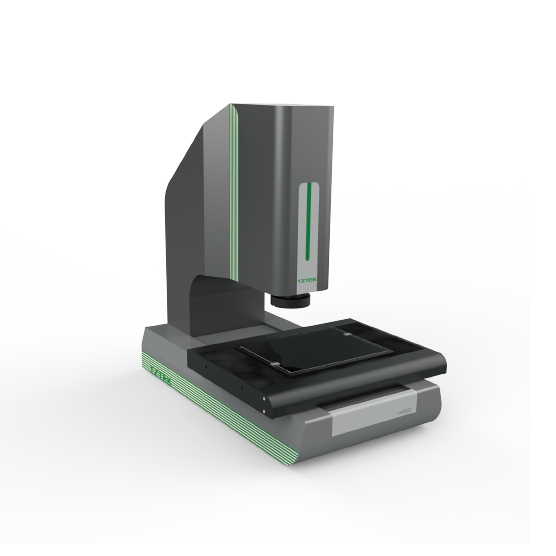

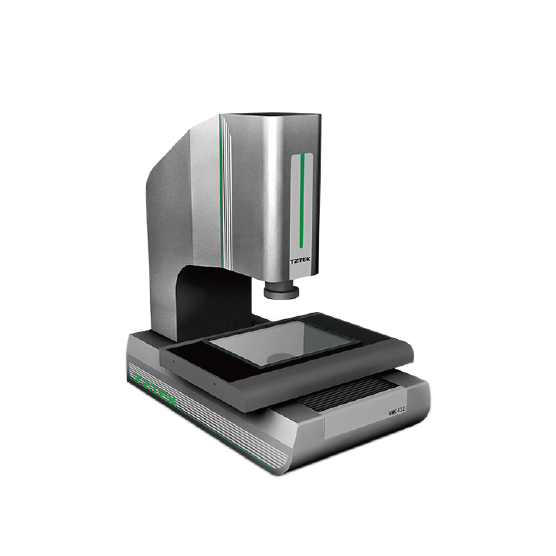

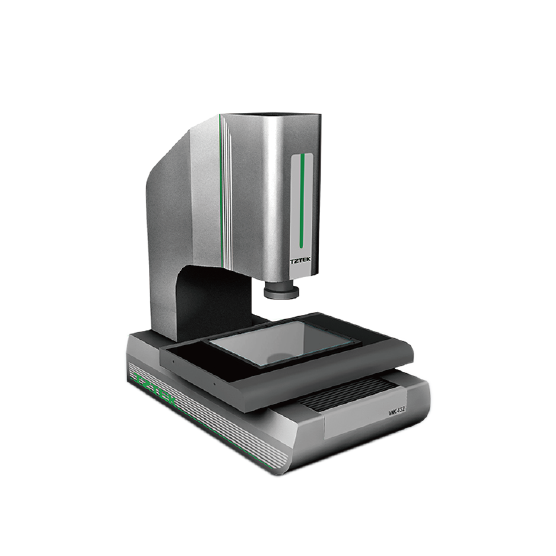

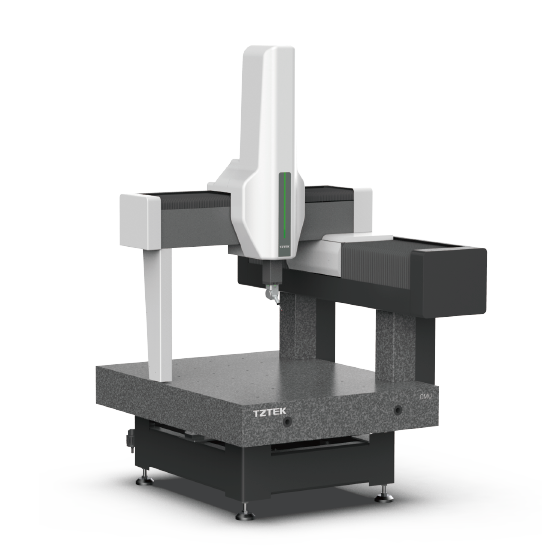

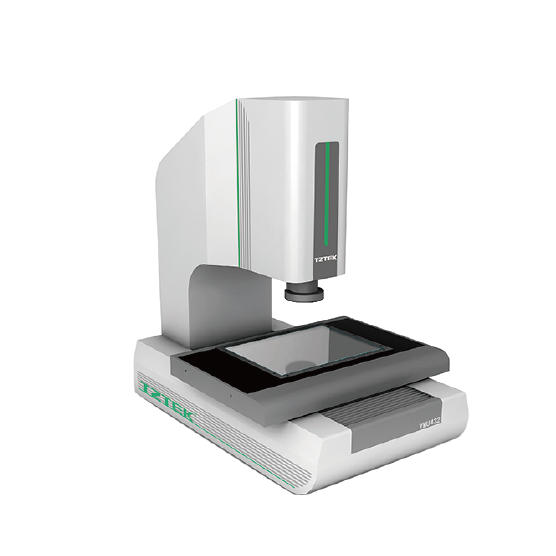

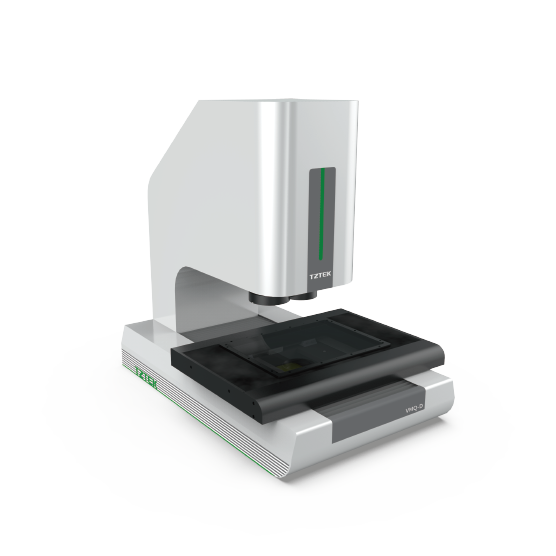

VMQ-D Quick Video Measuring Machine

PRODUCT FEATURES

-

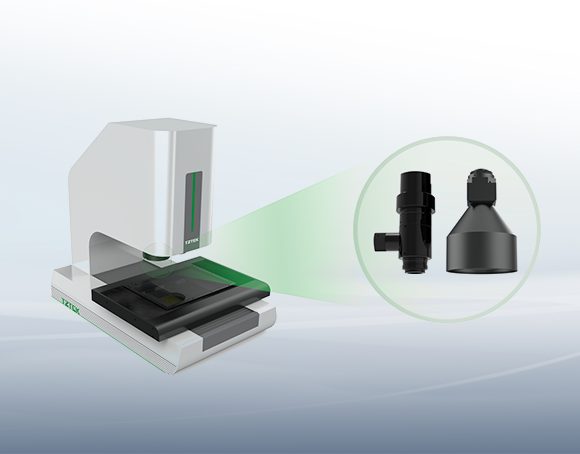

Dual lens design, balancing measurement accuracy and efficiency

Dual lens design, balancing measurement accuracy and efficiencyEquipped with large filed of view lens and an automatic zoom lens

Meets complex measurement requirements of various sizes and tolerances for different industries

Measurement data from both lenses can be seamlessly integrated

-

High precision and high efficiency with one-button quick measuring

High precision and high efficiency with one-button quick measuringAccurate and quick measuring, capable of identifying multiple work pieces in one FOV, suitable for batch measuring

Automatic image registration, quick positioning of work pieces without assistance of fixture

Automatically load program without the need of manual search -Fusion measurement ensures quick measurement for large workpiece

PRODUCT SPECIFICATIONS

-

VMQ-D

-

-

Travel (mm)

400x300x200

-

External Dimensions (mm)

900 x 1240 x 1739

-

Weight (kg)

475

-

RELATED INDUSTRIES

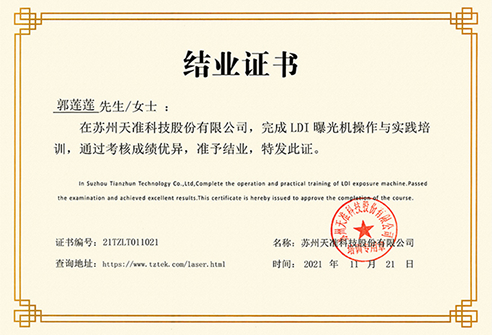

MEASUREMENT PLAN FOR MEDICAL & HEALTHCARE

The medical and healthcare industry is crucial for safeguarding people's health and life safety, playing a vital role in social development, with its development direction focused on high-end, precision, and intelligence. This industry is characterized by rapid technological advancements and diverse market demands, with related products typically having numerous specifications and small production batches.

Industry Case Studies

-

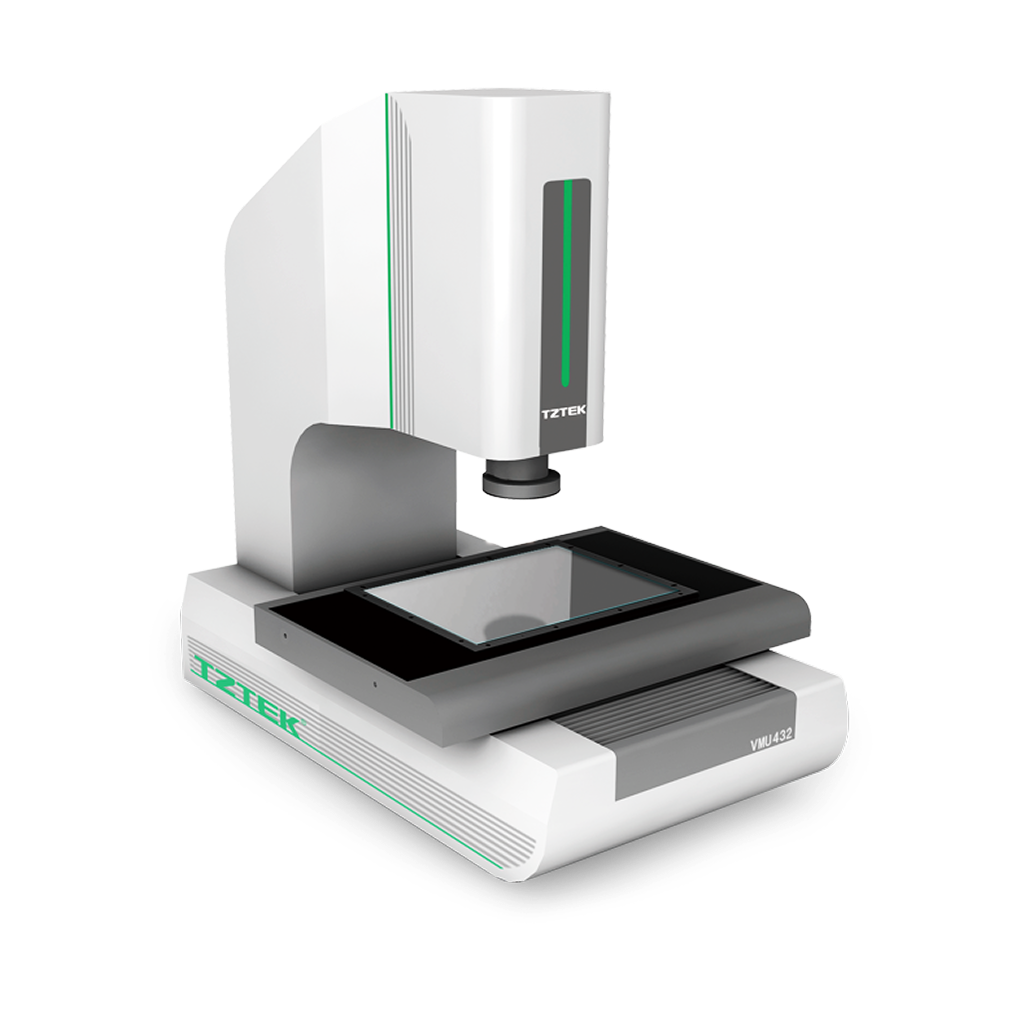

Vascular Stent Measurement (VMU)

-

Measurement Challenges

Vascular stents are typically made from metal or polymer mesh structures and are placed in narrow or occluded blood vessels to maintain blood flow. They are widely used in the treatment of vascular diseases, including coronary arteries, intracranial arteries, carotid arteries, renal arteries, and femoral arteries. The key dimensions of a vascular stent include diameter, wall thickness, wire diameter, and length. -

Solutions

Quick video measuring machine enables rapid and precise measurement of key dimensions of vascular stents, offering easy operation and good applicability. It can also replace microscopes for defect detection.

-

-

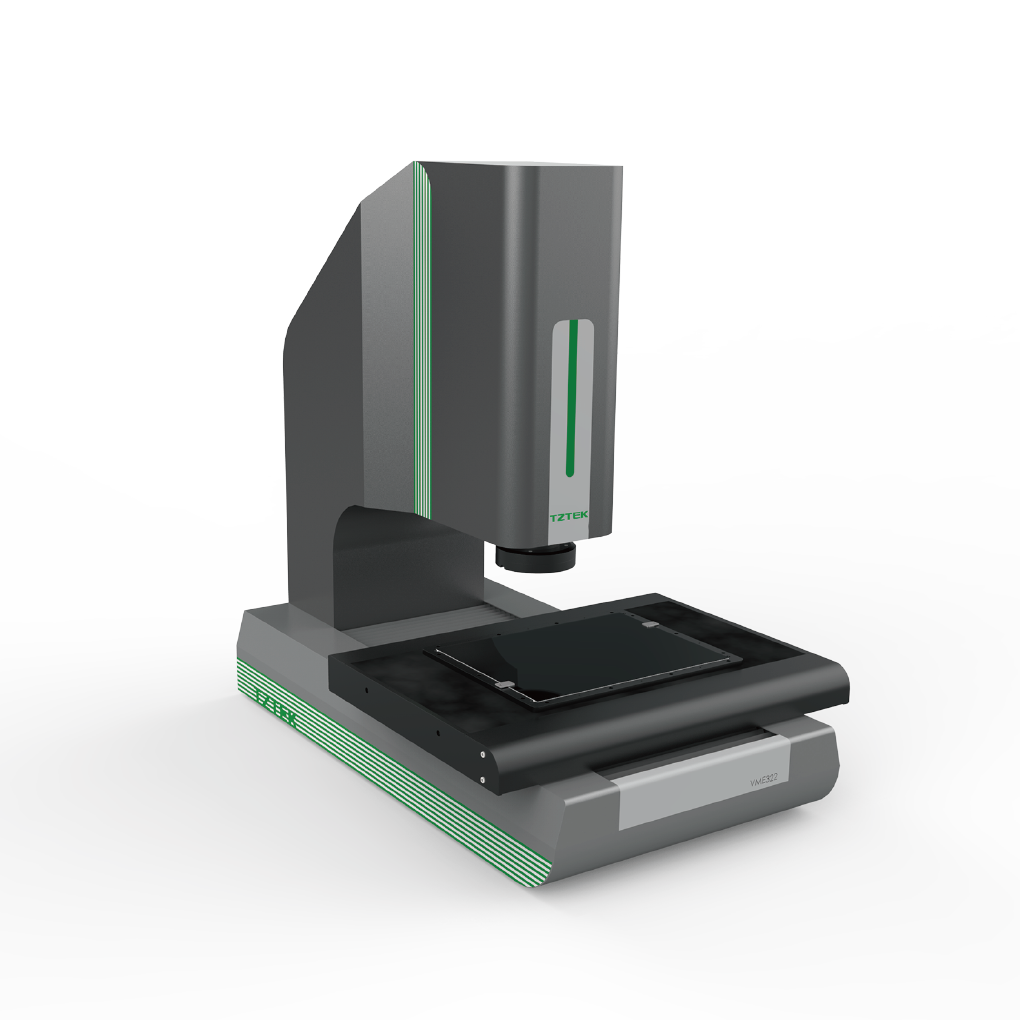

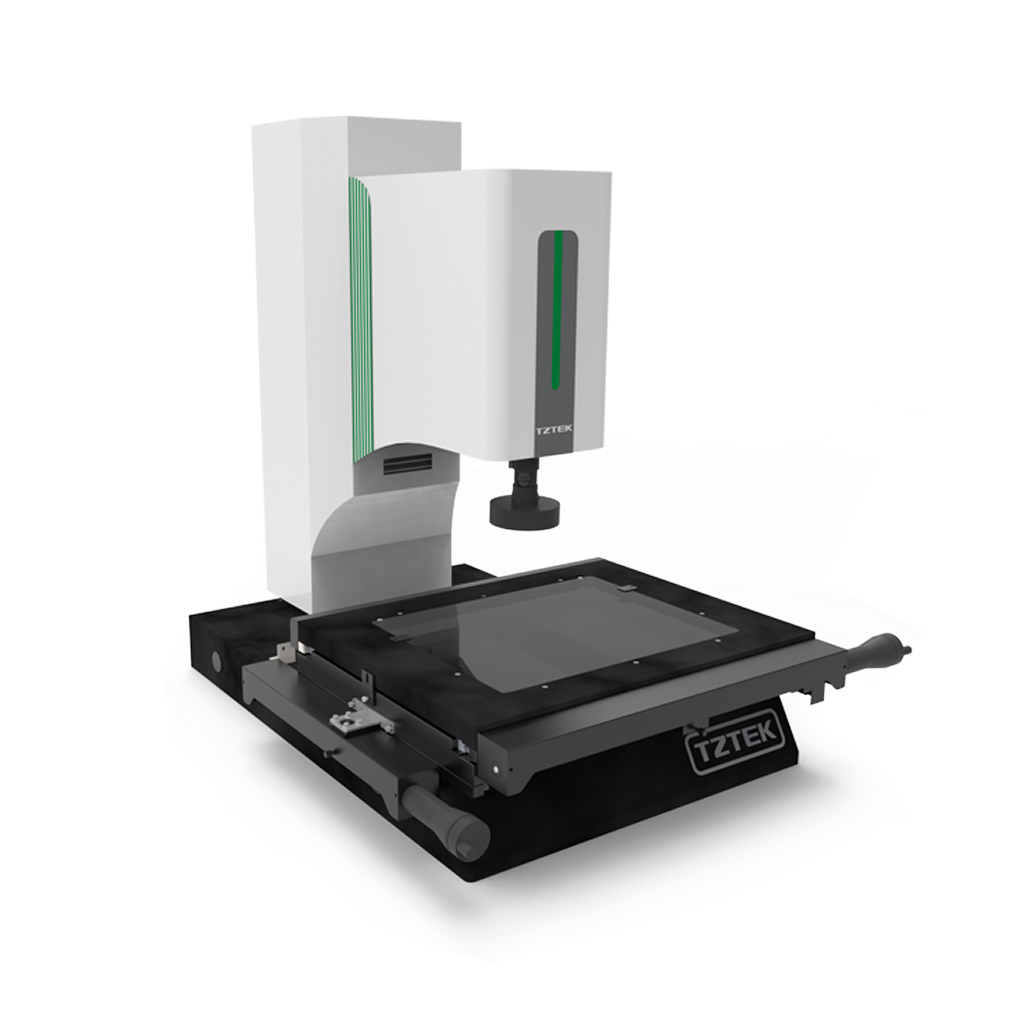

Surgical Instrument Measurement (VME)

-

Measurement Challenges

An anastomosis device, used as a replacement for manual suturing, utilizes titanium staples to join tissue, similar to a stapler. It is widely used in thoracic, gastrointestinal, hepatobiliary, and urological surgeries. The anastomosis device consists of parts such as the anvil, stapling chamber, shaft, handle, battery compartment, and knob. To ensure the device's performance, it is crucial to control the dimensional accuracy of key components. -

Solutions

Video measuring machine can be used to rapidly measure the dimensions of key features such as the distance between the anvil's surface protrusions and the length or spacing of holes in the stapling chamber, with convenient operation and good applicability.

-

-

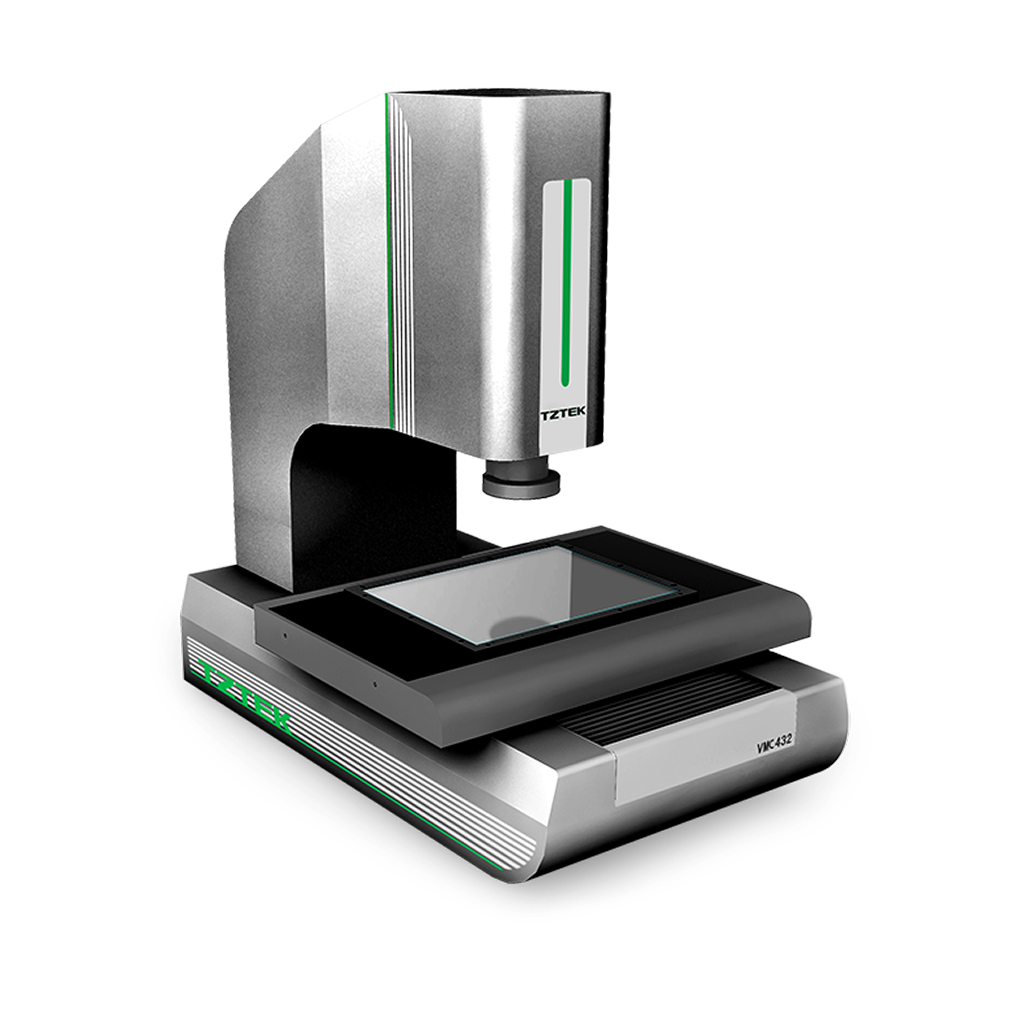

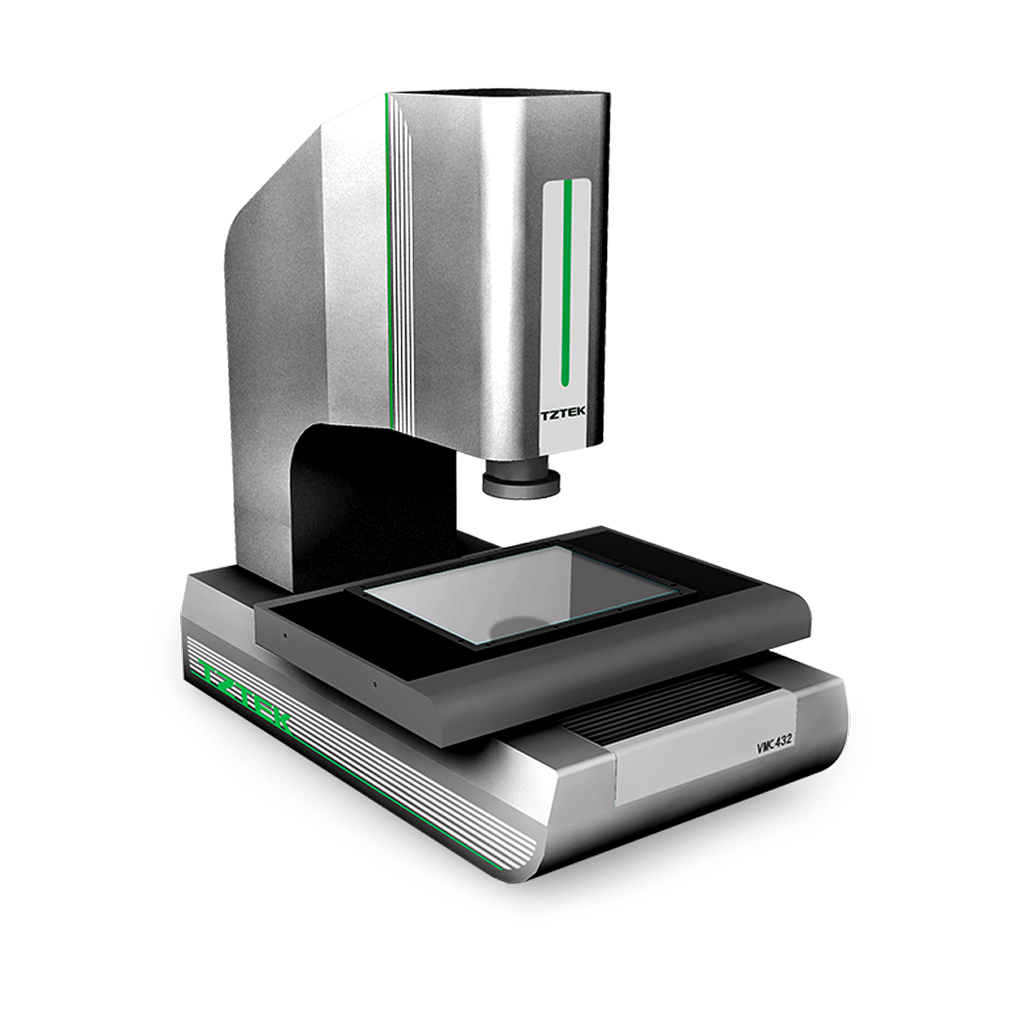

Microfluidic Chip Measurement (VMC)

-

Measurement Challenges

A microfluidic chip controls fluid at the micrometer scale and integrates basic laboratory functions (sample preparation, reaction, separation, detection, etc.) on a few square centimeters of chip surface. It offers advantages such as low sample or reagent consumption, high efficiency with multiple testing channels, low contamination due to isolated channels, portability, and low reliance on specialized medical staff. It has broad application prospects in biomedical research, drug development, environmental monitoring, and health quarantine. The specifications of microfluidic chips are varied, and the channel dimensions are the key control items. -

Solutions

Video measuring machin equipped with a spectral confocal sensor, uses the optical system to identify and locate the microfluidic chip product, and measure channel widths and the dimensions of sample or reaction wells. Under the guidance of the spectral confocal sensor, it measures the channel depth and flatness of the sample or reaction wells. The system provides high precision, fast speed, and broad product applicability.

-

-

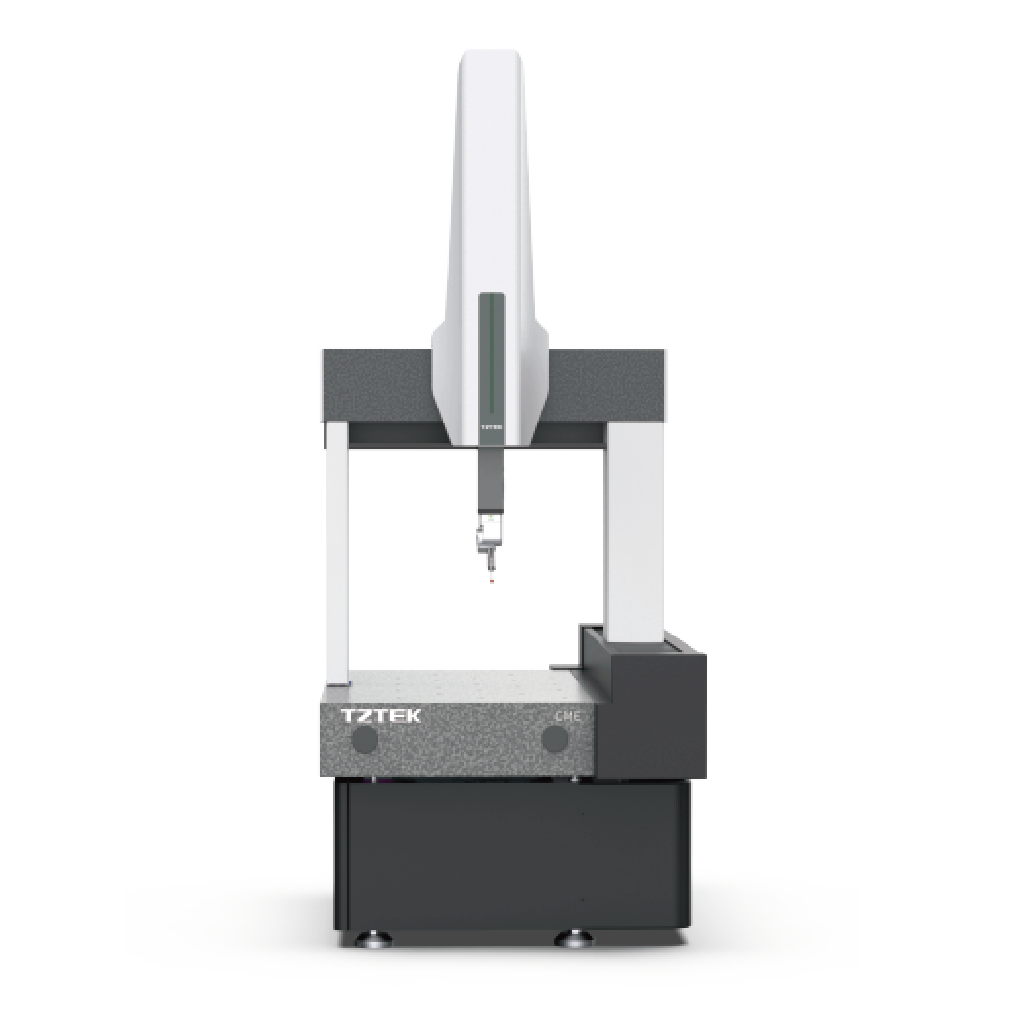

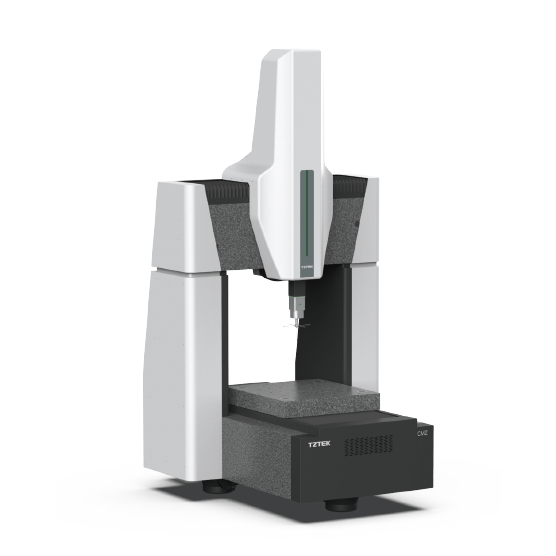

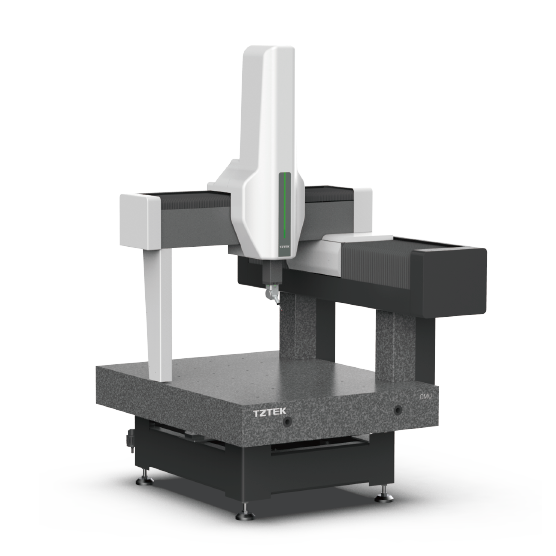

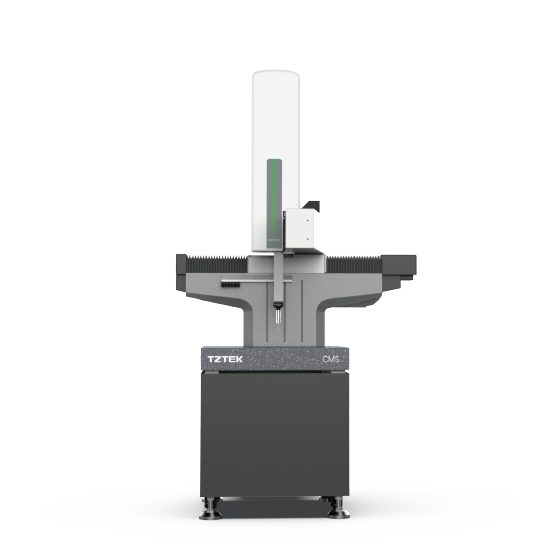

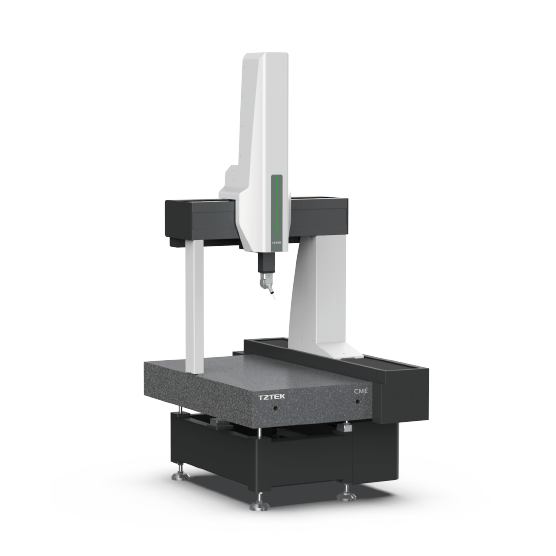

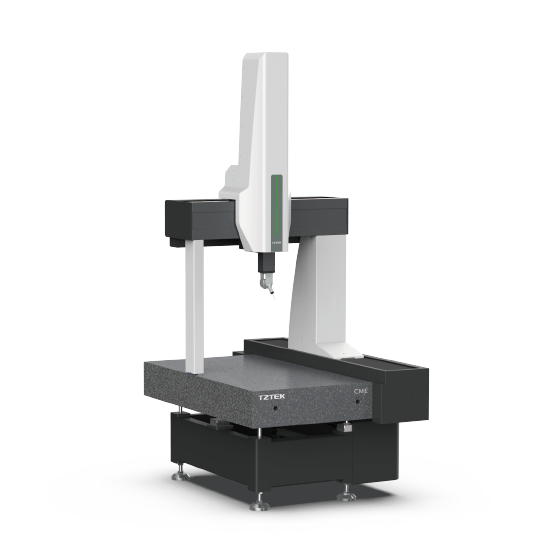

Artificial Joint Measurement (CME)

-

Measurement Challenges

Artificial joints are used to replace damaged human joints and restore joint movement functionality. For example, a total hip joint replacement includes four components: the acetabular cup, liner, femoral head, and femoral stem. The acetabular cup and femoral head form the joint surface, while the liner covers the inside of the acetabular cup and contacts the femoral head to reduce friction and wear. The dimensional accuracy of the mating parts is critical, as it affects the patient's experience and joint longevity. -

Solutions

The coordinate measuring machine (CMM) performs full-size measurement of artificial joint components, such as the groove or profile of the acetabular cup, acetabular depth and inner diameter, the outer shape of the liner (length, width, angle), the diameter or roundness of the femoral head, and the contour of the femoral stem.

-

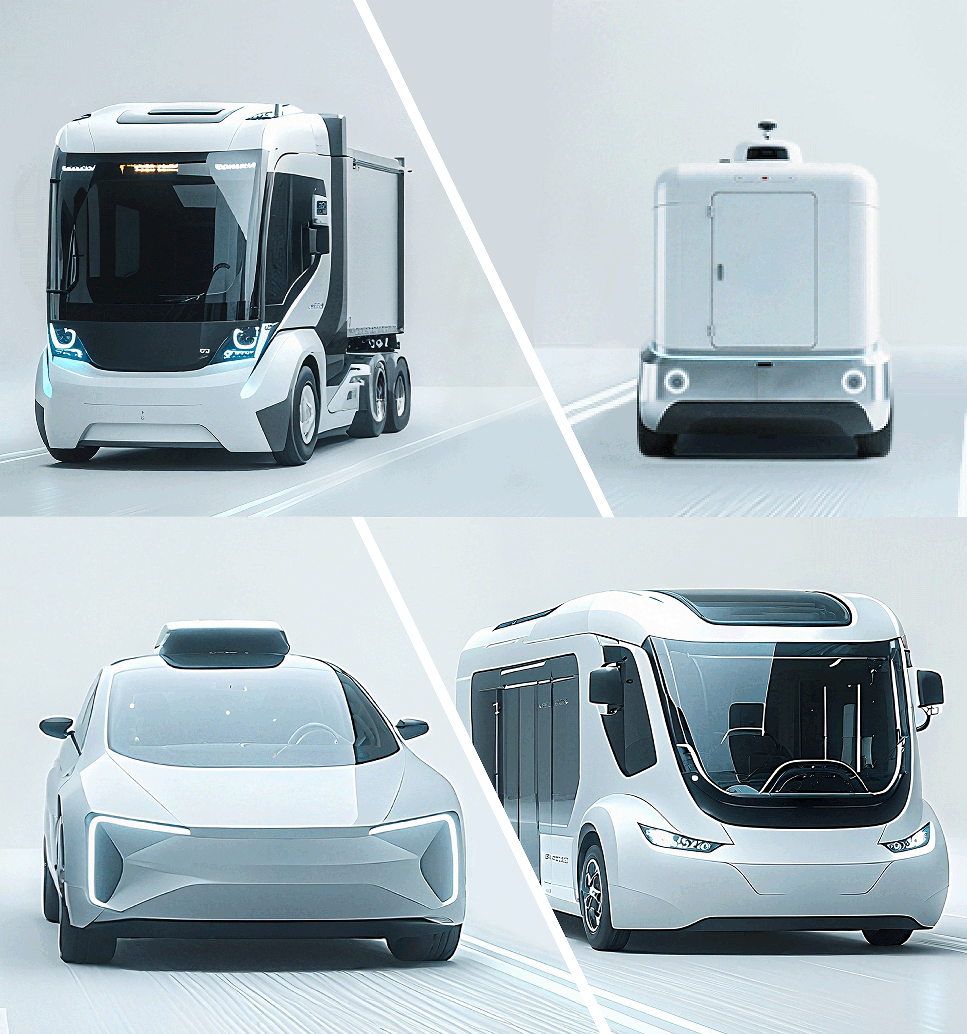

MEASUREMENT PLAN FOR AUTOMOTIVE

The automotive industry is undergoing a shift towards electrification and intelligence, with product iteration cycles significantly shortened. Batteries, motors, and electronic control systems have become the three core components of new vehicles.

Industry Case Studies

-

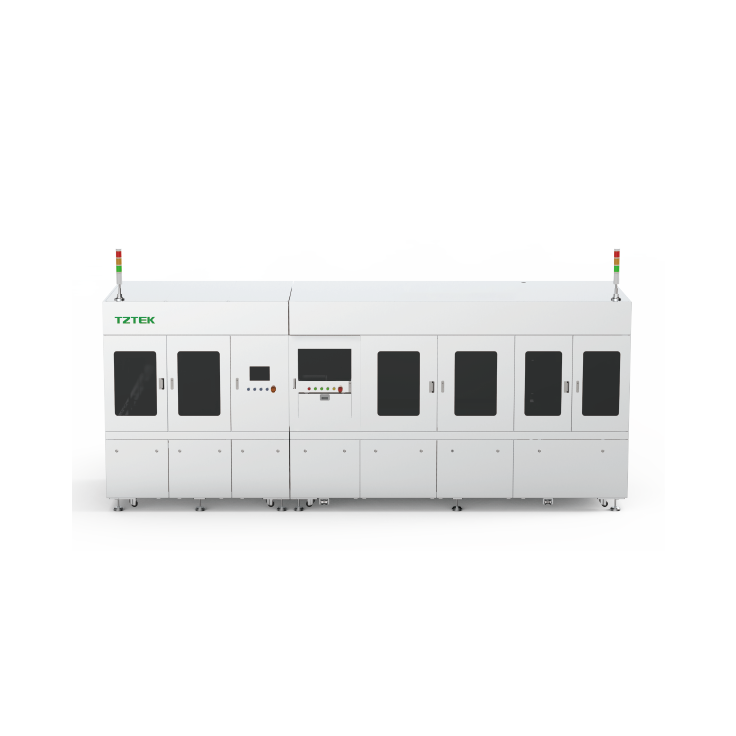

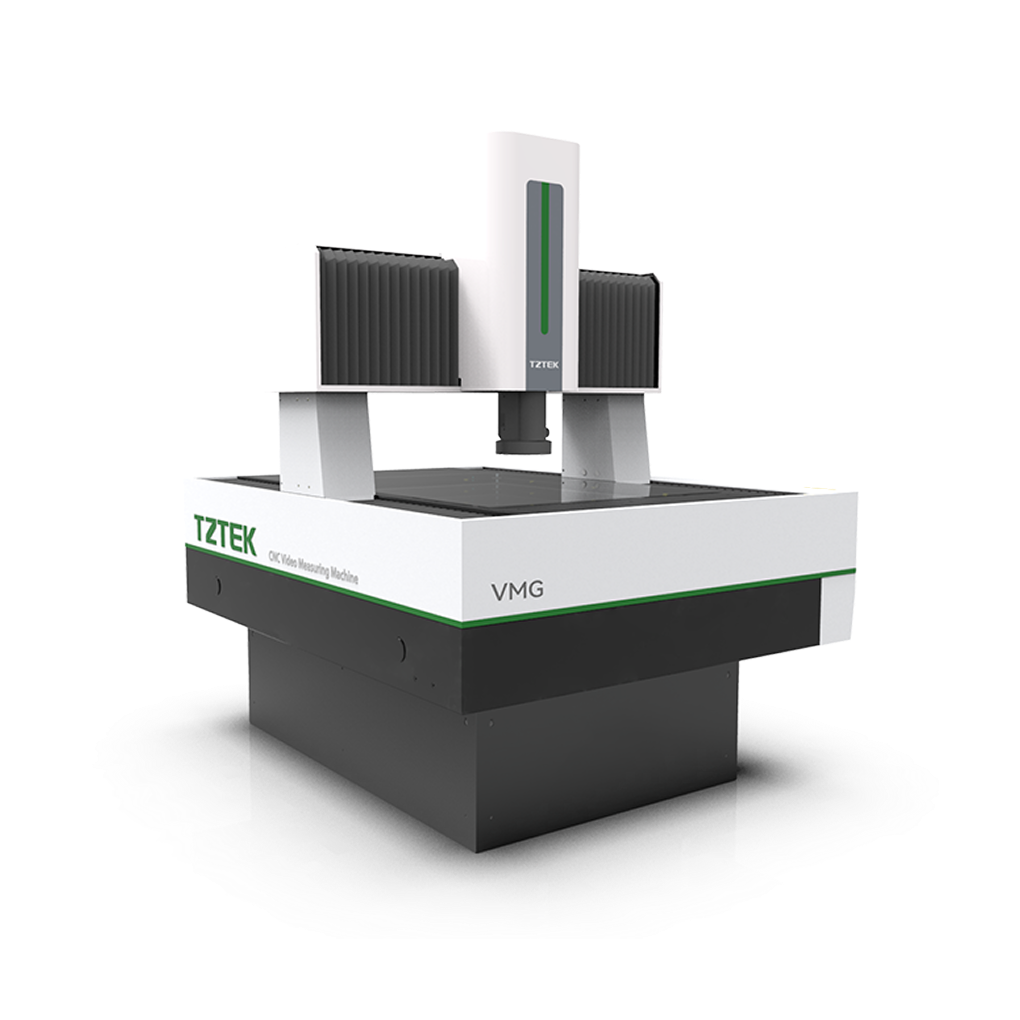

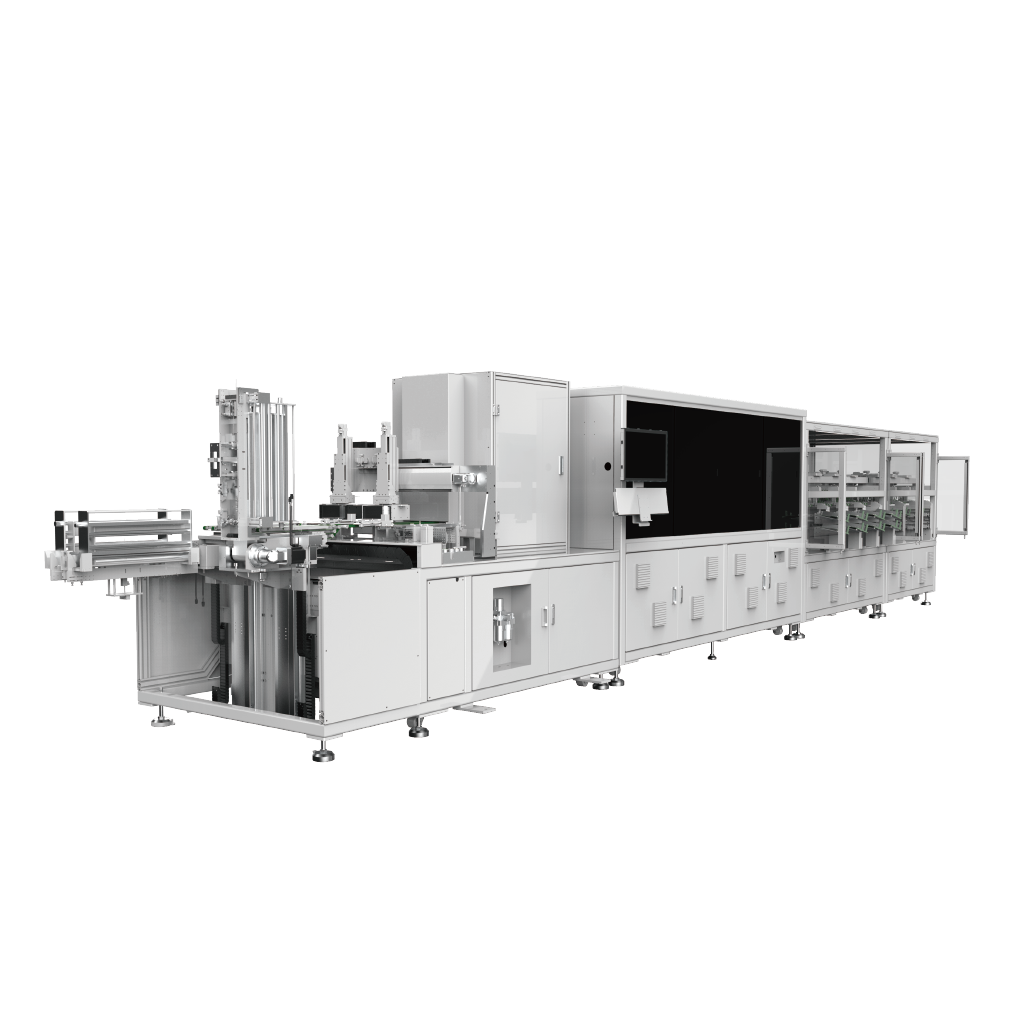

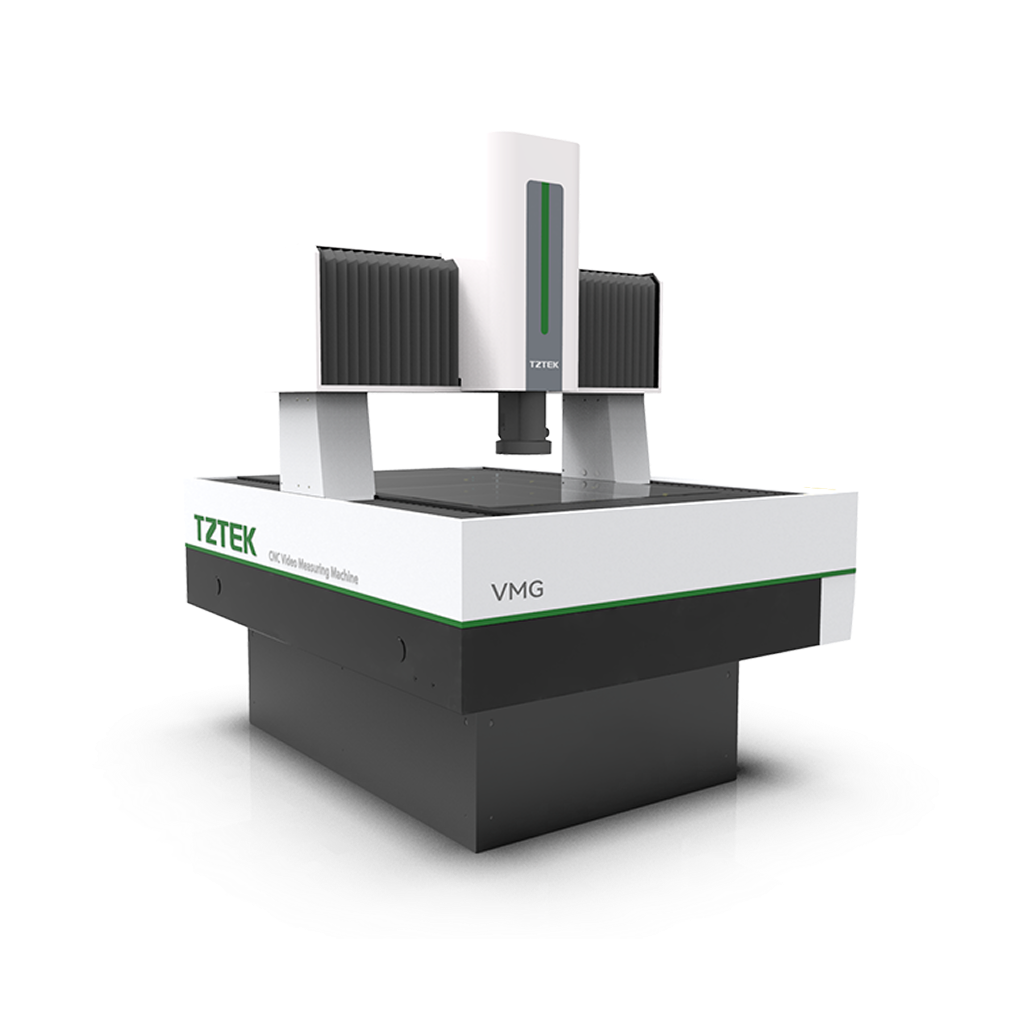

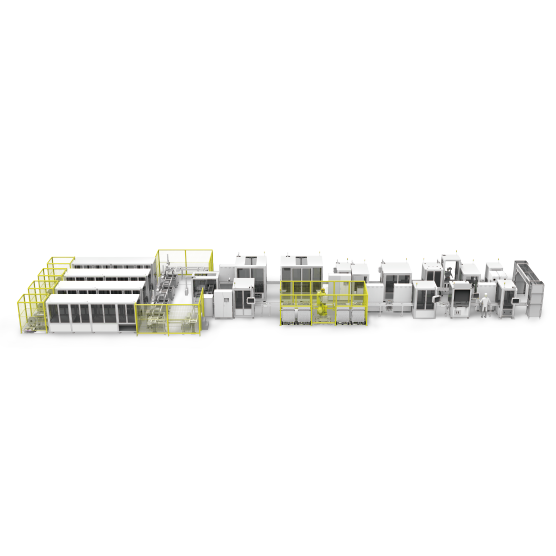

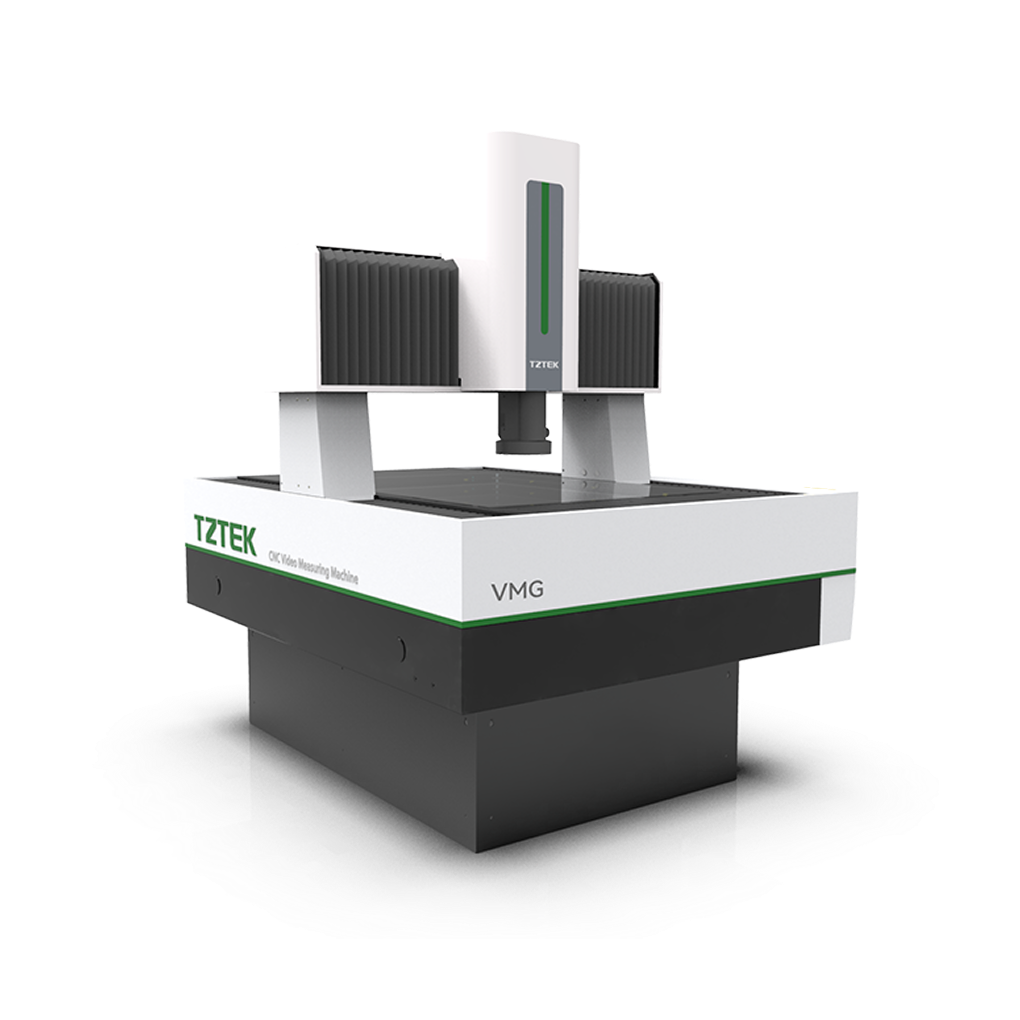

Measurement of Power Battery Electrode Sheets (VMG)

-

Measurement Challenges

Stacked cell batteries feature high energy density, long lifetime, high reliability, and fast charging. The internal structure consists of a series of positive electrode sheets, separators, and negative electrode sheets stacked together. These electrode sheets are slit from membrane materials into appropriate specifications, with the key focus on controlling the dimensions of the electrode sheets and the size of burrs generated during slitting. Larger metal burrs can pierce the separator, causing short circuits between the positive and negative electrodes. -

Solutions

The battery electrode sheets can be placed on the workbench without precise alignment. The software can automatically identify the position and orientation of the electrode sheets, enabling fast dimensional measurement. Burrs are clearly visible on the display, replacing a microscope for its measurement.

-

-

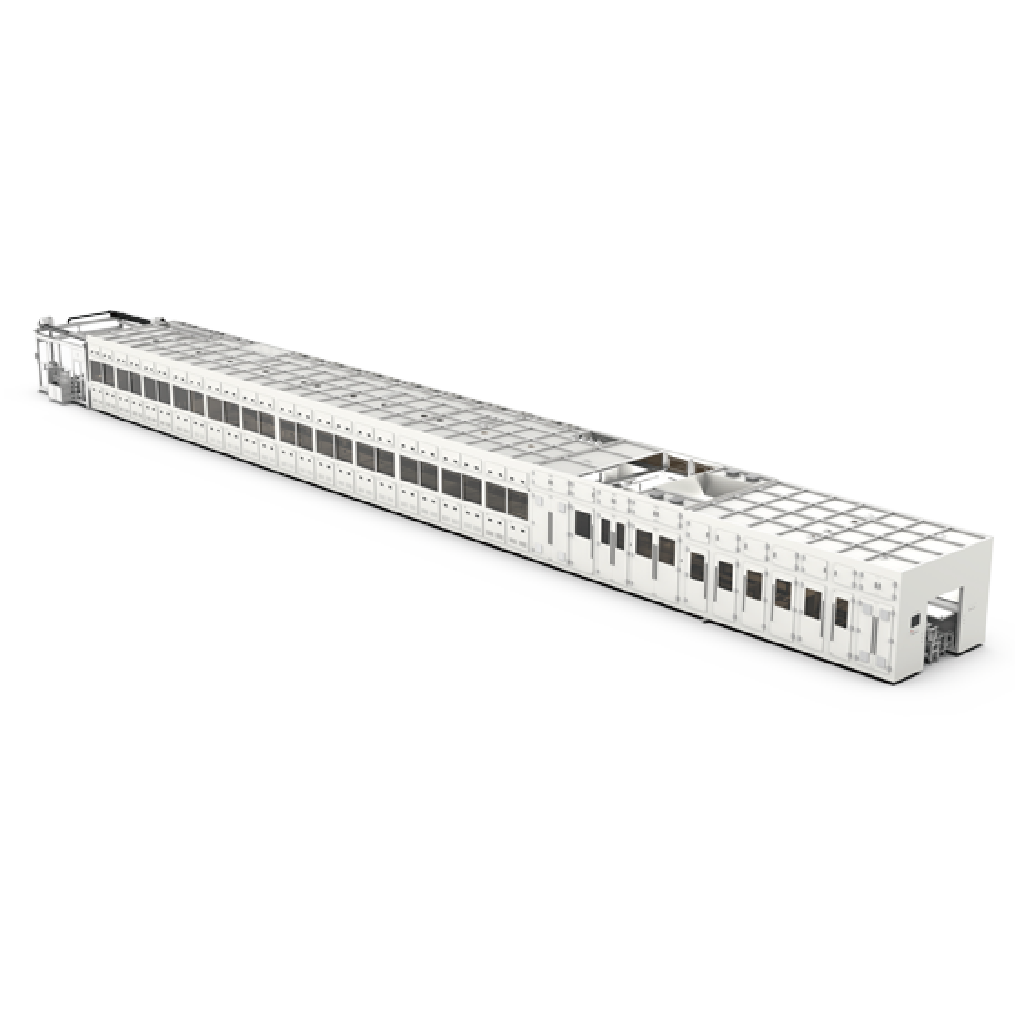

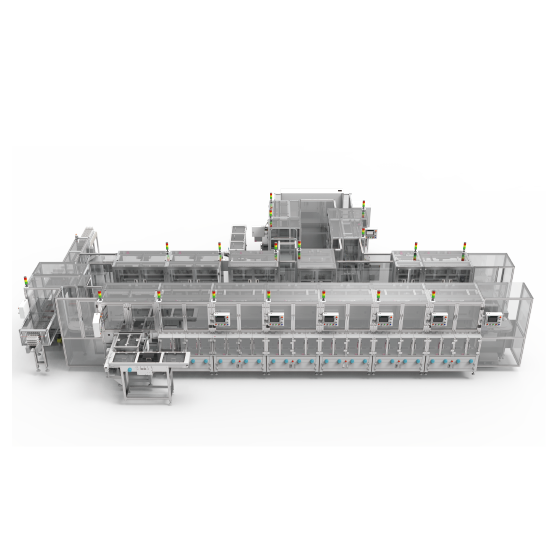

Measurement of Motor Silicon Steel Sheets (VMC)

-

Measurement Challenges

Silicon steel sheets are essential components of motor rotors or stators, typically formed through stamping and stacking processes. The dimensional accuracy of silicon steel sheets must be strictly controlled. -

Solutions

Silicon steel sheets can be placed on the workbench without requiring precise alignment. The software can automatically identifies the position and orientation of the sheets, enabling rapid dimensional measurement.

-

-

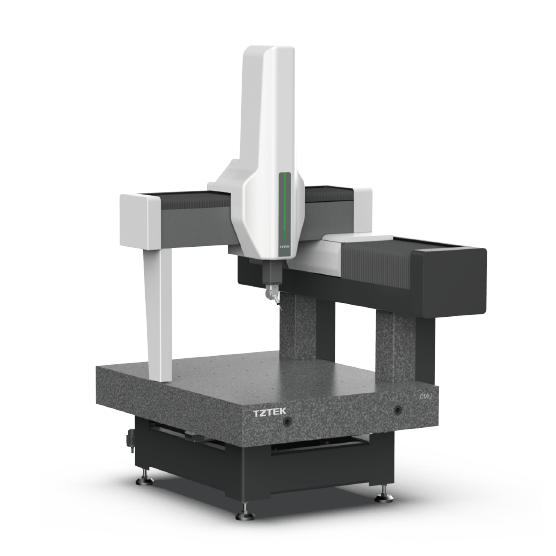

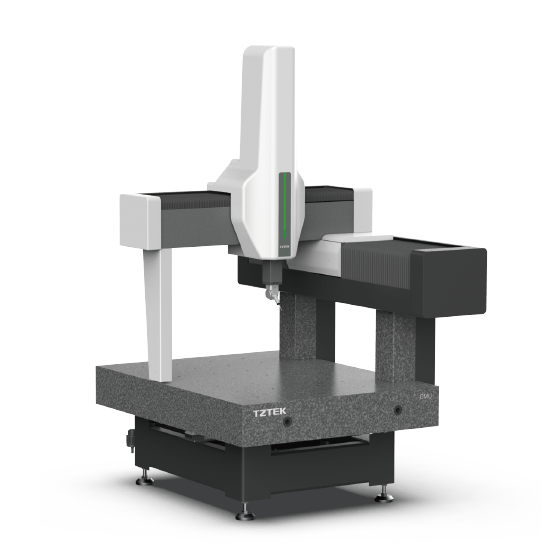

Measurement of Scroll Discs in Scroll Compressors (CMU)

-

Measurement Challenges

Scroll compressors, commonly used in automotive air conditioning systems, are known for their high efficiency, energy savings, low noise, high reliability, simple structure, compact size, light weight, and smooth operation. The core of the compressor consists of a fixed involute scroll disc and an eccentric, orbiting involute scroll disc, which together form the compression chamber. The machining accuracy of the scroll discs is crucial to the compressor's performance. -

Solutions

The Coordinate Measuring Machine (CMM), equipped with a scanning probe, quickly completes full-size measurements of both static and dynamic scroll discs, including profile contours, wall thickness, perpendicularity, and other key dimensions.

-

MEASUREMENT PLAN FOR 3C

"3C" refers to Computers, Communication, and Consumer Electronics. Computers include laptops, desktops, tablets, printers, servers, hard disk drives, monitors, keyboards, mice, etc. Communication includes mobile phones, telephones, fax machines, modems, wireless routers, wireless networking devices, etc. Consumer Electronics include televisions, refrigerators, air conditioners, washing machines, vacuum cleaners, digital cameras, game consoles, home theaters, hair dryers, microwave ovens, rice cookers, electric ovens, air purifiers, energy-saving lamps, LED lights, Bluetooth headphones, Bluetooth speakers, etc. The 3C industry is characterized by large production volumes and rapid innovation cycles.

Industry Case Studies

-

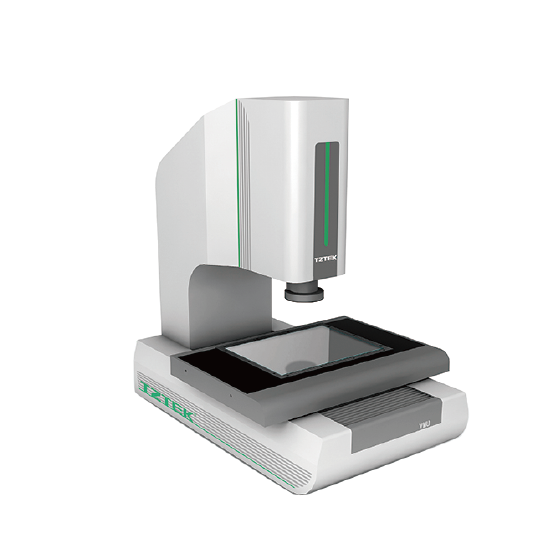

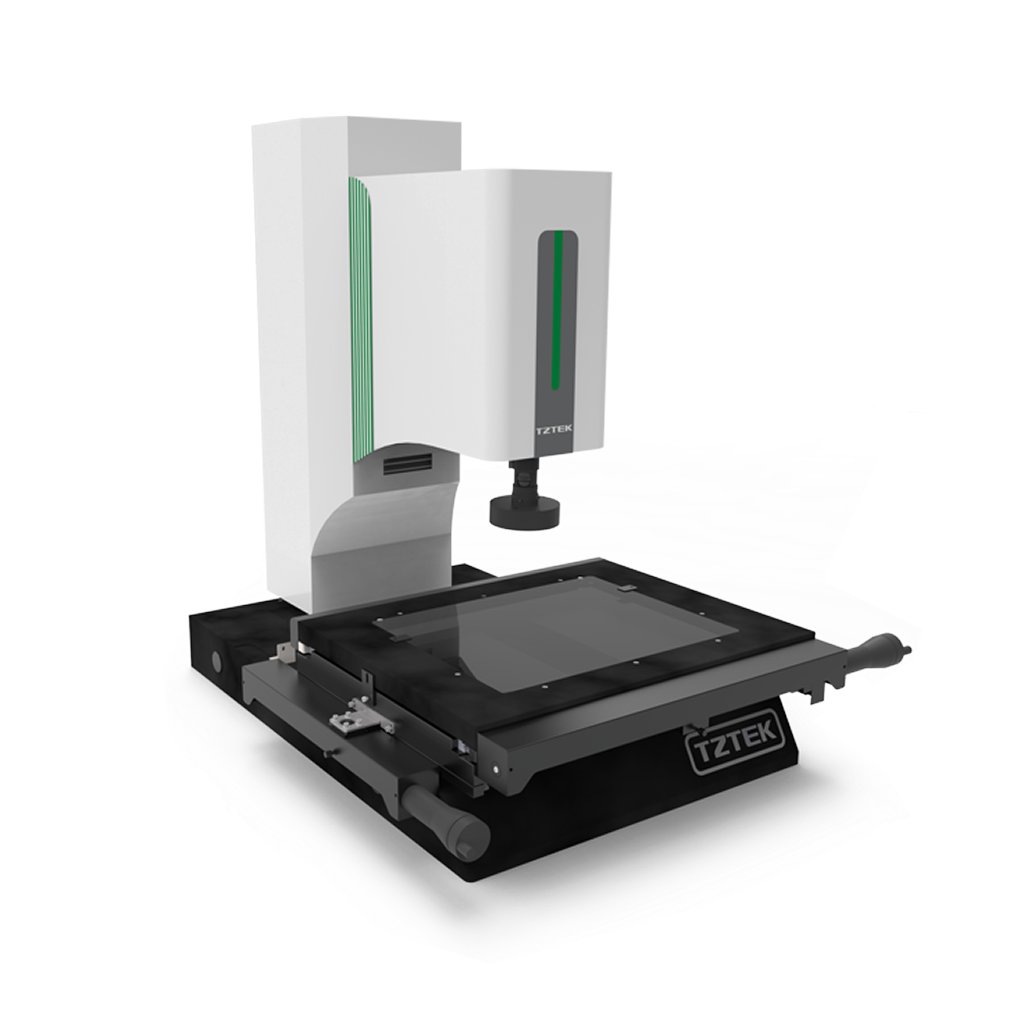

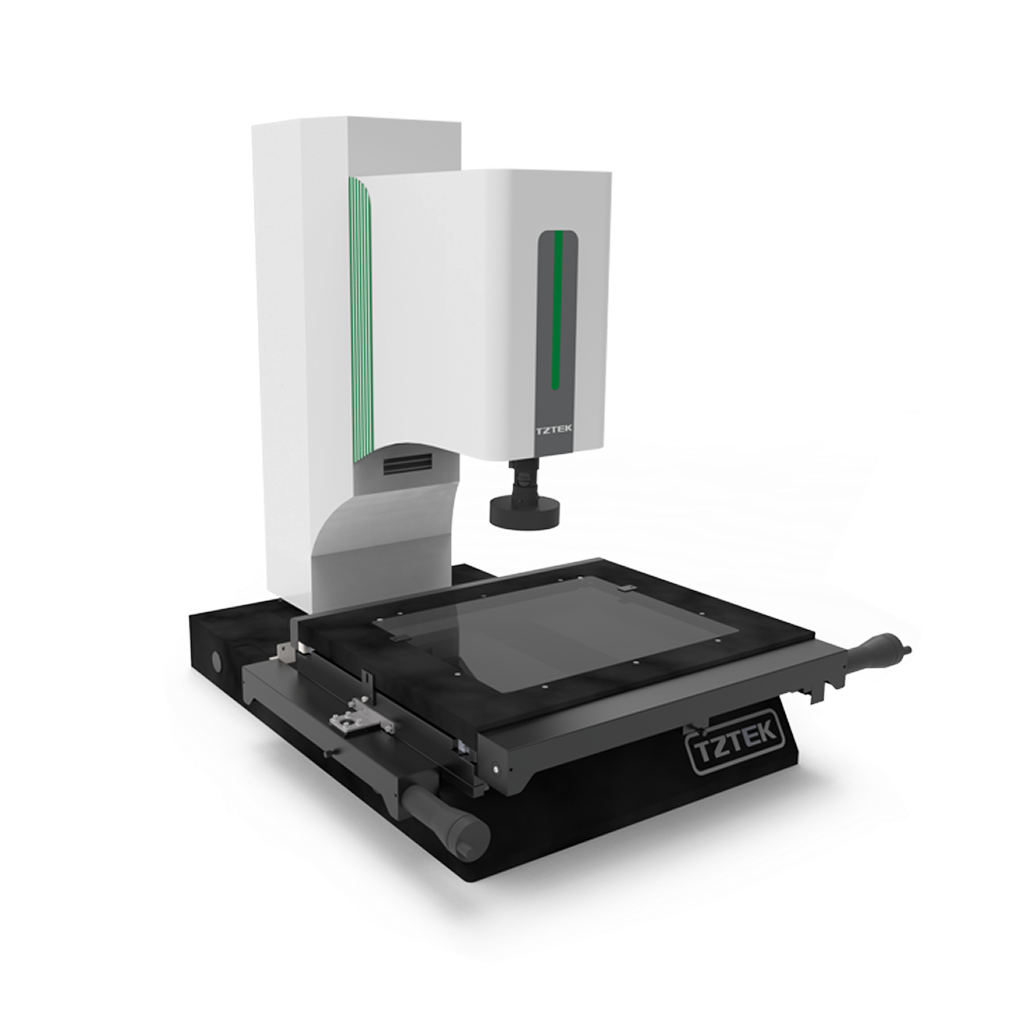

Measurement of Film Materials (VMQ)

-

Measurement Challenges

Film materials play roles such as shock absorption, waterproofing, dustproofing, thermal insulation, and soundproofing in electronic products. They are typically formed using punching processes, which require high efficiency in dimensional measurement. -

Solutions

For small-sized die-cut products, multiple products within a single field of view can be measured simultaneously. For large-sized die-cut products, moving a small platform is enough to complete the measurement of the entire product, significantly improving measurement efficiency.

-

-

Optical Module Measurement(VMU)

-

Measurement Challenges

Fiber optic communication has been widely applied in telecom networks, cable television networks, and the internet, all of which are closely related to people's lives. Optical modules are a critical part of fiber optic communication, responsible for converting optical signals. The placement accuracy of optical emitters and receivers in optical modules is crucial to reduce signal loss and interference, and to improve transmission efficiency and stability. -

Solutions

Video measuring machine equipped with an automatic zoom lens with the advantage of a large field of view at low magnification, automatically locates products and identifies serial numbers. With high magnification, the high resolution allows precise measurement of the placement accuracy of optoelectronic devices. Products in trays can be measured in batches, and measurement data is automatically uploaded to the MES system.

-

-

Laptop Shell Intelligent Measurement(VMG)

-

Measurement Challenges

Laptop shells are typically made of magnesium-aluminum alloy, and CNC processing is the main forming method. During large-scale production, environmental factors (temperature, vibration), fluctuations in machine conditions, and tool wear would change the product features. Conventional vision-based measurement requires manual feature extraction, leading to low efficiency and high labor costs. -

Solutions

During manual feature extraction, have the AI model embedded in the software and do the learning automatically. Once the learning process is complete, intelligent extraction of features and automated dimensional measurement can be achieved, significantly improving measurement efficiency and reducing labor costs.

-

-

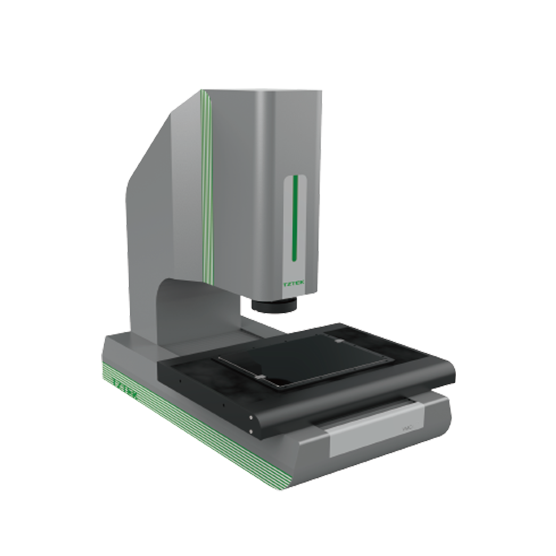

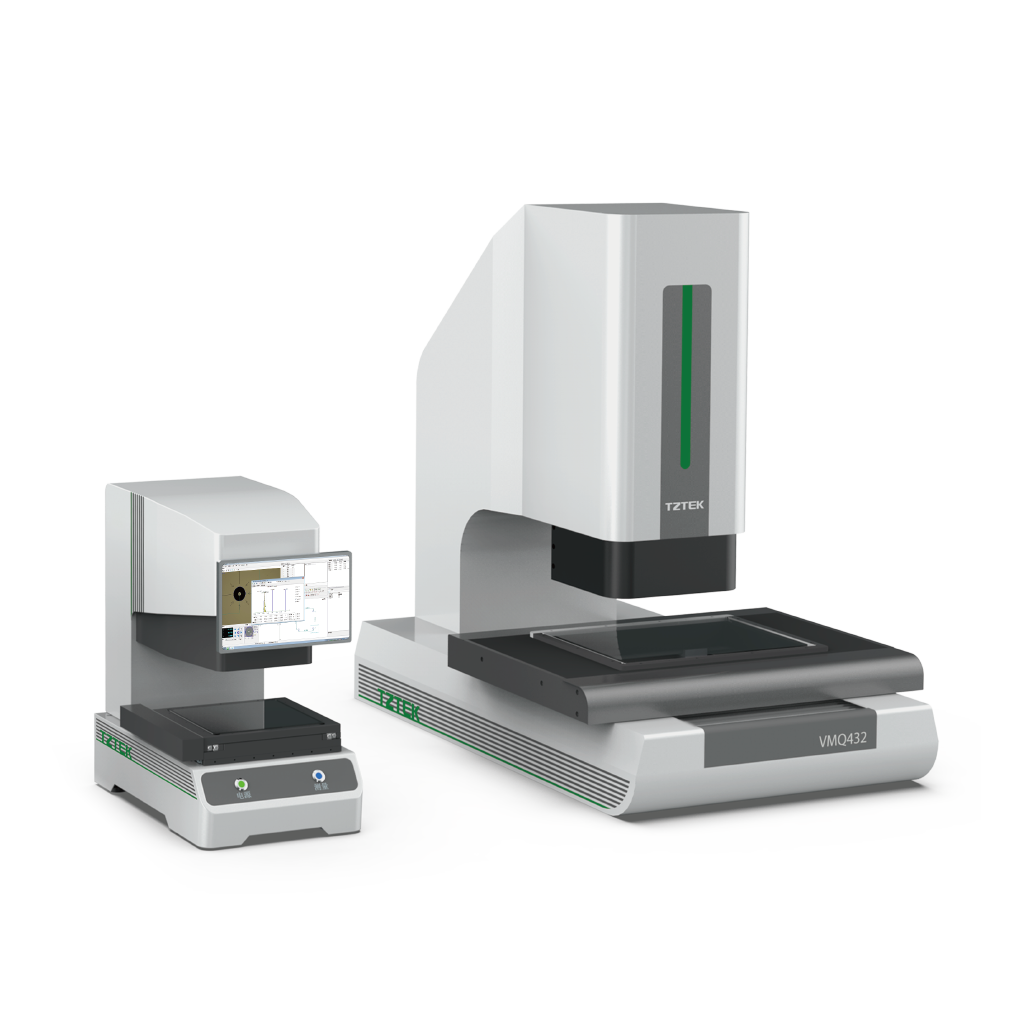

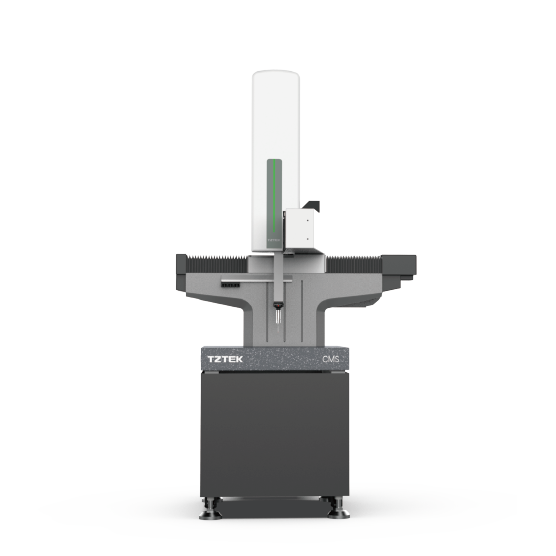

Smartphone Glass Measurement(VMQ-D)

-

Measurement Challenges

Smartphone cover glass and back glass not only enhance the aesthetics and feel of the phone but also protect internal components, assist in heat dissipation, support signal transmission, and enable wireless charging. Strict dimensional requirements are needed for cover and back glass. -

Solutions

Video measuring machine, using an automatic zoom lens in conjunction with a flash measurement lens. The flash lens, with its large field of view, quickly completes measurements of larger dimensions like the length and width of the glass. The zoom lens, with higher magnification, is used for measuring smaller dimensions, such as bevels, balancing measurement efficiency and precision.

-

-

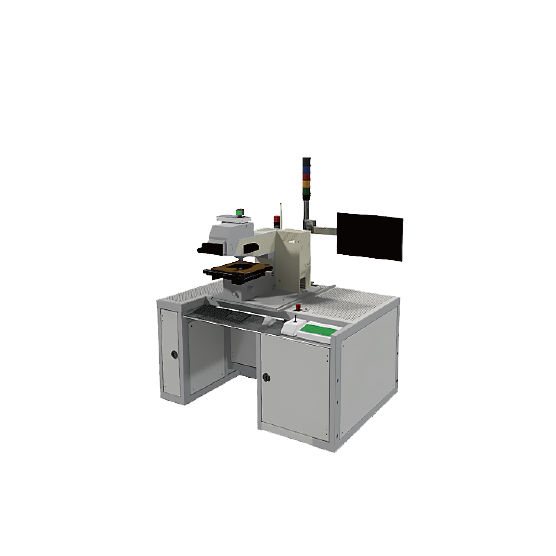

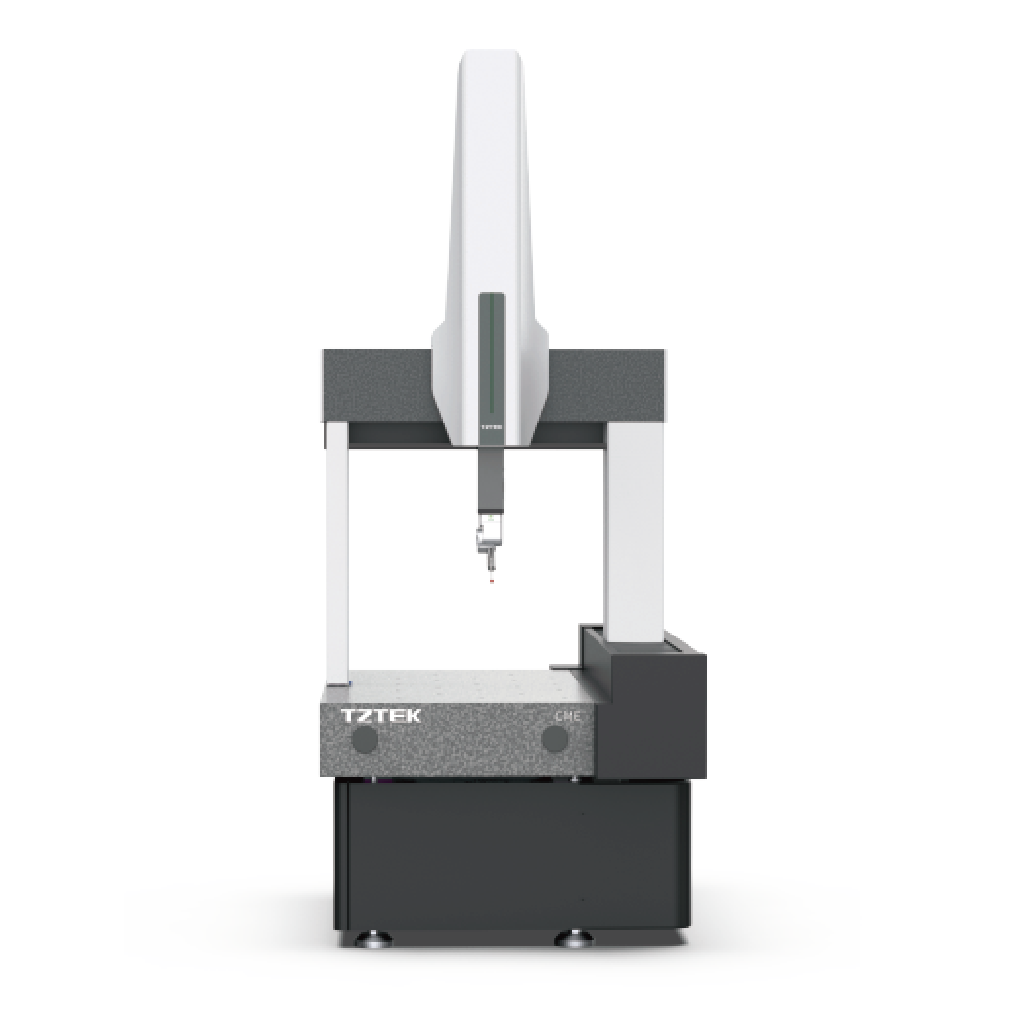

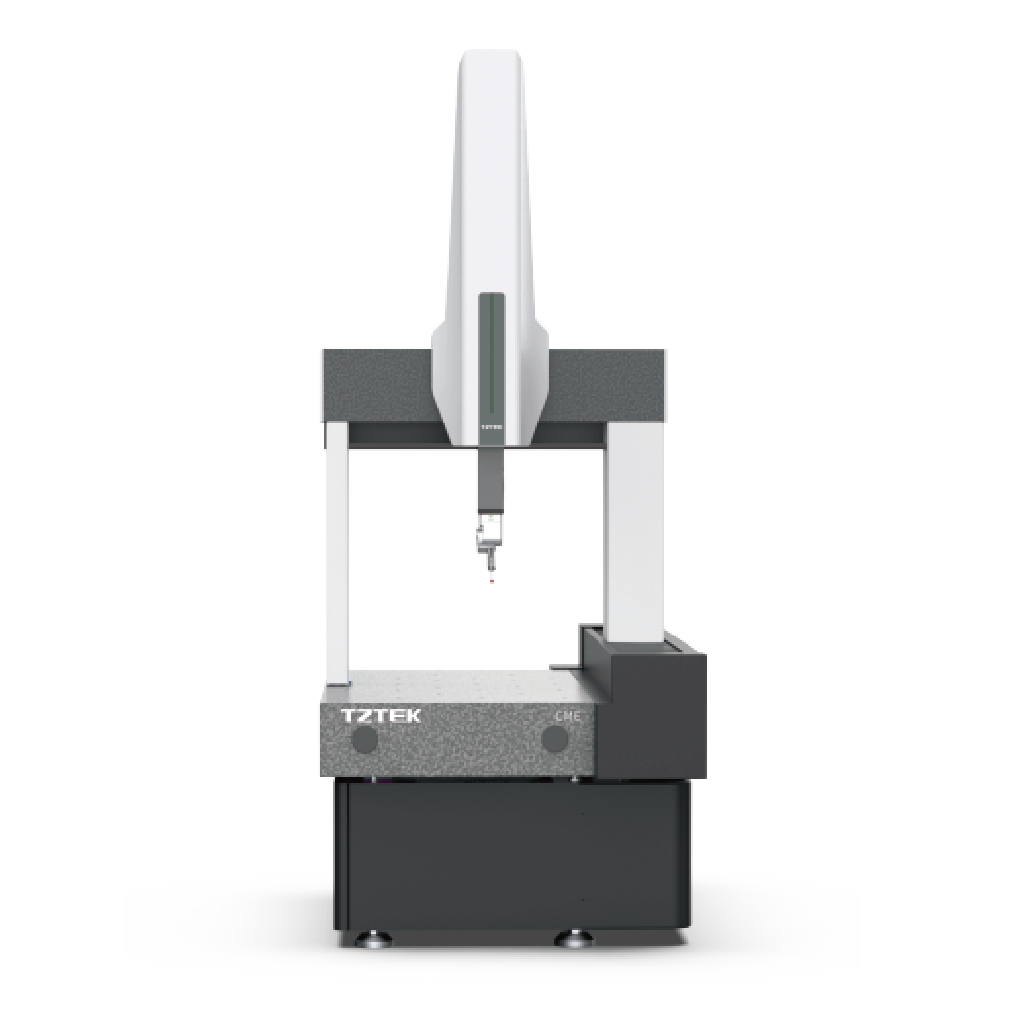

Full-Dimensional Measurement of Mobile Phone Structural Components (CME)

-

Measurement Challenges

The smartphone frame, located between the front panel and rear cover, serves to fix and support internal components. The smartphone frame is typically made of metal or plastic, processed through multiple CNC and injection molding processes, resulting in a complex and intricate structure. -

Solutions

The CMM (Coordinate Measuring Machine), equipped with a rotating measuring seat and touch probe, enables precise measurement of the all the features of smartphone frame parts throughout the entire manufacturing process, ensuring full-dimension precision.

-